Ceramic Fiber Module - High Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 pcs kg

- Supply Capability:

- 1000 pcs Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

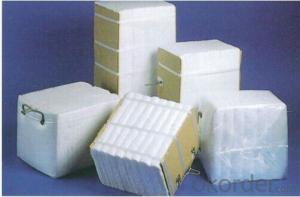

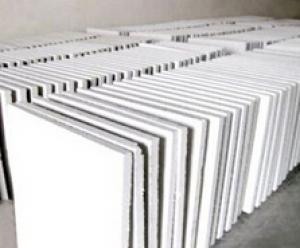

General Information of Ceramic Fiber Module

CNBM ceramic fiber modules are made of ceramic fiber blanket, which are stack folded to form a module with folded edges exposed. Our ceramic fiber modules are available in different classified temperature from 1260 ℃ to 1430 ℃. Our insulating products provide substantial improvement in thermal performance, using our ceramic fiber modules can save your money in energy costs and also can help reduce your operations environmental footprint.

Data Sheet of CMAX Ceramic Fiber Module

Type | STD | HP | HA | HZ | |

Temperature Grade | ℃ | 1260 | 1260 | 1350 | 1430 |

℉ | 2300 | 2300 | 2460 | 2600 | |

Recommended Operating Temp. | ℃ | 1050 | 1100 | 1200 | 1350 |

℉ | 1920 | 2010 | 2190 | 2460 | |

Available Density | Kg/m3 | 160-240 | |||

lb/ft3 | 10-15 | ||||

Color |

| White | White | White | White |

Thermal Shrinkage (24hrs) 128Kg/m3 | % | ≤3 | ≤3 | ≤3.5 | ≤3.5 |

℃ | 1150 | 1250 | 1300 | 1350 | |

Thermal Conductivity (W/m.k) 128Kg/m3 | 800℃ | 0.15 | 0.176 | - | - |

1000℃ | 0.17 | 0.22 | 0.18 | 0.23 | |

1200℃ | - | - | 0.26 | 0.31 | |

Chemical Composition | |||||

Al2O3 | % | 45-47 | 45-46 | 53-55 | 38-54 |

Al2O3 +SiO2 | % | 98.5 | 99 | 99 | 82-90 |

ZrO2 | % | - | - | - | 10-18 |

Size | mm | Length:≤600 Width: ≤600 Thickness: ≤600 Typical size: 305*305*152/203/305 (Non-standard sizes are available upon request) | |||

Anchoring Part |

| 304# and 310# stainless steel Shape: butterfly, rhombus and angled | |||

This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

Features of Ceramic Fiber Module

Easy to install

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Module

CNBM specializes in high-temperature insulation products, providing innovative heat management solutions and energy savings methods for a broad range of industries. CNBM ceramic fiber modules are mainly used in:

Petrochemical process heater

Heat treating furnace

Cement rotary kiln

Glass melting tank

Ceramic firing kiln

Backup insulation

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

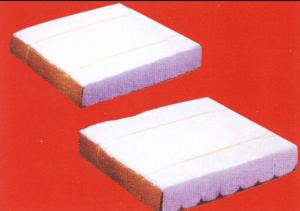

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Tile blanket thickness 30mm, (2 layers of 20mm compression), hot surface layer, ceramic fiber module thickness of 300mm, total thickness of 330mm. The ceramic fiber module adopts a standard ceramic fiber module with a temperature range of 1260.Considering that the flame sprayed by the nozzle will rebound on the outer wall of the zinc pot and form a smoke wash between the furnace wall and the zinc pot wall, the wind speed is about 18m/s to 23m/s, and there is a certain corrosion. Ceramic fiber module surface brushing two times curing agent, that is resistant to corrosion, but also can resist high wind speed.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth) fumigation characteristics of ceramic fiber cloth: high temperature resistance, low thermal conductivity, low heat capacity, thermal shock;

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Fiber Module - High Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 pcs kg

- Supply Capability:

- 1000 pcs Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords