Ceiling partitions for interior walls/ceiling baords

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Ceiling partitions for interior walls

Ceiling partitions for interior walls/ceiling baords

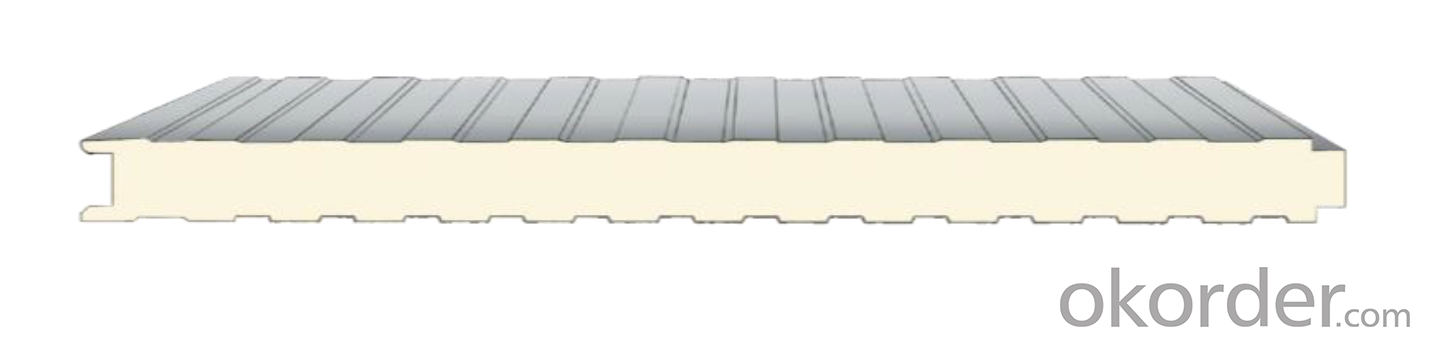

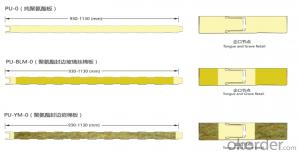

Partition plates are used for the inner partition walls and suspended ceilings of buildingsand also the walls of a mobile container house

The partition panel has good self-load-bearing performance。

The partition panel has good air tightness.

The partition plate has good thermal insulation and anti-cold bridge function.

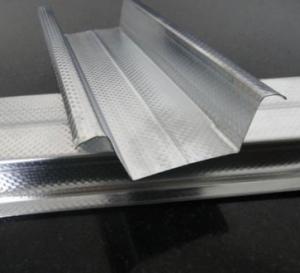

The surface layer of the partition plate can be color coated steel plate, aluminum foil, lithographic steel plate and stainless steel.

- Q: What is the nanometer board?

- The United States and nano-board is the MDF, and now a lot of businesses are the MDF into a variety of names to deceive consumers, this thing is to do with the plate furniture. If it is the choice of furniture, then do not recommend the choice of plate furniture, because the density of formaldehyde is too serious, and the indoor temperature is slightly higher there is pungent taste, do not listen to what the business people do not have a taste certificate, those are cheating The consumer. My aunt bought the plate furniture for 3 years there are flavor it Density board this thing is very cheap, so the plate furniture good bargain. There are businesses that are shameless to use the particleboard to do furniture, but also the name of solid wood particles. I faint, that thing like the same thing. See inside you will vomit. Are broken wood weeds, as well as pungent nausea taste. Now want to buy furniture floor or buy solid wood a little better, although your point but with the rest assured. At least the wood thing is natural, even if the wood is also something natural than those who work with the rest assured. My family's furniture for 4 sets, and in front of three sets of furniture is what plate wood combination, regret dead, not not strong is pungent taste. Finally changed the set of solid wood, but not the kind of good wood mahogany. After all, not a wealthy, but with a lot better, did not taste do not say, but also strong I said that I have 4 sets of furniture experience, hope to adopt.

- Q: What is the smart sheet?

- Smart sheet can be interpreted as intelligent sheet metal, King coconut latest release of intelligent paint-free board is smart sheet 1, intelligent simulation Using a selection of 5A-class model to ensure that each piece of intelligent paint-free board standards the best; Mianqi the surface of the impregnated film coated paper, using a digital scanning, digital imaging, digital printing technology to ensure that the finished color texture clear and realistic. 2, intelligent security Joined the UV hidden map recognition, digital layer security, intelligent information reading, physical visual security of the four recognition system to ensure that every user can rest assured that the use of King coconut products. 3, intelligent customization Choose the most representative, to undertake China's thousands of years of wood culture of natural precious wood varieties, and synchronized supporting the decorative lines and hardware, customized for consumers to enjoy the private sector, for the vast number of consumers to create a multi-functional intelligent home Living space, its beauty is no less than a variety of finished furniture. 4, intelligent experience: Through the Tablet PC, mobile phones, computers and other tools to show a variety of styles and style effects, to eliminate the consumer in the selection of the concerns, bring the sheet industry in the unprecedented ease and convenience.

- Q: Do you know the top of the wardrobe?

- The top solid wardrobe is made of high quality plate, special process, moisture resistance, formaldehyde emission meet the E1, E0 environmental standards, with anti-deformation, anti-mildew pest control, anti-acid, anti-scratch, recyclable The use of double-track single pull pulley, the last round of the United States DuPont pu materials, the next round of modified pps material, with wear-resistant, muffler, bearing the strong and so on. With the top of a special top and bottom seal, completely put an end to dust. The top of the wardrobe pulley is the international top of the sliding system, tight seal.

- Q: Baosteel Cr2, Cr3 plate what material

- CR2 is the standard of ISO 3574, equivalent to GB03 (GB / T 5213, or EN 10130), or standard SPCD (refer to JIS 3574), or American Standard CS Type A, B (refer to ASTM A1008M-07) ; CR3, equivalent to GB04 (GB / T 5213, or EN 10130), or standard SPCE (refer to JIS 3574), or American Standard DS Type A, B (refer to ASTM A1008M-07);

- Q: Huaxiang plate how?

- Huaxiang plate is a well-known brand in Guangdong Province, the quality is very good! Decoration master are recommended to use this one sheet.

- Q: Not the best material if the material is certainly K gold and then titanium and the like plate metal is conventional glasses frame is not a good argument of course the same material brand bigger work is certainly better

- Not the best material if the material is certainly K gold and then titanium and the like plate metal is conventional glasses frame is not a good argument of course the same material brand bigger work is certainly better

- Q: Europe to send cabinet cabinet board board what advantage

- Europe to send cabinet cabinet board accounted for 80% of the entire cabinet plate, its excellent real decision of the cabinet durability and environmental protection. Europe to send cabinets cabinet body board formaldehyde emission is very low, all in line with the European E1-class environmental standards. Surface smooth, high density, good bending performance, easy to deformation. The cohesion of the plate is good and the nail is strong. Base material structure is uniform, dense, open material will not appear loose collapse, plate quality and stability. Europe to send cabinet cabinet board board all the German hammer edge machine edge, PVC edge of the German imports of the world's top Swiss brand, to 1.5MM, and the use of the world's advanced plastic coating technology, Finished, and in the process of sealing at the same time trimming, polishing treatment, so that the edge smooth, neat, beautiful, good sealing, waterproof moisture, to ensure that Europe to send cabinets cabinet life.

- Q: How about a pair of plates?

- Shuangyou I saw the online information is a wood company in Zhejiang, but the fame is not king coconut, Moganshan such a large brand of large plates. Influence is also inadequate.

- Q: E0.E1 level is the level of formaldehyde content, the specific number is how much

- The E0 grade of the sheet is the concept of formaldehyde emission limitation in the new national standard GB / T9846.1-9846.8-2004. The standard divides the formaldehyde limit level into three levels, namely: E1 level free formaldehyde release limit ≤5.0mg / L </ FONT> (meet the domestic standard), E1 free formaldehyde release limit ≤ 1.5 mg / L </ FONT> (in line with European standards), E0 level free formaldehyde release limit ≤ 0.5 Mg / L </ FONT> (the world's top standard). ???? E0 grade plate although the environmental standards are higher, but because it does not contain green moisture-proof agent and adhesive, its toughness and moisture resistance is relatively low, easy to tide fracture, generally used as furniture substrate, not suitable for use in the kitchen wet Environment. In addition, due to the higher price of E0 grade plate, consumers are usually unbearable, generally choose E1 grade plate.

Send your message to us

Ceiling partitions for interior walls/ceiling baords

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Productivity Center of Building Materials Industry Co.,Ltd.

Productivity Center of Building Materials Industry Co.,Ltd.