Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10-50mm,6-50mm |

| Width: | 610mm 1220mm | Length: | 7200mm | Chemical Composition: | AL2O3+SIO2 |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1100℃ | Fiber Diameter: | 2-5um,3-5um |

| Shrinkage (1800 ℉, 3h): | -4 | Thermal Conductivity: | 0.09 | Density (kg/m³ ): | 96 |

| Model Number: | 1260 | Brand Name: | Place of Origin: | (Mainland) | |

| Color: | Pure white | Certification: | ISO9001 | Manufacture: | Factory of China |

| Operating temperature: | 1100℃ | Products Name: | bio-soluble ceramic fiber blanket for boiler insulation | Application of ceramic fiber blanket: | boiler insulation |

| Sample: | avilable |

Packaging & Delivery

| Packaging Detail: | PE bag inside,carton box outside,or pp woven bags outside,or according to customers' requirement |

| Delivery Detail: | within 15days after confirm the order |

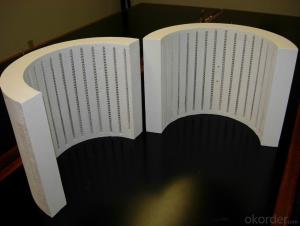

Heat Insulation Bio-soluble Ceramic Fiber Blanket for Boiler Insulation

Product Description

![]()

Description of bio-soluble ceramic fiber blanket:

Technical index of bio-soluble ceramic fiber blanket:

Product Item | ordinary | Standard | high-purity | High Aluminum | Zirconium |

Specification Tem() | 1100 | 1150 | 1260 | 1360 | 1430 |

Classification temperature() | 1100 | 1260 | 1260 | 1360 | 1430 |

Work temperature() | <1000< span=""> | 1050 | 1100 | 1200 | 1350 |

Color | White | Pure white | Pure white | Pure white | Pure white |

Density (kg/m3) | 96 128 | 96 128 | 96 128 | 128 160 | 128 160 |

Permanent linear shrinkage(%)(after24 hours, density 128kg/m3) | -4 (1000) | -3 (1000) | -3 (1100) | -3 (1250) | -3 (1350) |

Thermal conductivity (w/m.k) density 128kg/m3) | 0.09(400) 0.176(800) | 0.09(400) 0.176(800) | 0.09(400) 0.176(800) 0.22(1000) | 0.132(600) 0.22(1000) | 0.76(600) 0.22(1000) |

Tensile strength (Mpa) density128kg/m3) | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 |

Classification temperature() | 1100 | 1260 | 1260 | 1360 | 1430 |

Work temperature() | <1000< span=""> | 1050 | 1100 | 1200 | 1350 |

![]()

Application of bio-soluble ceramic fiber blanket:

1. The material of wall lining and back lining of industrial furnace and the sealing and insulation material of expanded gaps of furnace wall, furnace door, furnace top lid, etc.

2. Insulating material of high temperature

3. Excellent materials to produce module and folded module

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency. Ceramic fiber products (aluminum silicate fiber products) (1) ceramic fiber products (aluminum silicate fiber products) varieties and properties of ceramic fiber products (aluminum silicate fiber products) is the most important indicator of fiber diameter and thermal stability. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- Ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used in recent years because of. The global energy prices rising, energy saving has become a China national strategy background, than other traditional insulation bricks and refractory pouring material such as 10-30% ceramic fiber has been applied more and more widely in the domestic Chinese, the development prospects are very promising.Ceramic fiber products refers to the use of ceramic fiber as raw materials, through processing made of light weight, high temperature resistance, good thermal stability, thermal conductivity of industrial products, low heat resistance of small and mechanical vibration etc., specially used for all kinds of high temperature, high pressure, easy to wear in the environmentScope of application:Ceramic fiber product is a kind of excellent refractory material. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..Technical parameter:The temperature is -100 DEG C, -+1200 DEG CPressure 0-20MPaChemical tolerance pH value 4-14

- Q: What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- Soluble ceramic fiber is a new product and biodegradable. Beijing Fei Pufu

Send your message to us

Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords