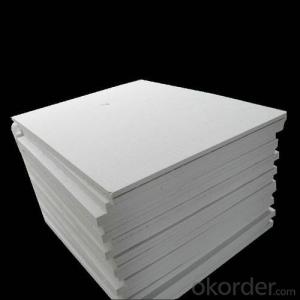

Low Thermal Conductivity Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1.Easy to wrap, shape or cut

2.Lightweight

3.Low thermal conductivity; Low heat storage

4.Good uniformity and smooth appearance

5.Good flexibility and toughness and resistance to avulsion

6.Good dielectric strength and sound insulation

7.Excellent thermal shock resistance

8.Excellent chemical satability and machining property

9.Excellent corrosion resistance

Applications

1.Die cut gaskets between castings in coke oven doors, blast furnace hot air piping, aluminium heat treating furnace, tuyeres and heat treat furnaces.

2.Backup for brick and monolithic refractories in blast furnace stoves, piping, tundish, ladle, hot metal cars, trough etc.

3.Mould wrapping for controlled cooling

4.SEN isulation wraping

5.Shield for welding & brazing operation

6.Rotary klin back-up insulation

7.Fabricated into tapout cones for Aluminium industry.

8.Strips in bottom of ingot mould for sealing

9.Expansion joint packing

10.Induction coil liner

11.Mould liner

12.Silencer interleaf

13.Ladle & tundish insulation

14.Asbestos paper replacement

15.Hot top linings

16.Thermal and electrical insulation

- Q: Are ceramic fiber paper permeable?

- Ceramic fiber paper is said to be paper, in fact, is relatively large density, but still cotton like, it is permeableCeramic fiber composite board is able to play a certain waterproof effect

- Q: Is the slag ball of the ceramic fiber useful?

- According to the technical staff of Ji'nan Huolong thermal ceramics limited liability company, their company production of ceramic fiber paper and ceramic fiber board using slag ball dregs is removed, usually as raw materials into a new round of melting silk is melted again.

- Q: What are the materials for making ceramic fibers?

- In recent years, because of the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been more and more widely used in the domestic Chinese, development prospect is very promising. Throw carpet and spray carpet difference

- Q: The condition of ceramic glass fiber at high temperature

- This can only say that in general, but there are special circumstances, such as carbon fiber as a special case of ceramic fiber, it can form a fabric, its wide range of applications, from high temperature refractory materials, friction materials, insulation materials, structure of rocket radar stealthy materials to civilian fishing have its place to display.

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- But the use of different temperature, nano microporous insulation materials used in 1000 DEG, 1600 DEG C high temperature resistant ceramic fiber.

- Q: Ceramic fiber spray and thrown silk floss, which is better?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);4, HLGX ceramic fiber board, carpet, light heat insulation castable application: blowing short cotton fibers, fine low thermal conductivity is more suitable for dispersed, as ceramic fiber paper, ceramic fiber board and Castable Ceramic Fiber Wet products.

- Q: Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- Ceramic fiber paper is made from high purity refractory fiber and used in high temperature insulation.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- Aluminum alloy advantages: air oxidation resistance, cost-effective, easy to manufacture. The disadvantage is that the elasticity is poor and the strength is low.

- Q: Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- Tianjin solid composite reflective insulation board, he has one of the biggest advantages of long-term high temperature, the use of chemical stability, and can be used for a long time.

Send your message to us

Low Thermal Conductivity Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords