Ceramic Fiber Module for Cement Rotary Kiln 1430 Hz

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Module

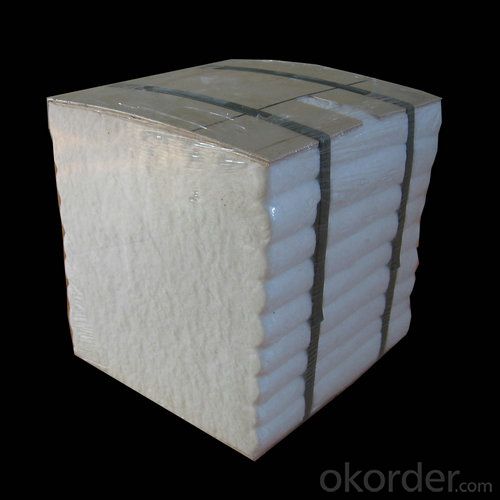

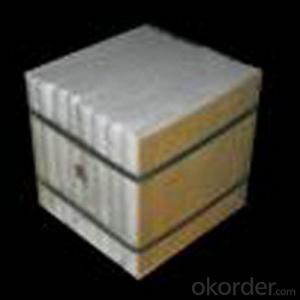

l Okorder ceramic fiber module is made from high-quality spun fiber blanket, and then folded and compressed to certain storage. Ceramic fiber module is a new type of refractory furnace lining product aimed at simplifying and speeding up furnace construction and improving the integrity of furnace lining.

l Okorder ceramic fiber module has a nice white color and formal dimensions; they can be directly fixed on the shell of the industrial furnace. Ceramic fiber module has excellent refractory and insulating effects.

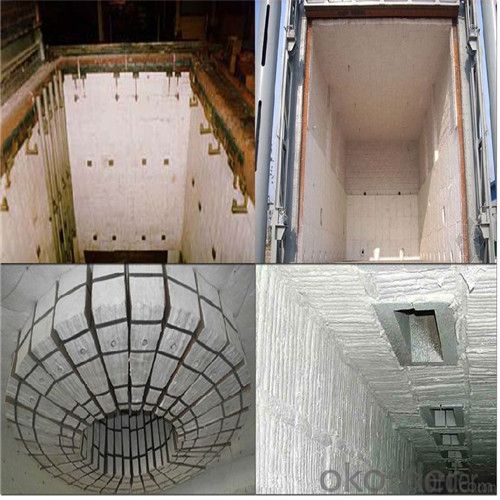

Image of Ceramic Fiber Module

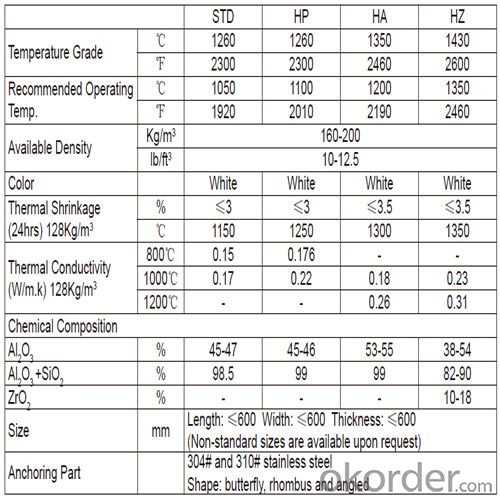

Technical Data of Ceramic Fiber Module

Features of Ceramic Fiber Module

Ceramic fiber module has excellent features including fast and easy installation and low heat storage, and will lower fuel costs. Ceramic fiber module improves the refractory and insulating integrity of furnaces and improves furnace construction process.

Typical Applications of Ceramic Fiber Module

Ceramic fiber module for ceramic industry

Low mass kiln cars

Continuous and batch kilns

Door linings

Glazing, porcelain furnace linings

Ceramic fiber module for power generation

Duct lining

Heat recovery

Steam system

Boiler insulation

Stack linings

Ceramic fiber module for steel industry

Ladle pre-heaters and covers

Heat treat furnace

Soaking pit covers and seals

Heaters and reformer lining

Ceramic fiber module for other applications

Incineration equipment

Burner blocks

Induction furnace covers

Glass tempering furnace

Who We Are

l OKorder is offering high quality Ceramic Fiber Module at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over.

l OKorder annually supplies a full range of products to European, North American and Asian markets.

We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

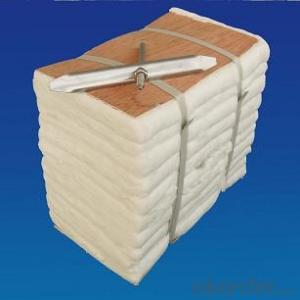

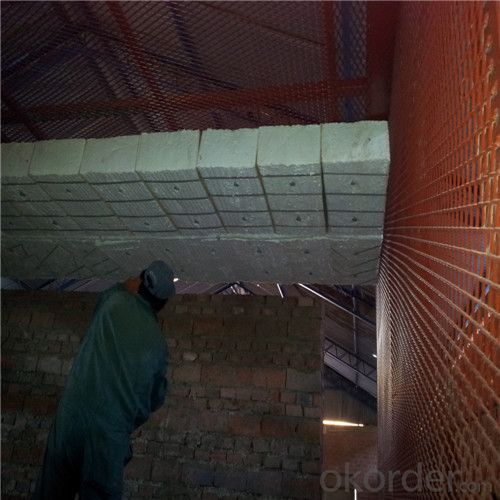

- The arrangement mode of the ceramic fiber module adopts "soldier row type" - along the module compression size. Fiber module arrangement using ceramic fiber blanket folded thickness after 20mm compression, and the use of "U" type nail to keep the 500~700mm distance to the fiber module fixed to insert compensation fiber expansion surface may produce contraction, the structure can avoid the "parquet" arrangement, fiber module for the corner site the expansion caused by uneven phenomenon, "playboy" has the best effect of adiabatic. When the back lining of the furnace top is installed, the quick card matching module is used for temporary fixing with bolts.

- Q: How to install refractory fiber?

- Good chemical stability; good thermal stability; excellent elasticity, ceramic fiber module is pre pressed state, in lining up after the expansion of ceramic fiber module to enable seamless lining, and can compensate for fiber lining contraction, in order to improve the insulation performance of fiber lining, the overall performance is good; excellent thermal stability and thermal shock resistance the ceramic fiber module; quick installation, and anchors set in the wall lining noodles, can reduce the anchor material requirements.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

Send your message to us

Ceramic Fiber Module for Cement Rotary Kiln 1430 Hz

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches