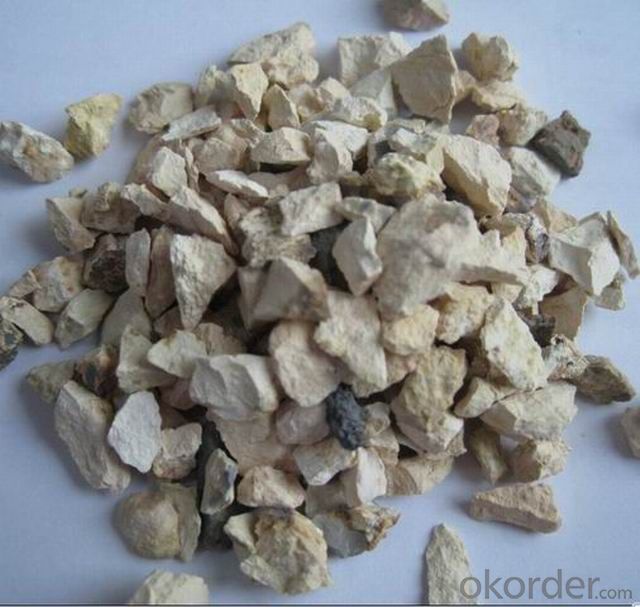

Raw Materials for Refractory - China Shaft Kiln Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 25/50 kgs/pvc bag, 1MT/big bag |

| Delivery Detail: | 12 working days after payment |

Basic Info.

Place of Origin:Zibo, China (Mainland)

Brand Name:WANFANG

Model NO.: WF-CB-1

Production Capacity: 5, 000 MTs / month

Size: Customized

Certificate: ISO 9001:2008.

Advantages

Cost advantage (Manufacturer-Direct sale);

High cost-effective;

Good fireproof insulation;

High bulk density.

Application

Widely used in aluminium metallurgy, precision casting, refractory product, ceramic fiber, alumina cement etc .

General description

As a large and class kiln & furnace expert, we also have our own raw material mine in Shanxi which is rich in bauxite so that we have the cost advantage in the engineering procurement construction of industrial kilns & furnaces. So our company is also an experienced Bauxite manufacturer. High grade calcined bauxite is used for raw material of kinds of our own refractory products.

Physical & Chemical Index

GRADE | CHEMICAL CONTENT,% | PHYCICAL PROPERTIES | ||

Al2O3 (%) | Fe2O3 (%) | DENSITY (g/cm3) | Refractoriness (℃) | |

GAL-70 | ≥70 | ≤2.0 | ≥2.75 | >1790 |

GAL-80 | ≥80 | ≤2.0 | ≥2.90 | >1790 |

GAL-85 | ≥85 | ≤1.8 | ≥3.10 | >1790 |

Remark: We could produce various sizes according to customers’ requirements.

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Who know what kind of fire shutter fire rating are there?

- The fire resistance limit of high steel structure reduces the loss of fire, achieves remarkable results. The specification is mae in order to unify the application technical requirements of the design, construction method and quality standard of the steel structure fire retardant coating, and ensure the application effect, safety. The specifications is formulated in accordance with national engineering construction of the relevant policies and "giving priority to prevention, combining fire prevention and fire extinguishing. investigated characteristics of steel structure fire in China, summed up the experience of fire resistant coating for steel structure, and absorb domestic and foreign advanced technology and scientific achievement in fire retardant coatings for steel structures, and repeatedly solicited the relevant scientific research and design, production of construction, colleges and universities, public security department

- Q: What are the standards of refractory concrete ?

- The special concrete compound by uitable binding materials, refractory aggregates, admixtures and water at a certain ratio. It can maintain the desired mechanical property at high temperature of above 900 ℃ for a long time. The property depends on the material and matching of all the aggregates, admixtures and binding materials. Its material, composition and ingredients are similar to these of refractory castable. Refractory aggregate can be dry slag, broken refractory bricks, basalt, bauxite, magnesite, etc. According to the binding material, it can be divided into Portland cement refractory concrete, aluminate cement refractory concrete, sodium silicate refractory concrete, phosphate refractory concrete, magnesia refractory concrete, etc. (8) The particle material and powder material in refractory concrete are called aggregate and admixture respectively. The mixture of concrete can be moulded by casting, vibrating or ramming. And proper measures to promote their hardening can be used in accordance with the hardening characteristics of the binding materials (such as air hardening, water hydraulicity, thermal hardness, etc.). It is mainly used to build the monolithic lining of industrial furnace and procast blocks. Of all the concrete, the ones used for under 900 ℃ is called heat-resistant concrete, and they are used for the foundation and chimneys, etc. of industrial furnaces and thermal equipment.

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- What you said is the pixel! Only that has b1b2. Level b1 is the fireproofing level b1, because the particle does not belong to the fireproofing material. Only can fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name.

- Q: What are the characteristics of magnesium fireproof plate

- Fire Excellence: Glass magnesium plate is non combustible plate having good fire-resisitance quality. Flame will never burn continuously on it. It does not catch on fire when temperature reach 800 ℃, and will not be lit up at 1200 ℃. The plate, having high-quality keel partition system, is rated as the highest non-combustible level A1 with fire resistance being above 3 hours. It absorbs a lot of heat when fire is burning, delaying rise of ambient temperature. Waterproof and moisture proof: Glass magnesium plate functions steadily whenever weather is dry and cold or humid and damp, not influenced by condensed water drop and moist air. Even air dried after soaked in water for a few days, no deformation, it will not go out of shape, turn soft, or absorb moisture After testing, the board has no water permeability. Light weight and seismic resistance: Low overall plate density of 0.8-1.2g/cm3 reduces the building's load, and the weight of building interior wall by over 60%, and increases the use area by 5-8%. Its lightweight is conducive to anti-seismic, can effectively reduce main cost of foundation and structure. Superior strength: Magnesite has special 5.1.8 phase covered fiberglass cloth and good toughness of plant fiber. Altough glass magnesium fireproof plate is light, it has tight structure, good stability, wood-like toughness, outstanding performance in impact resistance, compressive strength, tensile strength equal rigidity and toughness, with flexural strength up to 322kgf\cm2 (vertical) and 216kgf\cm2 (level of) as well as impact strength of 25MPa.

- Q: The following statement is correct: artificial corundum has a high melting point and can be used as a high grade refractory material. The main component is silica dioxide

- It's D,1. artificial corundum is mainly composed of three aluminium oxide two4, color glasses are not added cuprous oxide, silver halide is added

- Q: Who knows about the grade C fireproof door materials?

- Wood or steel materials are usually used in them. The new national standard fire doors: According to the enacted GB12955-2008, the fire endurance of grade C fire doors is 0.5 hours and that of grade A and B are 1.5 hours and 1.0 hours respectively.

- Q: I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- High enough for high temperature resistance. Refractory materials for crucibles shall be subjected to a high temperature greater than 1700 DEG C and the softening temperature shall be greater than 1650 DEG c;

- Q: What are the chemical composition of refractory cement?

- Calcium aluminate prepared by calcining as the main component. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement.

- Q: The principle of choosing fire-resistant material in Thermal Energy and Power Engineering equipment.

- What thermal equipment? The most simple principle is durable, low cost and with no environmental pollution.

- Q: What is refractory?

- Refractory materials are widely used in metallurgy, machinery manufacturing, chemical industry, petroleum, power and other industrial fields. It is an inorganic nonmetallic material mostly used in metallurgical industry with the minimum refractoriness of 1580 ℃, able to resist high temperature without softening (annealing). It accounts for 50% to 60% in total output. Refractoriness refers to refractory's ability to resist fire.

Send your message to us

Raw Materials for Refractory - China Shaft Kiln Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords