Ceramic Fiber Module with Low Thermal Conductivity Veneering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Veneering Module Low Thermal Conductivity

Description for Ceramic Fiber Veneering Module

Ceramic fiber module is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fiber veneering module has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials.The performance of Ceramic fiber module also has difference,and they are suitable for different workong temperatures.

Ceramic fiber veneering module can be used after optional cutting .When Ceramic fiber module storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for ceramic fiber veneering module

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for ceramic fiber veneering module

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

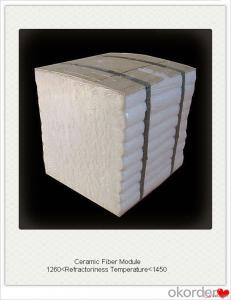

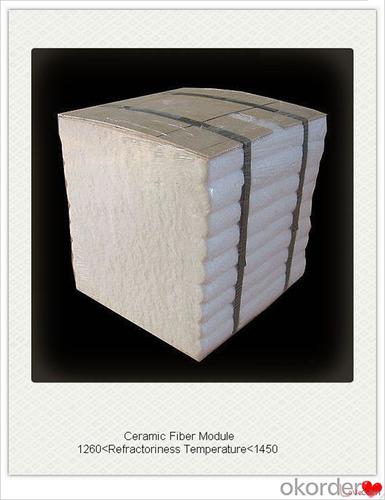

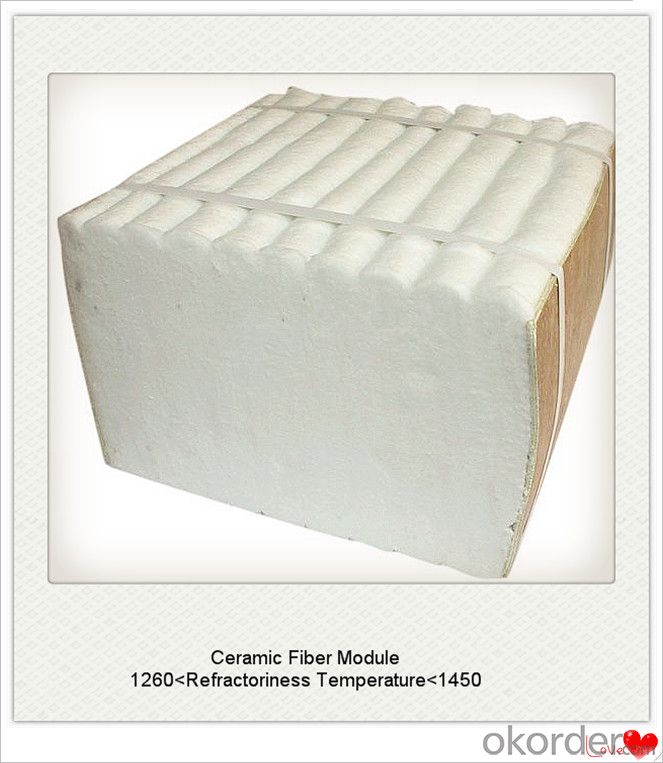

Images for ceramic fiber veneering module

◆Product Process

FAQ

Can we accept OEM for Ceramic fiber module?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, okorder will provide our best products and services for you!

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- After 2013, the hot dip galvanizing furnace is usually made of ceramic fiber modules for insulation, as follows:The appearance of new thermal insulation material breaks the inherent heat loss barrier in our country. The new type of thermal insulation material is mainly made of ceramic fiber and heat insulation cotton. It is combined with bolt, nut, carpet blanket, module and compensation blanket to achieve high heat preservation.

- Q: How to install refractory fiber?

- Good chemical stability; good thermal stability; excellent elasticity, ceramic fiber module is pre pressed state, in lining up after the expansion of ceramic fiber module to enable seamless lining, and can compensate for fiber lining contraction, in order to improve the insulation performance of fiber lining, the overall performance is good; excellent thermal stability and thermal shock resistance the ceramic fiber module; quick installation, and anchors set in the wall lining noodles, can reduce the anchor material requirements.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module with Low Thermal Conductivity Veneering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords