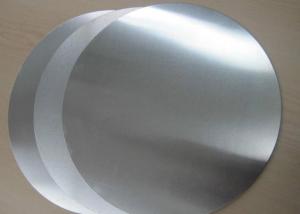

China Pvdf Coated Aluminum Coil - AA3003 Aluminum Circles Suitable for Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum circles /sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: Can aluminum coils be welded or joined?

- Yes, aluminum coils can be welded or joined. Aluminum welding involves melting the edges of the coils and fusing them together using a welding technique such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Aluminum can also be joined by other methods like brazing or soldering.

- Q: What are the typical delivery options for aluminum coils?

- Delivery options for aluminum coils can vary depending on the supplier and customer's requirements. However, there are several common options available. 1. Direct delivery: Many suppliers offer the convenience of delivering the coils directly to the customer's location. This is particularly useful for customers who need large quantities or have limited transportation capabilities. The supplier will make arrangements for transportation, using trucks or shipping containers, to deliver the coils directly to the customer's facility. 2. Pickup from supplier: Customers also have the choice of arranging their own transportation and collecting the aluminum coils from the supplier's location. This option is often preferred by customers who are located nearby or already have their own transportation logistics in place. 3. Third-party logistics (3PL): Some suppliers collaborate with specialized logistics companies to handle the delivery of aluminum coils. These companies have expertise in transportation and offer efficient and cost-effective delivery services. Customers who prefer to outsource their logistics operations often choose this option. 4. International shipping: Customers requiring international delivery of aluminum coils have the option of using air or ocean freight. However, these methods may involve additional costs and longer delivery times due to customs clearance and transportation logistics. It's important to note that the specific delivery options may vary depending on the supplier's capabilities and the customer's location. Therefore, it is recommended to directly discuss delivery options with the supplier to ensure the most suitable and cost-effective method is chosen.

- Q: What are the common sizes of aluminum coils?

- Common sizes of aluminum coils vary depending on the specific industry and application. However, some standard sizes are commonly used across different industries. For the construction industry, common sizes of aluminum coils range from 0.018 inches to 0.032 inches in thickness and can have widths from 12 inches to 60 inches. These coils are typically used for roofing, siding, and gutter applications. In the automotive industry, aluminum coils are often used for manufacturing various parts, such as body panels and structural components. The sizes of these coils can vary greatly, ranging from thin strips for small parts to larger coils with widths of up to 72 inches for larger components. For the packaging industry, aluminum coils are used to produce foil products, such as food packaging and industrial packaging. The thickness of these coils can range from 0.00017 inches to 0.0005 inches, while the widths commonly range from 12 inches to 24 inches. It's important to note that these are just some of the common sizes, and specific applications may require custom sizes of aluminum coils. Additionally, manufacturers often have the capability to produce coils in various sizes to meet the specific needs of their customers.

- Q: Is it okay to combine copper with aluminum in case of minting or coin making? Thanks :)

- i think its fine

- Q: Is it possible to recycle old aluminum coils as scrap metal?

- <p>Yes, old aluminum coils can be used as a source of scrap metal for recycling. Aluminum is a highly recyclable material, and recycling it helps conserve resources and energy. Old aluminum coils can be melted down and repurposed into new aluminum products. It's important to ensure that the coils are clean and free of contaminants before recycling to maintain the quality of the recycled aluminum. Always check with local recycling centers or scrapyards for specific guidelines on recycling aluminum coils.</p>

- Q: What are the uses of aluminum coils?

- Aluminum coils have a wide array of applications in various industries. HVAC systems and air conditioning units heavily rely on aluminum coils for their heat transfer and air cooling functions. These coils are indispensable components in these systems. Moreover, the construction industry frequently utilizes aluminum coils for roofing, cladding, and insulation purposes. Their lightweight nature, durability, and resistance to corrosion make them perfect for outdoor applications. The automotive industry also incorporates aluminum coils in the production of vehicles. These coils are used in the manufacturing of various parts, including radiators, heat exchangers, and condensers, owing to their exceptional heat transfer properties. The packaging industry extensively depends on aluminum coils as well. These coils are employed in the production of cans and containers for food and beverages. Aluminum is an excellent choice for packaging due to its lightweight nature, recyclability, and ability to provide a barrier against moisture, oxygen, and light. This ensures the quality and freshness of the enclosed products. Furthermore, aluminum coils find applications in electrical wiring, where they serve as conductors due to their high electrical conductivity. They are also used in the production of electronics like laptops, smartphones, and tablets, as they possess excellent heat dissipation properties. In conclusion, the uses of aluminum coils span across a diverse range of industries, including HVAC systems, construction, automotive, packaging, and electrical applications. The versatility, durability, and exceptional properties of aluminum make it a favored material choice in numerous sectors.

- Q: Are aluminum coils suitable for reflective insulation?

- Yes, aluminum coils are suitable for reflective insulation. Aluminum is highly reflective and has low emissivity, which means it can effectively reflect radiant heat. This makes it an ideal material for reflective insulation, as it helps to reduce heat transfer by reflecting radiant energy away from the insulated space. Aluminum coils are commonly used in reflective insulation products such as foil-faced insulation boards and radiant barriers.

- Q: im melting aluminum and what should i use for metal. cans will just oxygenize( i forget the word for it sorry)

- aluminum, in general, will just oxidize if heated in air. it is not just cans that behave that way when they (alcan, alcoa) smelt aluminum industrially they keep it in a reducing environment and do not allow molten aluminum to contact air. so use any aluminum you like but prevent it from contacting air.

- Q: Hi i need to know what will happen to the impact strength of aluminum 2024 reinforced with Silicon carbide is treated to cryogenic temperature (nearly -200C). Will impact strength increase or decrease. Also will the impact strength vary with respect to the percentage of Silicon carbide.

- Aluminum 2024 doesn't have a transition temperature, it absorbs about 18n-m impact strength (via charpy tests I ran three weeks ago at my College course). This was constant between -150?C to +150°C (liquid nitrogen to a furnace). This excerpt from wiki: Cutting tools In 1982 at the Oak Ridge National Laboratories, George Wei, Terry Tiegs, and Paul Becher discovered a composite of aluminium oxide and silicon carbide whiskers. This material proved to be exceptionally strong. Development of this laboratory-produced composite to a commercial product took only three years. In 1985, the first commercial cutting tools made from this alumina and silicon carbide whisker-reinforced composite were introduced by the Advanced Composite Materials Corporation (ACMC) and Greenleaf Corporation. Leads me to believe it depends on how you mix the material in would make a difference. Silicon Carbide and aluminum make very strong tools, but would make it more brittle. The ceramic in a metallic crystal lattice (metal is a crystalline structure) would allow more voids to coalesce leading to a brittle fracture, but the initial strength would be improved because of substitution dislocations in the crystal structure (it would be more rigid, stronger, but more prone to sudden failure). Silicon carbide has low thermal expansion coefficient compared to aluminum also so when it gets really cold the aluminum would contract around the particles increasing the strength, but again, reducing ductility and causing fractures to occur more rapidly. Anyways, very interesting, you should do a bit of research on your own after this as I gave you some good places to work from (and I'm sure plenty of words to look up ;D )

Send your message to us

China Pvdf Coated Aluminum Coil - AA3003 Aluminum Circles Suitable for Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords