Ceramic Fiber Bulk 1430 Hz - High Quality Insulation Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 KG kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

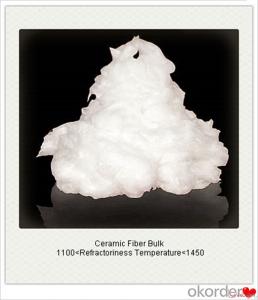

Ceramic fiber bulk 1430℃ HZ

CMAX ceramic fiber bulk is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is the optimum material for the production of fiber textile and also the perfect material for sealing, filling and insulating in high-temperature environment.

The HZ Ceramic fiber bulk have temperature classification 1430℃(2600℉) and the recommended service temperature up to 1350℃(2462℉).

Feature of Ceramic fiber bulk 1430℃ HZ

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

Application of Ceramic fiber bulk 1430℃ HZ

Textile manufacture

Chimney fill

Expansion joint packing

Wet process feedstock

Filtration media

Kiln car infill

Package of Ceramic fiber bulk

Technical Data

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Energy saving: ordinary furnace heat loss, heat rate, furnace insulation can. The holding time of ceramic fiber furnace is ten times higher than that of ordinary furnace, and it is easy to quench and quench.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the miniature furnace chamber, the ceramic fiber furnace can be selected, and once the furnace is formed, the length of the furnace is longer.

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- 1. Ceramic fibers are short fibers that need to be strengthened and toughened by other objects. They are generally toughened by glass fiber and stainless steel wire.2 and high silicon oxygen is long fiber, no need to toughen by other objects.3 short, high silicon oxygen resistance to high temperature, Suzhou Dexin ceramic high silica cloth of silica content is greater than or equal to 96% temperature up to 1700 DEG C.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q: Is the ceramic fiber cloth poisonous?

- Ceramic fiber clothProduct introduction.Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of aluminum silicate fiber: high temperature insulation, heat preservation, fire resistance, noise reduction, insulation, light weight. Disadvantages: compressive resistance, bending force is relatively poor, easy to produce dust, waterproof performance is not very good.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- Refractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- There is no full ceramic fiber material fire shutter;

Send your message to us

Ceramic Fiber Bulk 1430 Hz - High Quality Insulation Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 KG kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords