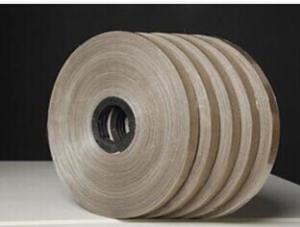

Raw Materials for Refractory Ceramic Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

ceramic fiber tape

ceramic fiber tape with stainless steel wire

size:2~3.0mm

width:25~100mm

temperature:800~1000C

ceramic fiber tape

ceramic fiber tape with stainless steel wire

size :2.0mm-3.0mm

width:25mm-100mm

refractoriness:800--1000C

introduction

It is used as heat insulating materrials and an excellent substitute for asbestos tape

it is a new type thermal insulation fireproofing material has light weight, small thermal conductivity,good performance of thermal insulation ,steady physical and chemical performance.

Used in petroleum,chemicals,metallurgy,electric power etc manufacture industry.

APPLICATIONS:

furnace curtains

thermostability

fireproof, refractory

high temperature electrical insulation

Under the environment of high temperature of protective clothing, gloves, wigs, helmet, boots, etc

FACTORY:

- Q: What are the fire protection standards of insulation materials?

- The combustion performance of thermal insulation materials for exterior walls of all civil buildings, within the scope of fire design auditing and fire control acceptance, should be brought into the auditing and acceptance. As for the "Management Regulations on Supervisions of Fire Prevention and Control for Building Projects" (Ministry of Public Order No. 106) , all civil buildings which are out of the scope of Article 13 and 14 are included in the random check. Before the release of new standard, it must be strictly implemented the Article II of the "Fire prevention Interim Provisions on civil external wall insulation system and external wall decorative" ([2009] No. 46), namely, the insulation materials of civil buildings must use materials with A-level combustion performance.

- Q: What is the best refractory company?

- Chinese brick trading network, is the most authoritative third party service platform, brought together more than 3000 refractory enterprises, working day experts online to answer, to analyze and evaluate the refractory industry, at the same time, cooperation with some refractories Association, I hope to help you!

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: What is the requirement of refractory concrete for raw materials? What is the main principle of commercial mixing station?

- Commodity concrete stations can not be produced in general, and are made by professional fire resistant concrete manufacturers.

- Q: About the market issues of thermal insulation material and refractory material.

- In fact, the thermal insulation material produced by the Sichuan-Benniao Hing construction company is very good, you can get the company's information just by inputing the Sichuan-Benniao Hing construction company into Baidu

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: Can I use ordinary cement with the addition of sand, clay, and salt as refractory material to paste the stove?

- Add some hair and slags, or it will crack before calcination.

- Q: What kind of refractory materials can withstand 1500℃ when processing briquette stove core and meanwhile cost less?

- Alkali resistant castables cost the least.

- Q: who knows the fire resistant level of fireproof gypsum board ?

- Gypsum board is flame retardant materials, combustion performance rating B1, but when mounted on a steel joist, it can be seen as rating A(non-combustible material) . So it is fine to use as a ceiling. As for the Dragon brand, rock wool can be filled in the mddle according to its design requirements, using different series of gypsum board, steel stud. the walls may have fire resistance and sound insulation property of various degrees. You can randomly choose several samples to run some tests at the quality inspection insititute and the quality of these samples are subject to the testing results.

- Q: who knows the fire endurance of fireproof coating?

- fireproof coating of different thickness differs in its fire endurance. Let me intrduce you as follows: The amount of time of 0.5 hours refractory thickness 0.45mm 0.79kg / m21 hr 0.9 mm 1.5kg / m21.5 hour 1.4 mm 2.3kg / m22 hr 2.0 mm 3.3kg / m22.5 h 2.8 mm 4.6 kg / m2

Send your message to us

Raw Materials for Refractory Ceramic Fiber Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords