Ceramic Fiber Paper for High Temperature Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper

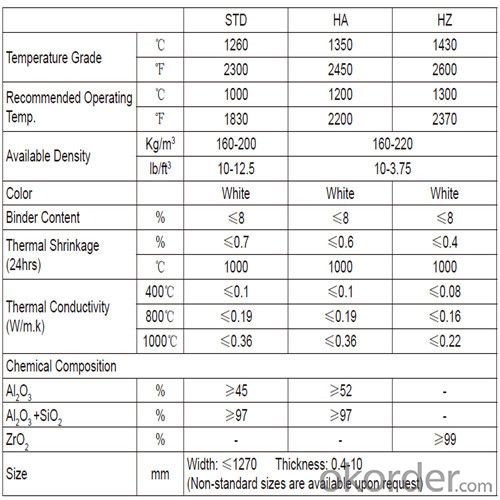

CMAX ceramic fiber paper is manufactured from selected high purity ceramic fibers with low shot content. Its organic binders provide the product with good strength against tearing. Ceramic fiber paper is excellent for heat seal.

Ceramic fiber paper is available in two classified temperatures: STD 1260℃ and HA 1350℃

Feature of Ceramic Fiber Paper

Withstand high temperature

Low thermal conductivity

Less heat storage

Image of Ceramic Fiber Paper

Technical Data of Ceramic Fiber Paper

Application of Ceramic Fiber Paper

High temperature gasket

FAQ

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What are the materials for making ceramic fibers?

- Ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity and heat resistance of small and mechanical shock and other interests, so in the machinery, metallurgy and chemical industry, petroleum, ceramics, glass, electronics etc. have been widely used.

- Q: The condition of ceramic glass fiber at high temperature

- This can only say that in general, but there are special circumstances, such as carbon fiber as a special case of ceramic fiber, it can form a fabric, its wide range of applications, from high temperature refractory materials, friction materials, insulation materials, structure of rocket radar stealthy materials to civilian fishing have its place to display.

- Q: Ceramic fiber spray and thrown silk floss, which is better?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);4, HLGX ceramic fiber board, carpet, light heat insulation castable application: blowing short cotton fibers, fine low thermal conductivity is more suitable for dispersed, as ceramic fiber paper, ceramic fiber board and Castable Ceramic Fiber Wet products.

- Q: How are ceramic fiber papers attached to the interior wall?

- Ceramic fiber paper afraid of water, and no adhesion, putty powder is difficult to hang, it is almost impossible to wallpaper, ceramic fiber paper with ceramic fiber mortar by vacuum filtration process, the surface will remain part of the fiber powder, suggest that you make ceramic fiber paper on the walls of the inner layer. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter.

- Q: Do ceramic fiber paper smell at high temperature?

- If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Where is the best packing area for ceramic fibers?

- Compared with asbestos textiles, ceramic fiber textiles have the following advantages:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) ceramic fiber cloth, band, packing and other products with non alkali glass fiber yarn as strengthening material have higher insulation and high temperature electrical insulation than glass fiber.5) non-toxic, harmless and odorless.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency.

- Q: What can I do to get the clothes off the ceramic fiber?

- Remove pen marks from clothes easilyFirst of all, the alcohol evenly sprinkled on the pen printed on the pen, alcohol should be used at a concentration of not less than 75% of the alcohol used in medicine. Remember to put on this side of the garment that has been poured down. Do not touch other surfaces of the garment. Otherwise, the color of the pen may be stained with other parts of the garment.Prepare most of the water, and then pour two full bottle of bleach water in the water, stirring, and a little washing powder, so that the laundry powder can be fully dissolved in water. Soak your clothes completely in water for twenty minutes. Washing clothes, there is no mark!Clothes stained with pens, ball pen marks, there is another way to solve: that is, do not rush to the clothes into the water, but first wash with gasoline, washed parts of the re wash.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Not used in high temperature industry, then with double-sided adhesive can be.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket?

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

Send your message to us

Ceramic Fiber Paper for High Temperature Applications

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords