Ceramic Fiber Paper 2300℉ Standard Roll for Fireproof Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper

CMAX ceramic fiber paper is manufactured from selected high purity ceramic fibers with low shot content. Its organic binders provide the product with good strength against tearing. Ceramic fiber paper is excellent for heat seal.

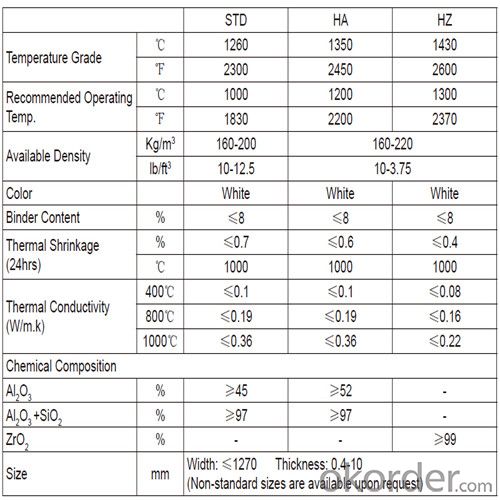

Ceramic fiber paper is available in two classified temperatures: STD 1260℃ and HA 1350℃

Feature of Ceramic Fiber Paper

Withstand high temperature

Low thermal conductivity

Less heat storage

Resistance to thermal shock

Stabilized to most chemical

Corrosion resistance

Not easily torn

Absorb sound

Even density and thickness

Easy to install

Application of Ceramic Fiber Paper

High temperature gasket

Boiler door seal

Refractory expansion joint

Furnace backup insulation

Lining for aluminum casting molds

Thermal and electrical insulation for heaters

Acoustic and thermal insulation for automobile mufflers

Heat insulation for exhaust tubes and pipes

Electrical switch box fire protection

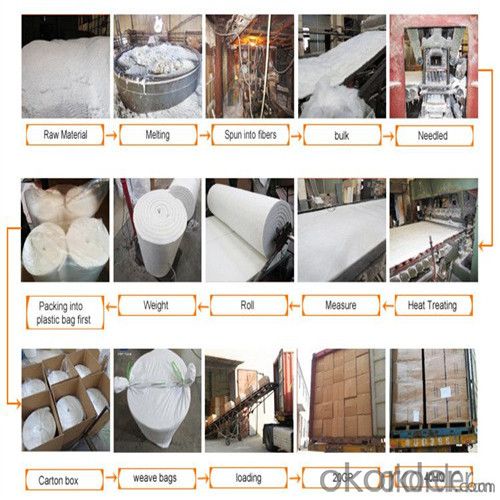

Image of Ceramic Fiber Paper

Technical Data of Ceramic Fiber Paper

Who We Are

l OKorder is offering high quality Ceramic Fiber Paper at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over.

l OKorder annually supplies a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- I used to work in the ceramic fiber factory for two years, and the main contact was fiber. There is not much contact with paper products and so is the understanding of fiber paper.The use of heat insulation material can not be considered temperature, as well as environmental, economic, atmosphere and many other factors to consider.

- Q: Is the slag ball of the ceramic fiber useful?

- There's not much use value, the only effect is recycled to reduce waste, prevent pollution two.

- Q: Ceramic fiber spray and thrown silk floss, which is better?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);4, HLGX ceramic fiber board, carpet, light heat insulation castable application: blowing short cotton fibers, fine low thermal conductivity is more suitable for dispersed, as ceramic fiber paper, ceramic fiber board and Castable Ceramic Fiber Wet products.

- Q: How are ceramic fiber papers attached to the interior wall?

- Ceramic fiber paper afraid of water, and no adhesion, putty powder is difficult to hang, it is almost impossible to wallpaper, ceramic fiber paper with ceramic fiber mortar by vacuum filtration process, the surface will remain part of the fiber powder, suggest that you make ceramic fiber paper on the walls of the inner layer. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter.

- Q: Where is the best packing area for ceramic fibers?

- Compared with asbestos textiles, ceramic fiber textiles have the following advantages:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) ceramic fiber cloth, band, packing and other products with non alkali glass fiber yarn as strengthening material have higher insulation and high temperature electrical insulation than glass fiber.5) non-toxic, harmless and odorless.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. Ceramic fiber products (aluminum silicate fiber products) the ceramic fiber products (aluminum silicate fiber products) products: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range 871 to 1427 DEG C, under special circumstances can be short-term in the limit of high temperature above the use.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

- Q: What's the function of refractory ceramic fiber band?

- Ceramic fiber belt main uses: industrial heat insulation, pipe and cable insulation coating, exhaust pipe insulation coating, flange connection, heat radiation shielding, high temperature furnace door curtain, etc..

Send your message to us

Ceramic Fiber Paper 2300℉ Standard Roll for Fireproof Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords