Ceramic Fiber Paper - Thermal Shock Resilient Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Shock Resistant Ceramic Fiber Paper

Product Description:

Ceramic fiber paper is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber yarn is also different, and they are suitable for different working temperatures.

Ceramic fiber yarn can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Specifications:

Al Content (%): 32-55

Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

Density: 64-160kg/m³

Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Product Packing:

Plastic bag in a carton box

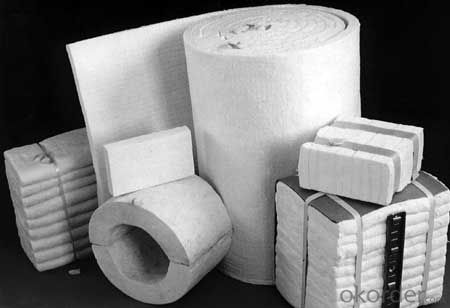

Product Images:

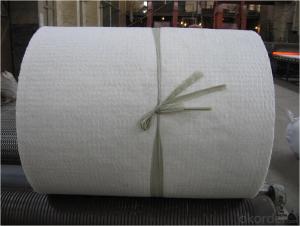

◆Packaging

◆Product Process

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton.Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- I used to work in the ceramic fiber factory for two years, and the main contact was fiber. There is not much contact with paper products and so is the understanding of fiber paper.The use of heat insulation material can not be considered temperature, as well as environmental, economic, atmosphere and many other factors to consider.

- Q: Is the slag ball of the ceramic fiber useful?

- According to the technical staff of Ji'nan Huolong thermal ceramics limited liability company, their company production of ceramic fiber paper and ceramic fiber board using slag ball dregs is removed, usually as raw materials into a new round of melting silk is melted again.

- Q: The condition of ceramic glass fiber at high temperature

- Glass and ceramic fibers are inorganic non-metallic materials, they are silicate, can be used as structural materials that emphasize mechanical properties, but also can be used as functional materials that emphasize photoacoustic magnetic properties, but the 1. general glass is amorphous substance, the fibers are formed by melting under drawing while; ceramics is a crystal structure of the fiber by solution or melt into the crystal growth out of course, can also be formed by chemical synthesis or decomposition method;

- Q: Do ceramic fiber paper smell at high temperature?

- Ceramic fiber paper is made from high purity ceramic fibers, with a small amount of scientifically selected and tightly controlled binders, and binders will evaporate during use. If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Aluminum silicate blanket is used for heat preservation tube or aluminium silicate ceramic fiber paper

- The stomatal density can know, aluminum silicate fiber blanket rate is much higher than that of aluminium silicate ceramic fiber paper, because the aluminum silicate fiber blanket belongs to pure inorganic products, and the pipe wall fits more closely, so the aluminum silicate fiber blanket thermal insulation on the pipeline used in large quantity, because the aluminum silicate ceramic fiber paper with organic ingredients, better insulation aluminum silicate fiber blanket. If you have a large number of pipes to do heat preservation, you can refer to the following fire pipe insulation thickness selection experience table.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency.

- Q: What can I do to get the clothes off the ceramic fiber?

- Remove pen marks from clothes easilyFirst of all, the alcohol evenly sprinkled on the pen printed on the pen, alcohol should be used at a concentration of not less than 75% of the alcohol used in medicine. Remember to put on this side of the garment that has been poured down. Do not touch other surfaces of the garment. Otherwise, the color of the pen may be stained with other parts of the garment.Prepare most of the water, and then pour two full bottle of bleach water in the water, stirring, and a little washing powder, so that the laundry powder can be fully dissolved in water. Soak your clothes completely in water for twenty minutes. Washing clothes, there is no mark!Clothes stained with pens, ball pen marks, there is another way to solve: that is, do not rush to the clothes into the water, but first wash with gasoline, washed parts of the re wash.

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q: What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

Send your message to us

Ceramic Fiber Paper - Thermal Shock Resilient Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords