Ceramic Fiber Module 1430 Hz - High-Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 pcs kg

- Supply Capability:

- 1000 pcs Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

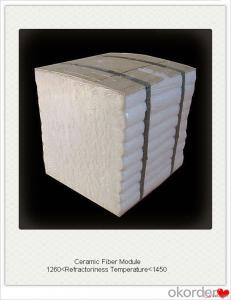

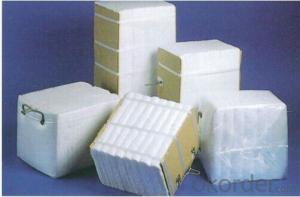

General Information of Ceramic Fiber Module 1430 HZ

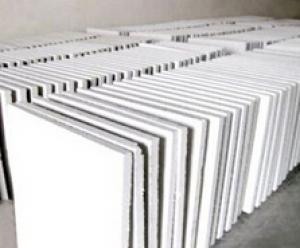

CNBM ceramic fiber module 1430 HZ is made of ceramic fiber blanket, which are stack folded to form a module with folded edges exposed. Our ceramic fiber modules are available in different classified temperature from 1260 ℃ to 1430 ℃. Our insulating products provide substantial improvement in thermal performance, using our ceramic fiber modules can save your money in energy costs and also can help reduce your operations environmental footprint.

Technical Data of Ceramic Fiber Module 1430 HZ | ||

Classification Temperature | ℃ | 1430 |

Working Temperature | ℃ | 1350 |

Color | WHITE | |

Bulk Density | kg/m3 | 160~200 |

Thermal Conductivity (W/m.k) | ||

(Density 200kg/m3) | 800℃ | - |

1000℃ | 0.23 | |

1200℃ | 0.31 | |

Thermal Shrinkage 24hrs, | ℃ | 1350 |

(Density 200kg/m3) (%) | % | ≤3.5 |

Chemical Composition: |

|

|

Al2O3 | % | 38~54 |

Al2O3 + SiO2 | % | 82~90 |

ZrO2 | % | 12 |

Size: Length:≤600mm Width: ≤600mm Thickness: ≤600mm Typical size: 305mm*305mm*152mm/203mm/305mm (Non-standard sizes are available upon request)

| ||

Note: | ||

Features of Ceramic Fiber Module 1430 HZ

Easy to install

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Module 1430 HZ

CNBM specializes in high-temperature insulation products, providing innovative heat management solutions and energy savings methods for a broad range of industries. CNBM ceramic fiber modules are mainly used in:

Petrochemical process heater

Heat treating furnace

Cement rotary kiln

Glass melting tank

Ceramic firing kiln

Backup insulation

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Yes, only the machines require more special

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- After 2013, the hot dip galvanizing furnace is usually made of ceramic fiber modules for insulation, as follows:The appearance of new thermal insulation material breaks the inherent heat loss barrier in our country. The new type of thermal insulation material is mainly made of ceramic fiber and heat insulation cotton. It is combined with bolt, nut, carpet blanket, module and compensation blanket to achieve high heat preservation.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

Send your message to us

Ceramic Fiber Module 1430 Hz - High-Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 pcs kg

- Supply Capability:

- 1000 pcs Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches