Centrifugal Hot Oil Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.RY centrifugal hot oil pump2.Reasonable structure

3.Use reliable

4.Long service life

5.Applicated to high temperature

RY centrifugal hot oil pump

Advantage

1.simple structure

2.good performance

3.reliable operation

4.high-temperature

5.small volume,save cost

Brief introduction

RY Thermal oil pump series is made with advanced technology and have high efficiency.

It can work steadily long without leakage under heat conditions. It has no additional cooling system and can be used safely and reliably. It’s widely used in the thermophore heating system in our country.It’s entered a lot of industry fields such as petroleum, rubber, plastic, pharmacy, spinning,

printing and dyeing, road building, food and so on, used to transport weak-corrosive high temperature.the liquid not containing solid granules. The using temperature is ≤370°C,and it is an ideal thermal oil circulation pump.

Application scope

Capcacity: 1-500m3/h

Temperature: -20°C-350°C

Head: 10-125m

Theory: Centrifugal Pump

Application: petro-chemical,oil industry,plastic and rubber industry etc

Typical Application

1.Petroleum Industry

2.Chemical Industry

3. Pharmacy and Health

4. Environmental and Water treatment

5.electroplating industry

6.Environmental protection

7.food service industry

8.Printing and dyeing area

9.textile industry, etc

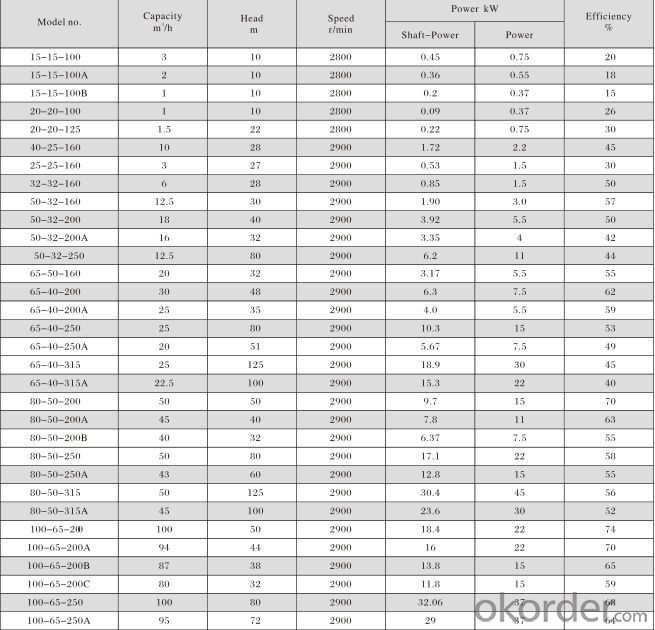

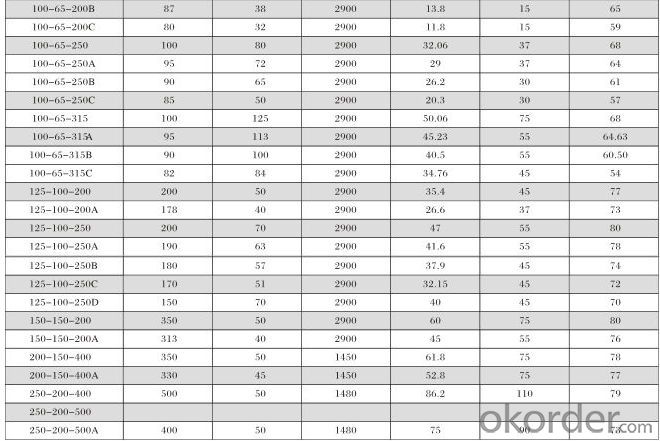

Technical data

.

- Q: What are the uses and precautions of magnetic pumps?

- Notice of use:1. prevent particles from enteringHas the ferromagnetic impurities and particles into the magnetic actuator and bearing friction is not allowed.The transport of crystallization or precipitation of the medium to the flushing (after pumping water, poured into the pump cavity drained after running 1min), in order to ensure the service life of bearing.The transport medium containing solid particles, the pump flow tube inlet filter.

- Q: There are 6 pumps, two indoor fire hydrant pumps, two spray pumps, two outdoor pumps, three units, one master and one spare control cabinet. From the control room to the control cabinet, is there only 3 lines or 9 lines?... How do I get it? Where does the hydrant line come from?

- Spray pump in addition to remote direct Kai, there are modules to start function, that is, on the cabinet to add control module, bus linkage pump, in addition to the pressure switch, directly pumping function, a total of three functions.

- Q: How to select metering pump head?

- When it comes to metering pump heads, the usual problem is when they measure acid, chlorine, fluoride, and hydrogen peroxide. Due to the difference in concentration and operating temperature, it is difficult to determine the specific pump head material.

- Q: What are the starting and stopping procedures for centrifugal pumps?

- The use of centrifugal pump can be divided into three steps, namely, start, run, stop.Start: you should do the following preparation before starting:(1) check the water pump equipment in good condition.(2) the bearings are filled with oil, the oil level is normal, and the oil quality is qualified(3) all the inlet valves of the centrifugal pump are opened.(4) pump water injection or vacuum pump diversion (except for flow), open the vent valve exhaust.(5) check the leakage of shaft seal. It is advisable to fill the seal with a little drop of water.(6) the motor rotates in the right direction.

- Q: There are second cutting, third cutting, why three times?

- So some pumps are written in the back of XXXX-125A or B, that is, the impeller nominal diameter is 125, A is through a cut, B is the 2 cutting. To reach the applicable conditions, only the calculation is not enough, but also after cutting to test to determine.

- Q: Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- 1. rpmOperating speed is the actual rotation speed of a pump (or motor) at work.Rated speed is the maximum speed that can operate normally for a long time under rated pressure. If the pump exceeds the rated speed, the work will cause insufficient oil absorption, vibration and noise, the parts will suffer cavitation damage, life expectancy.Minimum steady speed is the minimum speed allowed for normal motor operation. At this speed, the motor does not appear crawling phenomenon.

- Q: What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump is a pumping machine used in the field, while the concrete pump truck is a truck mounted pump.

- Q: Metering pumps related matters

- 2) change the metering pump diaphragmTrouble is often encountered when the old diaphragm is removed. Provide some additional advice on how to remove the old diaphragm.After in the pump head loose, remove the pump head before the stroke length adjustment to the 10% position. To ensure that the electromagnetic axis has sufficient pressure to maintain its connection firmly, so that you can unscrew the diaphragm.The pull end torque from the Jack out of the screw. Seize the liquid counter clockwise rotation. There is a slight resistance that can unscrew the diaphragm.Chemical 3 measurement may end in fluid crystallization, resulting in a one-way valve ball and seat valve does not work.In the end inhalation metering pump may have a gas leak. Hydraulic end suction side connector may lack O ring or suction valve connection loose.3) flow monitoring and measurement of a high viscosity medium, in the process of liquid delivery received a flow failure signal, how can we solve this problem?Move the hydraulic end by loosening the 4 pump head screws. Rotating stroke length to 10%, and seize the hydraulic end, and then slide out of the screw hole, then the screws do not touch them, but still control the back and diaphragm. Then rotate the component counter clockwise, with a slight resistance, and the diaphragm will loosen from the electromagnetic axis. If the diaphragm is not loose, use some grease on the contact surfaces of the diaphragm and the electromagnetic shaft. After a few minutes, gently tap the diaphragm with a small plastic hammer. Then proceed again in accordance with the above description.

- Q: What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- A single-stage pump is a pump with only one impeller. 2, a multistage pump is a pump with two or more impellers. The multistage pump can increase the pressure and lift the head higher. Level 1 means a booster impeller.

- Q: What are the characteristics of the piston pump?

- main features 1 、 double plunger structure, small pressure pulsation, long life of gem ball.2 、 imported precious stones and precious stones to ensure accurate flow.3, through the RS232 interface and computer communication, can be directly controlled by the computer.

Send your message to us

Centrifugal Hot Oil Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords