High Carbon Ferro Chrome Factory Supply with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Carbon Ferro Chrome Factory Supply with Best Price

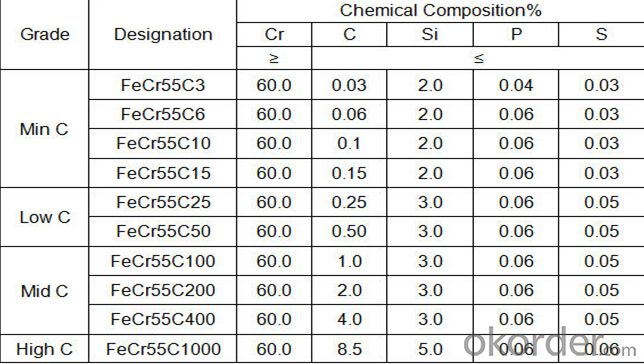

Specification of Ferro Chrome:

Pictures of Ferro Chrome:

Product Description

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- CNC carbide cutter is used to hard alloy powder and powder metallurgy mould after sintering, the hard alloy blade (blank, can not be directly used), then after grinding the surface and edge (this can be installed on the cutter head, and also can be used) in coating the surface to improve its wear resistance, have finished milling blade.The blade is machined with a special blade grinder. The price varies from a few thousand dollars to a few days depending on the size of the blade and the specificity.Surface coating is usually coated with titanium (such as titanium nitride, etc.)Large manufacturers such as diamond coating equipment general equipment in the tens of millions of yuan in cost is quite high, in Jiangsu there is a foreign company specialized in coating equipment sold to undertake external coating business, the coating cost with you a coated blade is related to the price from a few dollars to tens of dollars / piece / slice.

- Q: How to polish the rough surface of cemented carbide, what is the shortcut? Seek expert advice. Thank you。

- Polish the surface of the cemented carbide surface by using diamond abrasive paste. When polishing, can not cut short, should be in accordance with the first rough grinding paste polishing, and then use fine grinding paste polishing process, and can not be directly polished with fine abrasive paste. Otherwise, the surface of the material will leave a wavy corrugation, which will be difficult to be polished with fine abrasive. In addition, the grinding efficiency of fine grinding paste is much lower than that of coarse paste.

- Q: Where can I buy more than 94 hardness carbide cutter head, welding, the best address in detail, thank you!

- I know the downstairs Beijing Tongzhou District Yangzhuang Road No. 22 hospital Deshang with hard alloy salesroom.

- Q: The existing 60*60 standard cast iron plate, above 3 hard alloy welding specifications, probably in the 30*30, in which the appropriate welding method, know the friends willing to enlighten ah, thanks in advance.Some friends have said the binder is a copper brazing, the basic can be settled. As far as I know, many methods such as welding, high frequency welding, oxygen welding, I want to find a kind of welding method. The key is to understand the trouble with us, surface and surface welding

- Welding hard alloy is the most used for brazing, welding of copper wire.

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- if the speed in the three thousand, each Z axis 0.3 wire feed, can be a little faster, must spiral knife Oh, this is not a knife eat 5 mm. I found a 55 degree flat cutting parameters of tungsten steel milling table

- Q: What is the difference between the production process of ferrous powder metallurgy and cemented carbide?

- After the Second World War, the rapid development of powder metallurgy technology, new production technology and technical equipment, new materials and products continue to emerge, develop some special materials manufacturing field, has become an important part in modern industry.

- Q: What is the consciousness of YT in YT cemented carbide?

- YT carbide hard alloy has relatively high hardness, but poor toughness, poor impact resistance. It is suitable for processing plastic material used to machining without quenching medium and low carbon steel, alloy steel and so on.

- Q: After welding, and then sharpening, grinding into 4 Pyramid shape, and then used to knock stone, which is not easy to bad, which is more durable? Model number is D224, I would like to ask you, which should I buy? I'm mainly used for knocking stones.

- Knock stone, choose YG8, better impact and abrasion resistance,

- Q: What is the difference between hard alloy steel and high speed steel?

- 3, hardness is not the same: cemented carbide hardness, especially at high temperature hardness, but high-speed steel toughness better4, can withstand the cutting speed is not the same: due to the red hard high, can withstand higher cutting speed, and high-speed steel is now not high speed

- Q: What are the main causes of wear of high speed steel cutting tools and carbide cutting tools?

- There are two reasons1. The tool itself quality problems of our factory has been recommended 3-turn Kuwait this brand2. Just the material, good hardness of material, speed, feed, reduce the point properly, can protect the tool wear well

Send your message to us

High Carbon Ferro Chrome Factory Supply with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords