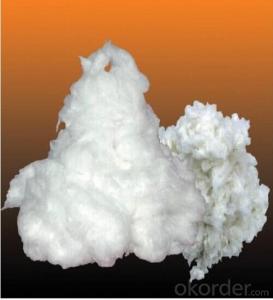

Raw Materials for Refractory:Insulation Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1)Asbestos free

2)Resistance to high temperature and chemical erosion

3)High mechanical strength

4)Low thermal conductivity

1260 Insulation Ceramic Fiber Bulk for Sale

1)Ceramic fiber bulk is made of coal gangue by melting at high temperature through resistance furnace, before being blown or spun into fiber.

As a neutral and acidic material, except reaction with the strong acid-alkali, ceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity,also lightweight,heat insulation,low thermal conductivity etc.

2)Specifications

1.STD 1260 Ceramic Fiber Bulk

2.HP 1260 Ceramic Fiber Bulk

3.HA 1360 Ceramic Fiber Bulk

4.HZ 1430 Ceramic Fiber Bulk

3)Application:

(1)Raw material for fiber blanket, board products; Raw material for fiber textile products;

(2) Joint sealing and filling insulation for industrial kilns and fuming channel and high temperature pipes

(3) Raw material wet processed products;

(4) Fiber spraying;

(5) Raw material for coatings and castables

(6) Insulation fillings for corner and complex space.

Technical data

ITEM | Standard | Prue | High Aluminum | Zirconium | ||

Classification temperature(℃) | 1260 | 1260 | 1360 | 1430 | ||

Work temperature(℃) | 1050 | 1100 | 1200 | 1350 | ||

Color | white | white | white | white | ||

Fiber Diamond (um) | Blowing | 2-4 | 2-4 | 2-4 | 2-4 | |

| Swinging | 3-5 | 3-5 | 3-5 | 3-5 | |

Chemical Composition(%) | AL2O3 | 46 | 47-49 | 52-55 | 39-40 | |

| AL2O3+ SIO3 | 97 | 99 | 99 | - | |

| AL2O3+ SIO3+ ZrO2 | - | - | - | 99 | |

| ZrO2 | - | - | - | 15-17 | |

| Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+ K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |

1)Asbestos free

2)Resistance to high temperature and chemical erosion

3)High mechanical strength

4)Low thermal conductivity

5)Low thermal storage

6)Resistance to heat-shock

7)Easy installation

- Q: Preparation of refractory clay

- Is it to make refractories? Add some andalusite to the refractory mortar will improve the effect.

- Q: What is streaming fireproof material?

- Streaming fireproof material is castable refractory that can flow and degas without virbration, which is suitable for thin-wall or places that cannot be molded by vibration because of complex shapes. Well, appropriate amount of water is necessary for it. Its characteristic goes that it can be cast into various shapes of construction body without virbration and it will not reduce or not significantly reduce the performance of castable at the same time.

- Q: What are the characteristics of thealuminium oxide refractory?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: What's the poured refractory material?

- According to the volume density, it can be classified as follows: Heavy (>2.0g /cm3), medium heavy (1.0-2.0g/cm3), light (0.4-1.0g/cm3); classified by binding agent: hydraulic bond, chemical bond, coagulation binder, hydraulic and coagulation binder; classified by material: material of clayey, high alumina, silicious, magnesian, alumina-magnesia, magnesian-chrome, magnesia-zirconia, silicon carbide-based, etc.

- Q: Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q: Which brand of AAA refractory is good?

- Rong Sheng Kerui quality refractory Zhengyuan Shenzhou Saatchi these brands are very good, with high refractoriness, durability and with a good cost performance. Get the majority of customers' recognition.

- Q: Does anyone know what is the use of waste refractory materials?

- Waste refractory materials can be 1, Recycled to do the aggregate and powder of castable , or make bricks. 2, can be reused after smash.3, Metal silicon is an anti oxidant in refractory material, mainly functioning as he oxidation resistance, at the same time improve its toughness.

- Q: What is neutral refractory? Can refractory suppliers tell the main components of it?

- // Baike? Url x3d CQ3i6_yUCWUMgk3aaRGGLURNtvKPl5IdZpj35Yvommk7Nyif0IJD-SkdIW29GCHwLpb9cT9Ii25GLcEJg-ZHcq "target x3d" _blank "x26gt; http://baike.baidu.baidu.

- Q: How many external wall thermal insulation fireproof material are there

- Class A exterior wall insulation: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic foam, foam glass

- Q: Who knows about the B-level fireproof insulation materials?

- Organics, extruded sheet, polyphenyl board and phenolic resin. The fireproof?performance of sea capacity module (fireproof and thermal insulation material) is B1-level with the heat conductivity coefficient of only 0.028w / m · k. It is a good choice. A-level: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic aldehyde, and foam glass. B-level: Rubber and plastic, extrusion molding, polyphenyl, PEF.

Send your message to us

Raw Materials for Refractory:Insulation Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords