China Hot Rolled Steel coils Cold Rolled Steel Coils Grade 304 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

China Hot Rolled Steel coils Cold Rolled Steel Coils Grade 304

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

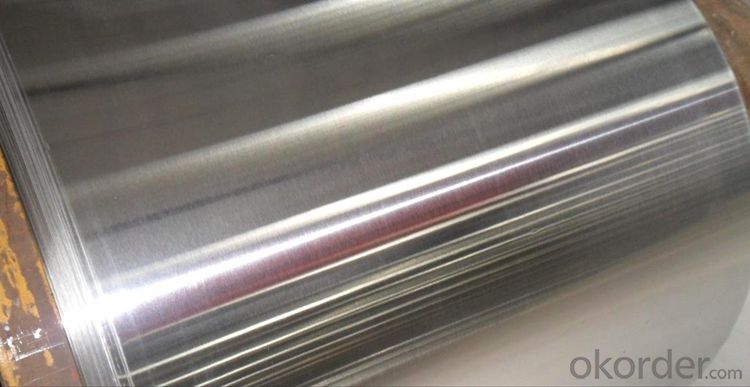

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 15-20 days after deposit or according to the order quantity |

Detail picture of Products:

Application

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

- Q: Are stainless steel sheets magnetic?

- Yes, stainless steel sheets can be magnetic. The magnetic properties of stainless steel sheets depend on their composition. Generally, stainless steel is a non-magnetic material. However, certain grades of stainless steel, such as the 400 series (e.g., 410, 416, 420, and 430), contain a higher amount of ferritic or martensitic structures, which can exhibit magnetic properties. On the other hand, the commonly used 300 series stainless steel (e.g., 304 and 316) is non-magnetic due to its austenitic structure. Therefore, it is important to consider the specific grade of stainless steel when determining its magnetic behavior.

- Q: Can stainless steel sheets be used for architectural railings?

- Indeed, architectural railings can make use of stainless steel sheets. Due to its durability, resistance to corrosion, and pleasing appearance, stainless steel is widely chosen as a material for architectural railings. One advantage is that stainless steel sheets can be specifically tailored and molded into diverse sizes and designs to meet the precise demands of each architectural railing project. Moreover, stainless steel sheets offer various finishing options, including brushed, polished, or textured, allowing for the desired visual effect to be achieved. All in all, stainless steel sheets are a dependable and adaptable option for architectural railings, offering both practicality and aesthetic allure.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is a preferred material in cleanroom environments due to its inherent qualities such as corrosion resistance, durability, and ease of cleaning. It is non-porous, making it resistant to bacteria, mold, and other contaminants. Additionally, stainless steel is able to withstand frequent sanitization procedures without deteriorating, making it a reliable choice for maintaining a clean and sterile environment in pharmaceutical cleanrooms.

- Q: How do I prevent warping on stainless steel sheets?

- To prevent warping on stainless steel sheets, it is important to ensure proper handling and storage practices. Avoid placing heavy objects on top of the sheets, as this can cause them to bend or warp. Additionally, store the sheets in a clean and dry environment to prevent moisture absorption, which can also lead to warping.

- Q: Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is a popular choice for water tanks due to its corrosion-resistant properties. It is highly resistant to rust and can withstand exposure to water and moisture without deteriorating. Stainless steel is also hygienic, as it does not react with water or leach any harmful substances into it. Additionally, stainless steel tanks are durable and long-lasting, making them a reliable option for storing water. Overall, stainless steel sheets are a suitable material for constructing water tanks, providing a safe and reliable storage solution for water.

- Q: What are the different sizes available for stainless steel sheets?

- Stainless steel sheets are available in various sizes, ranging from small sheets measuring a few inches in width and length, to larger sheets that can be several feet wide and long. The specific sizes available depend on the manufacturer and the intended use of the stainless steel sheets.

- Q: How do you prevent staining or discoloration on stainless steel sheets in coastal environments?

- To prevent staining or discoloration on stainless steel sheets in coastal environments, it is essential to regularly clean and maintain the surface. This can be done by using mild detergents or stainless steel cleaners to remove any salt, dirt, or other contaminants. Additionally, applying a protective coating or a high-quality wax can help to create a barrier against the corrosive effects of salty air and moisture. Regular inspections and prompt removal of any signs of corrosion or staining are also vital to prevent further damage.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets are contingent upon several factors, including the stainless steel grade, sheet thickness, and the specific bending process employed. Stainless steel sheets are renowned for their exceptional strength and durability, enabling them to be bent to a certain degree without fracturing or breaking. As a general rule, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For instance, a 1mm thick sheet can typically be bent to a minimum radius of 2mm. It is crucial to note, however, that this is merely a general guideline, and the actual bending limits may differ based on the particular stainless steel grade. Certain stainless steel grades, such as 304 and 316, possess higher yield strengths and greater resistance to deformation, rendering them suitable for more demanding bending applications. Thicker sheets also exhibit higher bending limits in comparison to thinner ones, as they possess more material to withstand the forces of bending. Moreover, it is important to mention that the chosen bending process can impact the bending limits of stainless steel sheets. Press brake bending and roll bending are commonly employed methods for bending stainless steel sheets. These processes employ distinct techniques and equipment, resulting in varying bending limits. To ascertain the exact bending limits for a specific stainless steel sheet grade and thickness, it is advisable to refer to the manufacturer's specifications or seek guidance from a professional metal fabricator. They possess the expertise and knowledge to provide precise information and guidance on the bending capabilities of stainless steel sheets tailored to your specific application.

- Q: What are the different types of stainless steel sheet finishes for automotive applications?

- There are several different types of stainless steel sheet finishes that are commonly used in automotive applications. These finishes are designed to provide both aesthetic appeal and functional benefits for the automotive industry. 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a rough, dull appearance. It is commonly used in non-decorative applications where corrosion resistance is the primary concern. 2. No. 2B Finish: This is a bright, cold-rolled finish that is commonly used for automotive trim and decorative applications. It has a smooth surface and a moderate level of reflectivity. 3. No. 3 Finish: This is a semi-polished finish that is achieved by using progressively finer abrasives. It has a moderate level of reflectivity and is commonly used for decorative applications where a shinier appearance is desired. 4. No. 4 Finish: This is a brushed finish that is achieved by polishing the stainless steel sheet with a fine-grit abrasive. It has a consistent, linear grain pattern and a moderate level of reflectivity. It is commonly used for decorative applications such as trim and accents. 5. No. 8 Mirror Finish: This is a highly polished finish that is achieved by buffing the stainless steel sheet with a series of abrasive compounds. It has a mirror-like appearance and is commonly used for decorative applications that require a high level of reflectivity. In addition to these standard finishes, there are also specialty finishes available for automotive applications, such as embossed, patterned, or textured finishes. These finishes can provide unique design elements and enhance the overall aesthetic appeal of the vehicle. Overall, the choice of stainless steel sheet finish for automotive applications depends on the specific requirements of the project, including factors such as corrosion resistance, durability, and desired appearance.

- Q: Can stainless steel sheets be custom-cut?

- Stainless steel sheets have the capability to be tailored to specific sizes and dimensions. This adaptable material can be easily molded and formed to meet individual needs. The custom-cutting of stainless steel sheets is widely practiced across multiple industries, including construction, manufacturing, and fabrication. This procedure guarantees a precise fit for various purposes, such as architectural projects, machinery components, or kitchen equipment. Expert metal fabricators or specialized service providers commonly employ advanced techniques like laser cutting, waterjet cutting, or shearing to accurately customize stainless steel sheets according to desired specifications.

Send your message to us

China Hot Rolled Steel coils Cold Rolled Steel Coils Grade 304 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords