Ceramic Fiber Module for Boiler Insulation - Refractory Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief description

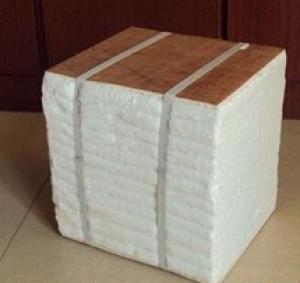

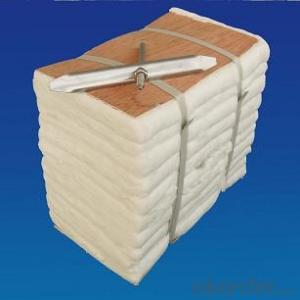

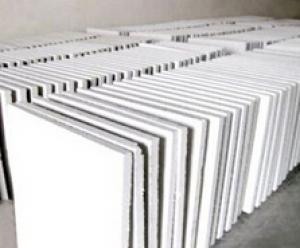

Ceramic fiber module, also called aluminum silicate fiber module, is a ceramic raw material coal gangue, after calcining, grinding, after electrify high temperature melt into liquid, with roller thrown into ceramic fiber cotton and further processed into ceramic fiber module. On the basis of the characteristics of ceramic materials, ceramic fiber module is fireproof, heat preservation, heat insulation, sound-absorbing, energy-saving features, widely used in petroleum chemical metallurgical machinery building materials and other industries.

Main Technical Property Indexes

Item | SYGX-289 | SYGX-389 | SYGX-489 | |

AL2O3 % | ≥45 | ≥45 | 52-55 | |

AL2O3+SIO2 | ≥97 | ≥99 | ≥99 | |

Fe2O3 % | ≤1.0 | ≤0.2 | ≤0.2 | |

Density(kg/m3): | 220±10 | |||

Maximum temperature (°C) | 1260°C | 1400°C | ||

Thermal conductivityW/m.k ≤ | 200°C | 0.045-0.060 | ||

400°C | 0.095-0.120 | |||

600°C | 0.160-0.195 | |||

Heat the permanent linear change(%) | 1000°Cx24h≤-3 | 1100°Cx24h≤-3 | 1200°Cx24h≤-3 | |

Typical Application

Ceramic fiber module can directly fixed on the industrial kiln furnace shell steel anchor nail, has good fireproof and heat insulation effect, improving the integrity of kiln refractory and heat insulation, promotes the progress of kiln lining technology classification temperature 1050-1400 ℃, it is widely used in petroleum chemical metallurgical machinery building materials and other industries.

About us

1. Strong professional:

Our company has 30years producing experience in refractory product. Our manager will supervise on a various refractory’ s production materials, process control, quality supervision and package delivery,and ensure the products are 100% qualified.

2. Annual supply:

Our company has passed ISO9001 quality management system certification and CEcertification. And the annual supply of shaped and unshaped refractory product is 28,800-35,000 tons.

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece,Spain, Congo, Angola, South Africa, and Maldives,Jordan and so on. The export figure is more than USD 4 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5.Testing equipment:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Tile blanket thickness 30mm, (2 layers of 20mm compression), hot surface layer, ceramic fiber module thickness of 300mm, total thickness of 330mm. The ceramic fiber module adopts a standard ceramic fiber module with a temperature range of 1260.Considering that the flame sprayed by the nozzle will rebound on the outer wall of the zinc pot and form a smoke wash between the furnace wall and the zinc pot wall, the wind speed is about 18m/s to 23m/s, and there is a certain corrosion. Ceramic fiber module surface brushing two times curing agent, that is resistant to corrosion, but also can resist high wind speed.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module for Boiler Insulation - Refractory Wool Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords