Ceramic Fiber Bonded Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

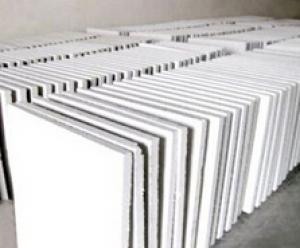

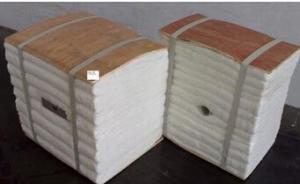

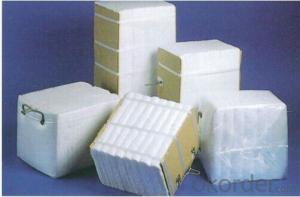

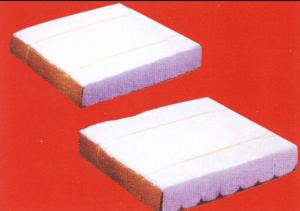

Bonded Modules are produced from ceramic fibers, designed specially for improvement of the thermal insulation of existing industrial furnaces by cementing them on the hot face of other refractories.

CZ and CC quality bonded modules are made from blanket strips, and MX quality is made from felt strips composed of polycrystalline fibers and high alumina fiber, edge-stacked and bonded together.

Classification Temperature 1430°C, 1500°C, 1600°C

Density: 170-210kg/m3

Advantages

► Excellent thermal and physical stability

► Low thermal conductivity

► Low heat storage

► Excellent corrosion resistance

► Faster temperature cycling

► Improves furnace efficiency without replacing a serviceable refractory lining

Availabilities

► 300 x 300 x (30-100)mm

Applications

► Reheating furnaces

► Heat treatment furnaces

► Ladle cover

► Forge furnaces

► Tunnel kilns

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- After 2013, the hot dip galvanizing furnace is usually made of ceramic fiber modules for insulation, as follows:The appearance of new thermal insulation material breaks the inherent heat loss barrier in our country. The new type of thermal insulation material is mainly made of ceramic fiber and heat insulation cotton. It is combined with bolt, nut, carpet blanket, module and compensation blanket to achieve high heat preservation.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth) fumigation characteristics of ceramic fiber cloth: high temperature resistance, low thermal conductivity, low heat capacity, thermal shock;

Send your message to us

Ceramic Fiber Bonded Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords