Raw Materials for Refractory:Rotary Kiln/ Shaft Kiln Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rotary Kiln/ Shaft Kiln Calcined Bauxite

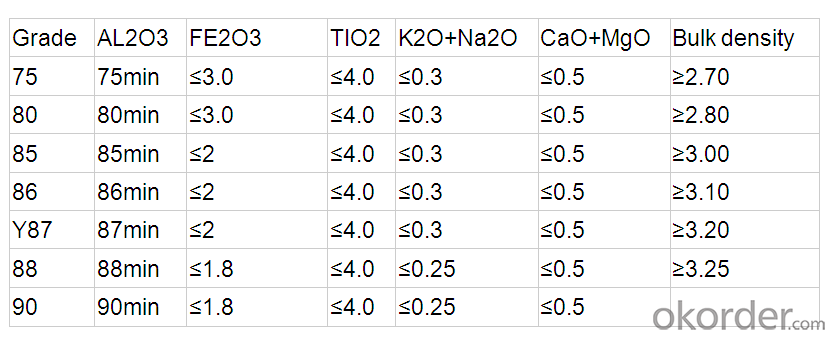

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

High grade calcined bauxite used for raw material of kinds of refractory products and monolithic series.

Usage

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

6. Producing bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemistry industry for all kinds of aluminium compound.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What is the main constituent of refractory brick?

- There are several refractory bricks, including clay brick, carborundum brick and chromium-carbon. The type you said may be refractory bricks made from bauxite.

- Q: What's the maximum temperature that the high-temperature resistant refractory ceramic fiber cotton can endure?

- Nichrome wire, stainless steel wire and glass fiber are reinforced. Ceramic fiber coating cloth and slag cloth, sintering ceramic fiber cloth and ceramic fiber fumigation cloth) Characteristics of the ceramic fiber cloth: high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment; Applications of ceramic fiber cloth: It can be applied to the thermal insulation of all kinds of furnaces, high-temperature pipelines and vessels; furnace doors, valves, flange seal, fire doors, fire resisting shutters and high-temperature furnace door curtains; engine and instrument insulation, clad material of fireproof cables, and high-temperature resistant and fire-proof materials; thermal insulation cloth for coverage, high-temperature expansion gap padding, and inner linings of the flue; high temperature resistant labor safety products, fireproof suits, high-temperature filtration and sound absorption, replacement of asbestos, etc.

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- High alumina brick, clay brick, brick and other high-quality refractory products, widely used in metallurgy, building materials (cement and glass), non-ferrous metal smelting, petroleum, chemical, electric power, machinery manufacturing and other industries.

- Q: For refractory knowledge. What is the ratio of clay ramming?mass?

- Soil aggregates, dispersing agent, water reducing agent, plasticizer, binding agent and powder! ~ Bone meal feed approximately 6, OK

- Q: Is the ball mill used in production of refractories?

- Refractory is a kind of non-metallic material that is of resistance to thermal shock and chemical erosion, low thermal conductivity and low expansion coefficient. The refractoriness of the refractory is not less than 1580℃. The usage of the refractory is broad. Refractory materials include refractory bricks and powders. Abandoned refractory bricks can be recreated as new bricks after they are crushed by a crusher and grinded by a ball mill. The ball mill and crusher are needed to grind and crush the material in the production of the refractory. The ball mill produced by Zhengzhou Xinhai Machinery Manufacturing Co. has excellent performance and there are many successful cases in Inner Mongolia, Heilongjiang and Guangdong. At the request of the national environmental policy, the company adjusts the equipment details, allowing the equipment to ensure the volume of production while reduce energy consumption.

- Q: What kind of refractory materials should be used for the intermediate frequency furnace to smelt manganese?

- I’d like to make supplements to upstairs that aluminum silicate refractory materials should be needed considering heat insulation.

- Q: What are the requirements of the performances of brasque refractory?

- Physical properties of refractory include structural properties, thermal properties, mechanical properties, usability and operation property. The selection of the brasque refractory must have the following characteristics: 1. properties of not distortion and not melting at sufficient temperatures 2. have the necessary structural strength at high temperatures and does not soften and deform 3. must keep stable volume at high temperatures and will notcrack caused by expansion and contraction 4. will not rapture and flake when temperature is drasticly changed or heated unevenly 5. resistant to chemical erosion of metallic solution, slag and furnace gas, etc.

- Q: Who knows which chrome refractories produced by the Henan refractory plant can be used for continuous casting?

- Field casting experiments are needed to verify,

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: What is the mechanism of the errosion of the iron to the refractories?

- For example, the effect of the iron oxide: Mo corundum given temperature Fe2O3 solid solubility limit of the solid solution formed of corundum stone high solubility than the solid solution Mo Mo corundum lattice shape so Fe2O3Al2O3-SiO2-based material starts melting temperature of the system or the content of Al2O3 and Al2O3 / SiO2 ratio off Al2O3 / SiO2 & lt; 2.55 starting melting temperature of 1380 ℃ when Al2O3 / SiO2 & gt; 2.55 start melting temperature is increased 1460 ℃ and with its Al2O3 content increased gradually to increase the original atmosphere Fe2O3 original FeO off the solvent into the glass phase and the system starts melting temperature drops do not fall to 1240 ℃ 1380 ℃. Lower the melting point, increase the erosion, and reduce the life span.

Send your message to us

Raw Materials for Refractory:Rotary Kiln/ Shaft Kiln Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords