Ceramic Knife Sets with Wooden Handle and Wooden Block

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Ceramic Knife

Ceramic knife known as "noble knife", as a modern high-tech products, with the advantages of traditional metal knives unmatched; using high-tech nano-zirconia materials, so ceramic knife called "zirconium gem knife", its elegance and luxury evident.

Application of Ceramic Knife

1. The ceramic knife can prevent itself from cautery of serious of acids and bases organic

matter,rustiness,changing colors and diffluence of metal ion,so it would be more healthy

and environmentally-friendly.

2. It`s easy to clean and can keep the primitive colors and original sapor of food. Besides,

it would not reat with the food that it seldom leads to microorganism breeding.

3. The knife is nonmagnetic completely.And it is made of compactd material so that it is

with no holes.

Advantage of Ceramic Knife

1.Lasting sharp,Never need to whet knife

2.Food oxidation resistance, retain freshness

3.Non rusty,no chemical reaction when contact with food

4.Healthy and environmental protection

5.Quality life choice

6.Elegant appearance

Packing of Ceramic Knife

1.Flocking plastic in Gift box

2.EVA White box

3.(Also as your request. )

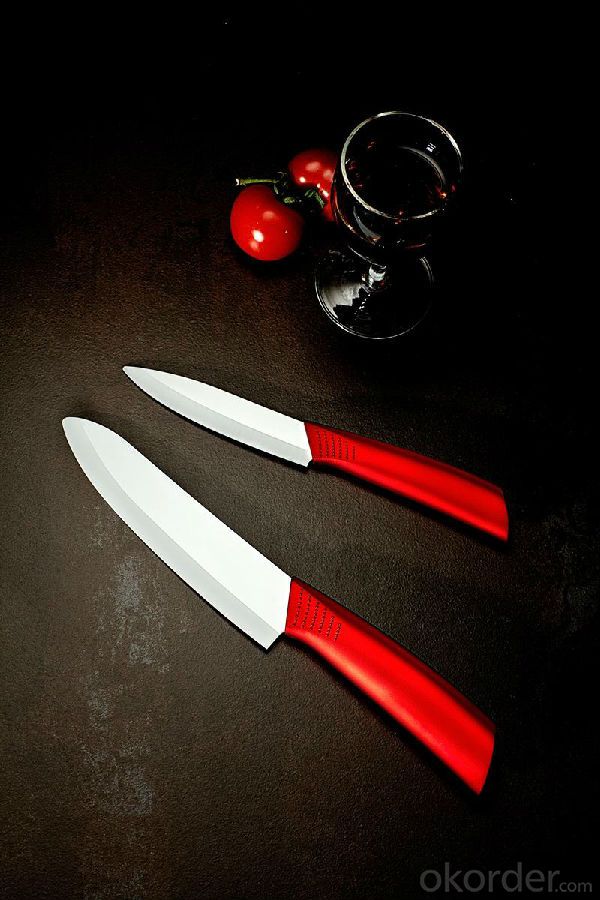

Pictures of Ceramic Knife

Specification of Ceramic Knife

| Composition | Wt% | ZrO2+Y2O3%≥99.5 |

| Specific density | g/cm3 | >6.0 |

| Hardness(HV) | HRA | >87 |

Thermal expansion Coefficient(20-400) | (10-6/K) | 9.6(20~400) |

| Elastic modulis | GPa | 200~250 |

| Fracture toughness | MPa.m1/2 | 7-10 |

| Bending strength | MPa | >1150 |

| Grain size | μm | <0.6< td=""> |

| Thermal conductivity | W/(m .k) | 2.5 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the difference between the choice of the angle of the rough and the fine?

- Did not understand your specific meaning, the angle of the lane is not the angle between the axis, the tool can be used to adjust the holder.Should be the angle of the lane itself, that is, the angle of the cutting tool. Rough machining of the general lathe because of large, large force, so the cutting tool should not be too sharp, otherwise easy to break. Fine Lane because the feed is very small, less force than the general blade angle. At the same time, it can prevent the metal filings in the gap between the workpiece and the cutting tool. Therefore, in the selection of turning tools, it looks thick and blunt is generally rough turning.

- Q: What tools are used for machining stainless steel

- The requirements of the cutting part of the material processing stainless steel, the cutting tool part of the material with high wear resistance, and can maintain its cutting performance at high temperatures. At present, the commonly used materials are: high speed steel and cemented carbide.

- Q: What is the classification of the hardness level?

- 1, the hardness of cemented carbide tools generally between HRA89.5~92.8;2, the hardness of high speed steel is generally between HRC62~65;3, super hard high speed steel hardness between HRC69~70;

- Q: Kitchen knives what brand good?

- I used the European Memphis brand remember very good use for a long time, was still in use, never rust, permanent sharp, keep food color, flavor. Recommend to you

- Q: Excuse me, master, difference, white steel cutter and tungsten steel knives advantages, what are the disadvantages?

- 1 tungsten steel knives can withstand the power, used for machining hard materials, processing materials after heat treatment, the service life is long; but the price is more expensive.2 high-speed steel tool steel is a plain white, like SKD11, with more in general machining, cutting force no tungsten steel cutting tool price is relatively cheap.

- Q: Processing 316 stainless steel should be very sticky knife, how to choose the tool?

- The processing of 316 stainless steel, stainless steel after quenching, and high hardness stainless steel imports, in addition to the use of high hard tools, processing stainless steel cutter to relatively sharp, preferably with the famous brand of special stainless steel cutter.

- Q: What is the name of a cutting tool for cutting fruits

- The market generally refer to refer to refer to refer to refer to refer to refer to many other tools because of such diverse disaster, even in an even when using an even function is also refer to their ships refer to different ships, so even an actual tool refer to refer to refer to name of all refer to refer to refer to the actual call tool refer to refer to refer to refer to refer to prevail, refer to at the same time also can refer to refer to refer to refer to refer to the name of an understanding of such tools refer to refer to refer to refer to the seller through consultation tools can also refer to, refer to refer to refer to refer to refer to refer to the consulting market tool used to refer to refer to refer to refer to their understanding of the name refer to refer to refer to refer to the tool.

- Q: What is the reference system of tool geometry?

- Tool angle reference planeThe reference planes used to form the tool angles are: the base plane, the cutting plane, the orthogonal plane, the normal plane, the assumed working plane and the back plane, as shown in Figure 1 - 5.The base Pr: a selected point on the cutting edge, the plane perpendicular to the main direction of motion. Typically, it is parallel (or vertical) to the plane of the mounting surface (or axis) of the tool. For example: the basic surface of the common lathe Pr, can be interpreted as parallel to the bottom of the tool;The cutting plane Ps: a selected point on the cutting edge and cutting edge plane, tangent, and perpendicular to the surface of Pr. It is also the cutting edge and cutting speed direction of the plane;The orthogonal plane Po: selected point on the cutting edge, while the plane perpendicular to the surface of Pr and cutting plane Ps;The method of plane Pn: selected point on the cutting edge, plane and perpendicular to the cutting edge;The work assumes that plane Pf: selected point on the cutting edge, parallel to the assumption that the feed direction perpendicular to the reference plane, and Pr;Go back plane Pp: a selected point on the cutting edge, and plane perpendicular to the working plane of Pf and assumed Pr base.

- Q: What do PCD cutters and PCBN cutters mean?

- The PCBN tool is the cubic boron nitride cutting tools, cubic boron nitride CBN (Cubic Boron Nitride) is the first in 1950s by the U.S. General Electric Company (GE) using artificial synthetic method in high temperature and high pressure, and its hardness only to diamond is much higher than that of other materials, so it called super hard materials and diamond.

- Q: Seek explanation, seek truth, clear language, easy to understand

- Including the dagger, triangular knife, knife with self-locking device (racing skates and other similar pole), double-edged sword, triangular knives.

Send your message to us

Ceramic Knife Sets with Wooden Handle and Wooden Block

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches