CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | Medium Temperature |

Media: | Water | Port Size: | DN50-400 | Place of Origin: | China (Mainland) |

Model Number: | H76X | Brand Name: | CMAX | Application: | General |

Name: | Single disc wafer type check valve | Standard: | API,DIN,JIS,BS, | Medium: | wafer,oil,gas,Acid,alkali |

Valve body material: | cast iron,Stainless steel,brass | Size: | 2"~16" or DN50~DN400 | Advantage: | no leakage |

Packaging & Delivery

Packaging Details: | Veneer board boxes |

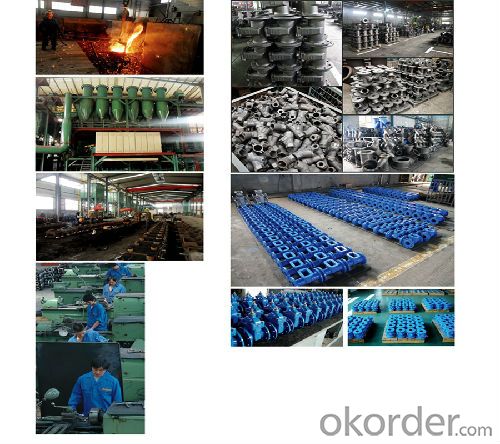

Name:Wafer type check valve,single door check valve,wafer type swing check valve.

Valve body:cast iron ,GG25,GGG40,CF8M

1.Working pressure:1.6Mpa

2.Testing :API598 DIN3230

3.Flange standard

DIN2501 PN10/16

BS4504 PN10/16

BS10 TABLE "D"/"E"

JIS2220 10K/16K

ANSI125/150

4.Face to face

ANSI125/150

DIN3203 K3-1999

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

- Q: Is the check valve behind or behind the gate valve? Why?

- Thank youPlease install it in frontWhat about the front?

- Q: What's the difference between a stop valve and a check valve? Is it a valve?

- A check valve is a valve that automatically prevents the flow of fluid. The disc of the check valve is opened under the action of fluid pressure, and the fluid flows from the inlet side to the outlet side. When the inlet side pressure is lower than the exit side, the valve automatically closes under the influence of fluid pressure, gravity and other factors to prevent fluid flow backwards. The function of this type of valve is to allow the medium to flow in one direction and to prevent flow in the direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow. Among them, the check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface.

- Q: Should the kitchen check be mounted on the wall or on the hood?

- Buy their own check valve is generally in the wall of the hole, the hood of the smoke machine, usually with a check valve.

- Q: Pump adapter need check valve?

- Multifunctional pump combination device usually comes with safety valves and check valves, usually in the flange pipe interface or who is interface settings simple check valve, safety valve is white, but does not apply to the north, the northern cold, need to separate the pipes below plus a check valve, a higher temperature of the South may be suitable for direct use of non frozen.

- Q: Can the check valves fit two in one tube? One up, the other down

- A water pipe is used for launching, and the two check valves that you install are reverse, and the water is blocked by one of the check valves on either side

- Q: What kind of valve does the check valve belong to?

- 1. check valves are automatic valves;2., if the valve is cast iron, can be cast iron valves; if the valve is cast steel, can be cast steel valves; of course, can also beIn copper valves, stainless steel valves,,,,,,,3., if used in steam, can belong to the steam valve

- Q: Does the check valve damage affect the flow rate?

- Ball check valve will not affect the flow, such as the clip type check valve once damaged, it will affect the flow.

- Q: What are the main types of check valves?

- Check valve (Check Valve):1, according to the structure, can be divided into lifting check valve, swing check valve and butterfly check valve three.The lift check valve can be divided into two types: vertical and horizontal.Swing check valve is divided into single, double valve and multi flap type of three.Butterfly check valve is straight through type.These types of check valves can be divided into three types: thread connection, flange connection and welding.

- Q: What is the difference between the check valve and the check valve?

- The same thing is the flue check valve. We need to contact the manufacturer

- Q: Can the exhaust air outside the wall be fitted without a check valve?

- What you are talking about is the backflow blower of the exhaust fan. This is usually installed. It is a method of preventing the air stream from returning under the condition that the fan stops running. If your fan is only a common wall exhaust, you can not install it, but if it is a discharge of air pollution or dilution of dangerous air flow, then advise you to install it as well.

Send your message to us

CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords