Ceramic Fiber Paper 1430 Hz

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls kg

- Supply Capability:

- 1000 Rolls Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper 1430 HZ

Thermax ceramic fiber paper 1430 HZ is made of selected high purity ceramic fibers with low shot content. ceramic fiber papers 1430 HZ are used to solve a wide variety of heat-related problems. Its organic binders provide the product with good strength against tearing.

The ceramic fiber paper 1430 HZ can well used in the 1350oC working tempreture.

Feature of Ceramic Fiber Paper 1430 HZ

Stabilized to most chemical

Corrosion resistance

Not easily torn

Absorb sound

Even density and thickness

Easy to install

Withstand high temperature

Low thermal conductivity

Less heat storage

Resistance to thermal shock

Application of Ceramic Fiber Paper 1430 HZ

Thermal and electrical insulation for heaters

Acoustic and thermal insulation for automobile mufflers

Heat insulation for exhaust tubes and pipes

Electrical switch box fire protection

High temperature gasket

Boiler door seal

Refractory expansion joint

Furnace backup insulation

Lining for aluminum casting molds

Packing and Delivery

The ceramic fiber paper 1430 HZ will be put into the plastic bag then into carton box.

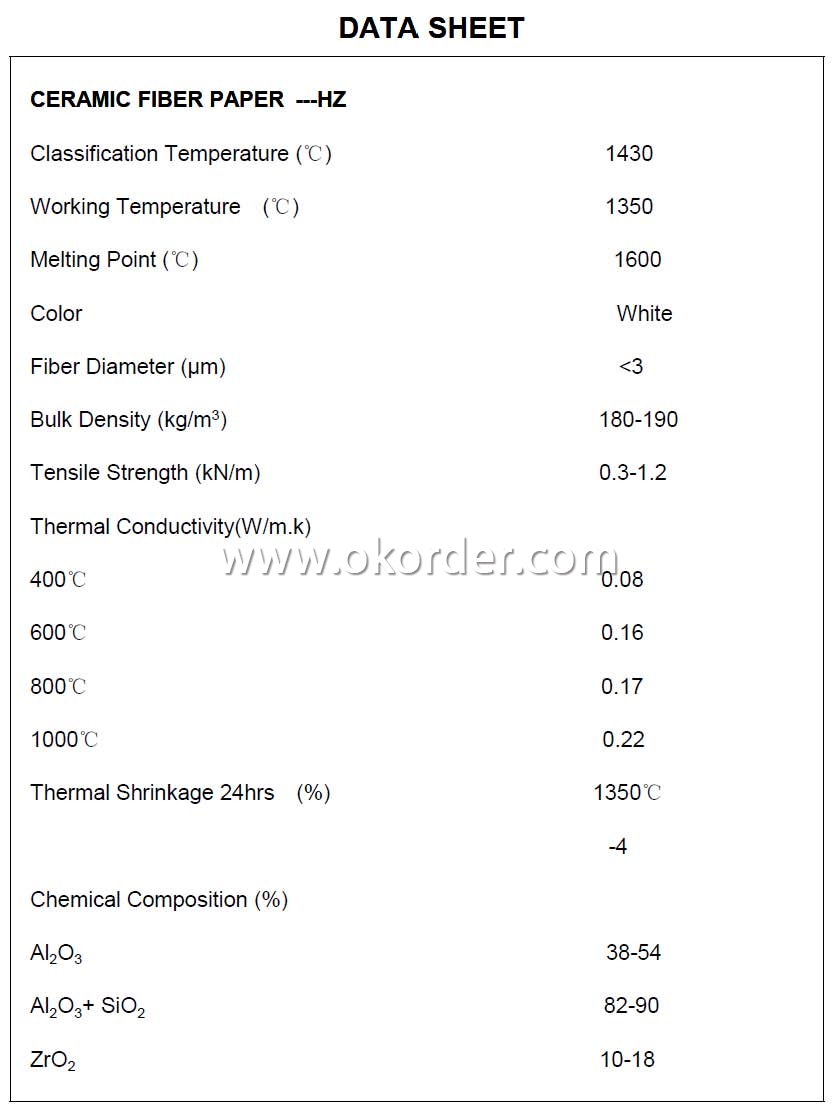

Technical Data of Ceramic Fiber Paper 1430 HZ

- Q: Are ceramic fiber paper permeable?

- However, in the case of water can not play a good insulation effect, but the use of ceramic fiber paper temperature is about 1000 degrees, there will be no water, Ji'nan Sheng Yang ceramic fiber manufacturers

- Q: Ceramic fiber insulation moisture-proof, but also play a cooling effect?

- Fiber cotton can be further processed into fiber blanket, board, paper, cloth, rope and other products.Ceramic fiber is an efficient insulation material, with light weight, high strength, low oxidation resistance, low thermal conductivity, good flexibility, corrosion resistance, low heat capacity and sound insulation and so on.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q: Is everybody ceramic fiber cotton poisonous?

- The main danger of ceramic fiber is easy weathering, easy to produce fiber cotton dust, penetrating power, easy to be inhaled, easy to adhere to the lungs, not easy to exhaust, causing lung disease, and even induce cancer! Highly hazardous, has been listed as a high concern products Europe

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- But the use of different temperature, nano microporous insulation materials used in 1000 DEG, 1600 DEG C high temperature resistant ceramic fiber.

- Q: What are the features of ceramic fiber gaskets?

- 1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Stick on the plate for what you see over the place, or if used in high temperature place, we recommend a special high temperature fireproof glue;

- Q: What fiber glass made of ceramic fiber paper?

- The raw material of the ceramic fiber paper is the ceramic fiber cotton as the basic raw material, and the unique injection process cotton is preferred.

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- Aluminum alloy advantages: air oxidation resistance, cost-effective, easy to manufacture. The disadvantage is that the elasticity is poor and the strength is low.

- Q: What's the function of refractory ceramic fiber band?

- Ceramic fiber belt main uses: industrial heat insulation, pipe and cable insulation coating, exhaust pipe insulation coating, flange connection, heat radiation shielding, high temperature furnace door curtain, etc..

Send your message to us

Ceramic Fiber Paper 1430 Hz

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls kg

- Supply Capability:

- 1000 Rolls Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords