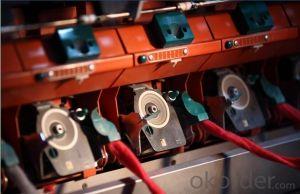

RS30 Rotor spinning machine, Semiautomatic oe machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantages

→ Increase production. The speed of rotor is up to 110,000RPM,Speed of guiding yarn reaches 170m/m

→ 416 spin boxes can be available

→ Carrying out integrate channel to ensure the better sealing, decrease the unnecessary interruption during the fibre transport, which also assures the stable pressure to promote yarn quality

→ It is very easy to operation and replaces spin boxes

→ Lower energy consumption, 5–10% lowers than similar machines for power per ton yarn

→ High rate for finished products

→ Abundant optional: Waxing device, Keep tail device, Yarn Clear, overhead Blower

Integrate self-sucking spin box perfectly combine multi-technology to get best quality of spinning. All focus on the following advantages:

→ Self-sucking,long passage, large capacity for remove impurity

→ The maximum rotor speed can be up to 110,000RPM

→ Integrate channel ensures the better sealing and stability pressure

→ Non-cover cavum of opening roller can avoid the fibre or impurity accumulation.

→ Many parts of spin boxes are gotten through die-casting, which reduce the replacing parts quantity and improve the unanimity of the spin boxes

→ Many kinds and series of units enlarge the range of yarn, and increase the range of material

→ Series standard units enlarge the spinning range and yarn range

→ It is easy to disassemble and install the rotor, opening roller, withdraw nozzles and other key parts without any tools

Semiautomatic piecing device is used to do the preparation before the piecing, such as worker should finish lift creel, find out yarn end, cleaning spin box, etc. But for yarn feeding, yarn sink, yarn draft, and winding are completed instantaneously by the device, which is constituted by the lever device, electro-magnet and high precision time controller device. The unique combination of electromechanical components ensures the time error of piecing less than 0.01 second. This advantages are as following:

→ The piecing can be completed even speed over 60000R.P.M and keep good quality

→ Only one minute training, operator’s piecing quality can meet the standard

→ The quality of piecing can’t be affected cause of different operators

→ Success ratio of piercing is more than 95%

→ The strength of the piecing does not affect the following procedures Semi-auto doffing system:

→ Conveyor belt can be used as the temporary store for doffing; while bobbin is full, it is conveyed to the tail side of the machine

Reliable impurity collection system:

→ Backward and forward running waste conveyer belt & cleaning cart can completely remove the spin box waste, reduce labor intensity, and improve spinning condition

Strong trash system

→ Spin box use strong trash system, and more efficiency for fiber and waste separate, Improve yarn quality & qualified ratio

Lower energy consumption

→ Through long time experience comparation, power consumption is lower of the same type

Electronic controlling system: Adopting loop-locked technical & intelligent controlling system:

→ Parameter display (rotor speed, opening roller speed, yarn drawing speed, feeding speed, traverse speed, yarn length, shift production)

→ Spinning technology parameters display (draft ratio, negative pressure)

→ Semi-automatic piercing technology parameters display

→ It is easy to set or edit technique parameters

→ Technological parameter info management can save huge parameters

→ Photoelectric sensor for yarn broken changed to non-contact measure, better anti-pollution and operational reliability

→ Emergency off device to avoid accidents

→ Adopt remote computer system to realize network management by control PLC systems and machines running

→ Inverter control for Opening roller speed, yarn drawing speed, feeding speed and traverse speed, convenience for technological parameter adjustment

→ Negative pressure alarm device can avoid yarn defects cause by whole machine negative pressure decline

→ Keep tail device: To avoid the yarn break, and reduce the working strength to increase the working efficiency

Yarn Clear

Features

CCD character check

digitwise operation, can’t be effected by temperature and humidity, good consistency, higher detection sensitivity, stability system and antijamming electromagnetism

Absolute measure

Diameter inspect can avoid effect by yarn speed and material, and get real-time status and average status for each spindle

Perfect yarn clear function

According rotor spinning features setting 6 slub channels, 2 snick channels, 1 wrong count channel and 1 stick channel

System can get whole machine average status

According the setting range, indicate and cut unusual spindle, with individual meter

Perfect defects statistical functions

It can calculate each spindle defects quantity, help user find and analyze reasons of problems in time, improve quality and efficiency. According to user requirement to setting permitted defects for unit length, get best fit for quality and efficiency. auto correcting current Can improve components reliable, avoid interference of cinder and light source System is isolate design, antijamming

Slub | Snick | Wrong count | Piercing | Stick | |

Channel quantities | 6 | 2 | 1 | 1 | 1 |

Setting Diameter | 100-450 | 50-100 | 100-150 | ||

Setting Length | 0-630 mm | 0-630 mm | 0-12m |

Since RIFA established, all the time we devoted ourselves to developmental research for spinning technical, made customer get more good and economic product. These guide RFRS series open end spinning popular those years, Now it? is already widely used for jean fabrics, knit goods, cotton flannel, upholstery fabrics and industry cloth, etc. Main products are jeans, T shirt, Sportswear, bed clothes, upholstery fabrics, caps, hosiery and PU leather, etc. These are benefit from:

→ The adaptability for material and yarn count is more broad

→ Succeed for Non-cotton fiber produce, such as blend polyester-cotton, hemp cotton yarn, viscose yarn, filament yarn and blended wool , etc.

→ OE yarn twist is tight inside and loose outside, good for gigging or pile

→ Economic yarn count range is expanded together.

→ Yarn is even, polished and spotless, less piercing and defects, big package, bring high efficiency for next processing

From promote the first rotor spinning in the domestic market, at present our rotor spinning is the most stable and mature' self-automatically rotor spinning machine, now there are nearly 1000 sets equipments total 200,000 have a good running in the customers' factory.

Items | Unit | Technology data |

RFRS30 | ||

Yarn count range | tex(Ne) | 120~16(5~36) |

Range of rotor speed | r/min | 40000-110000 |

To ± - diameter Series | mm | Φ33、Φ38、Φ42、Φ50 |

Range of fibre length | mm | <40 |

Opening roller speed | r/min | 5000~10000(变频可调) |

Sliver count range | Tex(g/5m) | 5000~3000(15~25) |

Maximum winding speed | m/min | 170 |

Draft range | 32~220 | |

Twist range | T/M | 200~2250 |

Pitch of spin boxes | mm | 216 |

MAX spindles | spindle | 416 |

Per section | spindle | 16 |

Dimension of cylinder tube | mm | Φ54x170 |

Cone | 4°20′、2°20′、3°30′ | |

Maximum | mm | Φ300x150 |

Maximum weight of yarn package | Kg | ≈4.5 |

Can dimension | mm | Φ400x900,Φ350x914 |

Pressure | Pa | 5000~9000 |

Noise | dB | <85 |

Total motor power rating | Kw | 124(416 spindles) |

Total exhausted air | M3/h | 6210 |

- Q: Why the first industrial revolution in the cotton textile industry innovation will cause the British national yarn shortage?

- In the process of transformation from the workshop to the large industrial machinery industry, due to the further development of the enclosure movement, the majority of the farmers lost the land to survive, they had to wander to the city to make a living

- Q: What is spinning down?

- Unearthed early spinning wheel, generally by the stone or pottery by a simple polished, the shape is different, mostly drum-shaped, round, flat round, quadrilateral and other like, and some tread also painted decoration.

- Q: How does the mechanical wave generated in the spinning process work?

- The sum bar means that the two columns are superimposed on each other

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- The domestic basic industry is weak, the basic parts can not keep up, affecting the quality of textile machinery products and mechanical and electrical integration level. Textile machinery product development and the lack of organic cooperation, affecting the use of textile products effect. Policy does not match, affecting the competitiveness of domestic textile machinery products. In view of these problems, China's textile industry has adopted a series of measures to vigorously develop the basic equipment of textile machinery, the introduction of foreign textile machinery technology, differentiated development strategy, and the introduction of the corresponding policy of supporting the development of textile machinery, and achieved good results The

- Q: Is there a textile industry in the Qin Dynasty?

- Chinese machine textile originated in five thousand years ago Neolithic spinning wheel and waist machine. Western Zhou Dynasty with the traditional performance of the simple mechanical reeling car, spinning, looms have emerged, the Han Dynasty widely used jacquard machine, oblique loom, after the Tang Chinese textile machinery is maturing, greatly promoted the development of the textile industry.

- Q: Who invented Jenny spinning machine?

- He suddenly thought: if a few spindles are arranged vertically, with a spinning wheel driven, not all of a sudden spinning more yarn it? Hargreaves was very excited and tried to do it right away. In the following year he made a new spinning machine with eight spinning spindles with a spinning wheel, and the effect was eight times higher. 1764 made to his daughter Jenny named spinning machine. This is the first multi-spindle hand spinning machine, equipped with eight spindles, with a roller feed fiber strip, suitable for cotton, wool, hemp fiber spinning. The emergence of Jenny's spinning machine caused a lot of hand-spinning spurs at the time, and they rushed into the home of Hargreaves to destroy the machine.

- Q: Is the textile machine made of those accessories?

- There is no concept of spinning machine, spinning and weaving are separate, and spinning and weaving process is very long, do not want you to imagine only one or two equipment can be, the entire production process involved in the equipment up to a dozen

- Q: What are the related fields of textile engineering?

- Business training objectives: The professional training with textile engineering knowledge and ability, in the textile enterprises, scientific research, teaching and other departments engaged in textile design and development, textile design, textile production quality control, production and technological transformation and the initial management and management capacity Senior engineering and technical personnel.

- Q: What are the mechanical characteristics of textile machinery?

- The complete set of textile machinery is also subordinate to the process. For example, according to the cotton spinning process configuration of complete sets of machines, models arranged in order, the number of fixed relationship between the number of machines are determined by the process requirements. Another example is the scope of the work of the weaving machine weaving products, the need to configure the appropriate range of work inspection cloth, the amount of cloth and dyeing and finishing equipment, also belong to the set of. Therefore, the complete set of textile machinery not only exists in a factory, also exists between the plant and the plant.

- Q: China's textile industry prospects of printing and dyeing ?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

Send your message to us

RS30 Rotor spinning machine, Semiautomatic oe machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords