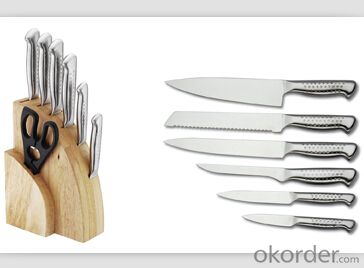

Knife,stainless steel knife for kitchen use

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Set includes:

1 × chef knife

1 × bread knife

1 × carving knife

1 × utility knife

1 × paring knife

High-carbon stainless steel blade holds a superior sharp edge

High quality stainless steel,tool vertical tough strong corrosion resistance

Comfortable grip handle for balance and control

Many other designs are available

Customized orders are accepted

Features:

No slot foldable magnetic wooden knife block

Seamless welding technique

Fashionable and comfortable handle design

Multifunction kitchen knife set meets customer's needs during cooking

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Electronic Link

Experienced Staff Form A

Green Product Guarantee/Warranty

International Approvals Packaging

Price Product Features

Product Performance Quality Approvals

Reputation Service

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: Cutting tool materials

- Other tool materials:(1) ceramic cutting tool: a kind of cutting tool made of alumina (Al2O3) or silicon nitride (Si3N4) as matrix, and then adding a small amount of metal at high temperature.(2): artificial diamond is an allotrope of carbon, is currently the most hard tool materials, the micro hardness is 10000HV.

- Q: Open teeth is how one thing, the specific operation process.

- Open? It is wateredAfter the general tool blank out need grinding edge, look at what you have in front of the cutter, angle, mainly to prevent the cutting tool when there is a collision, but also to sharp, generally open the sharp angle better, but life is relatively short, 5-10 degree can be looked at to. The

- Q: Kitchen knives what brand good?

- Yangjiang eighteen sons, cost-effective.

- Q: Processing 316 stainless steel should be very sticky knife, how to choose the tool?

- We used to use ceramic cutter head, alloy knife head is easy to stick knife

- Q: How to select NC milling cutter

- In the free surface (die) processing, because the end of the cutting speed of ball end cutters is zero, so as to ensure the machining accuracy, cutting the apex densely spaced generally distance, therefore ball commonly used in curved surface machining. The flat tool has better surface quality and cutting efficiency of ball cutter, therefore, as long as the guarantee but cut under the premise of both surface rough machining precision machining, should be preferred flat knife. In addition, the tool life and the relationship between the price of great accuracy and tool, must pay attention to is, in most cases, choose a good tool while increasing the tool cost, but the processing quality and efficiency of the improved, can make the whole process cost is reduced greatly.

- Q: I know that there are two numbered Rules, one of which is T0101, T0202, T0303, T0404, etc.There is a T0101, T0102, T0103, T0104, such as the number, under the advice of the two numbersCan it be mixed? If you can, how to determine the knife mark?

- Can be made in accordance with the knife type and feed direction

- Q: PM rough machining, how to make the tool from the rough external introduction?

- I still do not understand, I did not set the rough boundary, but the knife or go straight down. Why do I set down the road very oblique knife out of depressed, today the initial processing broken two knives

- Q: What are the factors that affect the tool life

- The material of the workpiece being machined.Better thermal conductivity of the workpiece material, by cutting away from the workpiece and by more heat, more conducive to reduce the cutting zone temperature, reduce wear of the tool workpiece; the hardness and strength of the material is high, the cutting force is greater, the greater the power consumption, the cutting temperature is higher, so that the tool wear.

- Q: Woodworking engraving machine commonly used tools which?

- Flat knife, also known as the column knife, mainly rely on the side edge of the carving, the bottom of the blade is mainly used for plane repair. The end face of the column cutter is larger, and the carving efficiency is high. The utility model is mainly used for the contour cutting, the milling plane, the area rough carving, the curved surface rough carving and so on.The ball end cutter, the cutting edge of the knife is a circular arc, forming a hemisphere in carving wood engraving machine engraving process process, uniform stress, smooth cutting. Therefore, the utility model is especially suitable for curved surface carving, and is used for surface semi fine carving and surface fine carving. Not suitable for milling knife.Bovine nose knife, knife knife and knife is a mixture of column, it has the characteristics of spherical hand carving surface, has the characteristics of column knife on the other hand, can be used for milling.Taper flat knife. The most widely used in the engraving industry. Bottom edge, bevel knife known as tip, similar to the column knife, can be used for finishing a small flat, tilted side edged knife cone, the formation of sloping sides in the process of carving. The characteristics of the knife in the structure can make it possible to achieve a unique three-dimensional carving industry angle effect. The taper cutter is mainly used for single line engraving, rough carving, fine carving, 3D clear angle, projection carving, image gray carving and so on.

- Q: Why can't we use diamond tools to process iron materials?

- General black metal mainly including iron and steel, both carbon and these materials exist, can be said that the black metal is pro carbon material, diamond composition is carbon, with diamond tool in machining iron-based materials, diamond surface carbon and easy cutting, cutting surface adhesion occurs, leading to the tool is not sharp, by processing the temperature rise, the temperature is high, and oxygen in the air to exist, the diamond is prone to macro elements carbonization and graphitization of diamond. This is why diamond tools are generally not processing of ferrous metal materials.

Send your message to us

Knife,stainless steel knife for kitchen use

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords