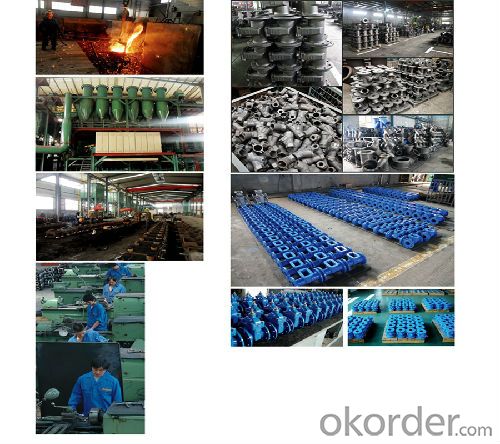

CHECK VALVE LIFT TYPE DUCTILE IRON DIN DN15- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

Model Number: | CMAX | Brand Name: | CMAX | Application: | General |

Name: | iron water lift check valve | Connection: | Flange | Temperature: | ≤425℃ |

Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

Certification: | ISO,CE | Warranty: | 12 month |

Packaging & Delivery

Packaging Details: | standars export wooden for Alibaba Bell DN100 adjustable cast iron water lift check valve |

Delivery Detail: | 20 days |

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

- Q: Why can't parallel check valve be installed firmly?Anonymous browsing | 51 times

- The vertical installation is easy to cause the valve core of the check valve to clamp off or fall off, and lose the function of checking back. The direction of the check valve is restricted seriously from any direction of the medium

- Q: Which type of check valve should be selected for vertical pipes?

- The check valve on the vertical pipeline shall ensure that the spool goes back to its position when the fluid is stationary and reversed.Optional:Butterfly check valves, pipes of low pressureVertical lift check valve, high pressure resistance, good tightnessSwing check valve: flow must be from the next up, the pipe diameter is unlimited

- Q: Is the hdf41x 1.6Mpa a check valve?

- The hdf41x 1.6Mpa is a backflow preventer with a check valve that is stronger and more complex than the function check valve.Backflow preventer (backflow preventer) is a device that uses a check element to prevent backflow of water supply pipe.

- Q: Back pressure valve and check valve difference

- Oil is generally put into the wells of the check valve calling back pressure valveCheck valve is a general name, mainly lifting type and swing type.

- Q: How can the lift vertical check valve be distinguished from the lift horizontal check valve?

- The check valve is divided into three kinds: lift check valve, swing check valve and butterfly check valve. The lift check valve can be divided into two types: vertical and horizontal. Swing check valve is divided into single, double valve and multi flap type of three. Butterfly valve for the straight through, the above non-return valve can be divided into connection, flange and welding of three lift check valve and stop valve structure similar to the thread in the form of connection, the valve in a line along the channel for the lifting movement, reliable action, but the fluid resistance is large. Small in diameter for the occasion. Lift check valve can be divided into straight and vertical two kinds. Straight through lift check valve can only be installed in horizontal pipe, vertical lift check valve is usually installed in vertical pipe. You can see the picture in Baidu's picture

- Q: Our unit pump outlet check valve installed in the vertical pipe, the use of the valve to stop the valve is more serious impact, is not installed, the valve should be how to install it?

- Installation method of pump outlet check valve:1, swing check valve is generally installed in the horizontal pipe: for caliber DN~80mm check valve, can also be installed in theVertical or upward sloping pipe.2, the straight through lift check valve should be installed on the horizontal pipe;3, vertical lift check valve must be installed on the vertical pipe, the medium for bottom-up flow.As the check valve is easy to damage, therefore, should be installed near the pump outlet valve, in the upper part of the check valve with a cut-off valve (general use of ball valve or gate valve), easy to overhaul. To facilitate the relief of the check valve before disassembly, the relief valve shall be installed between the check valve and the shut-off valve.

- Q: How to prevent the backflow valve of medium

- Check valve operating principleCheck valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. The check valve can be mainly divided into swing check valve (rotating by gravity center) and lift check valve (moving along the axis).

- Q: What does the swing check valve "h44h-16" mean?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q: What about boiler non-return valve without return?

- There are two reasons: 1 pipe dirty, need to clean up.2 pressure difference between the two sides of the valve, see the pressure on both sides is how much?

- Q: How to install fire fighting pipe and flue fire check valve?

- 7, the flue is thin-walled components, in handling and installation should be gently handle, not to impact, not in the pipeline to pile other heavy objects and walking.8, the roof flue should be in the roof insulation layer, fire layer before construction.9, the use of gas water heater exhaust system is strictly prohibited.

Send your message to us

CHECK VALVE LIFT TYPE DUCTILE IRON DIN DN15- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords