Cationic Water Treatment Chemicals Raw Materials

Description:

Anionic polyacrylamide is a kind of water-soluble linear polymer, supplied as free-flowing particles status without dust or

colloid, perfectly soluble in water. The product can be dissolved fast for its particle form. Different polyacrylamides have

different active groups, which flocculate different suspended particles for filtration and separation. The product is easily

dissolved in water, insoluble in any organic solvent. In many industries, this product is used for flocculation, thickening,

cementation, anti-scaling, colloidal stabilization, drag reduction, film formation, gelling, biological materials and so on

This product is technically named Polyacrylamide, which is a water soluble macromolecular polymer. It is insoluble in most of

the organic solvents. It generates a good flocculation and can decrease the resistance between liquids. The amide group with

many substance affinity adsorption ,formation of hydrogen bonds forms bridging between the adsorbed ions in generating

floc and accellration fallou.

Specifications

1) Anionic PAM;

2) Molecular weight: 10 million

3) Inherent content: 90% min;

4) ISO 9001: 2008 standards;

Anionic polyacrylamide:

Specifications:

Item | Anionic type |

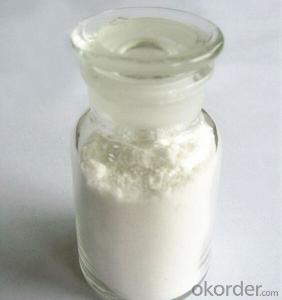

Appearance | white fine-sand shaped powder or grain |

Molecular weight | 6million~22million |

Solid Content (%) | ≥90 |

Degree of hydrolysis | Low/medium/high |

Dissolving Time (mins) | ≤40 |

Note: our product can be made upon your special request. |

Application Field:

1. Oil field exploration and development, geology, water conservancy, Coal exploration.

2. Used for drinking water purification, water purification, municipal sewage sludge, municipal solid waste and industrial

effluent;

3. Paper-making industry for the clarification of liquid caustic soda, fiber dispersing agent, can improve the beating, the

filler retention agents, paper strengthening agent, can be used to improve the treatment rate and the white water recovery;

4. Used in textile, carpet industry, sizing, quick-setting cement, synthetic resin coating. Photosensitive polymers,

adhesives, dispersing agent, as well as agricultural soil gel, slurry stabilizers, soil amendments;

5. The sugar syrup for the industry to clarify the agent;

6. Can be used as aquaculture feed additives and adhesives;

7. Oil field water treatment to deal with the recovery of oil.

Advantage:

1. Easy to dissolve, dissolve time 40min.

2.It is with high performance and it can adapt to a variety of conditions.

3. The dose is small and high efficiency.

4. High molecular, molecular weight 22million.

5. High purity, without impurity.

Application Method:

1. The product should be prepared for the water solution of 0.1% as concentration. It is better to use neutral and desalted water.

2. The product should be scattered evenly in the stirring water, and the dissolving can be accelerated by warming the water (below 60 °C).

3. The most economical dosage can be determined based on a preliminary test. The pH value of the water to be treated should be adjusted before the treatment.

Package and Storage:

1. The solid product can be packed in inner plastic bags, and further in polypropylene woven bags with each bag containing 25Kg.

2. This product is hygroscopic, so it is should be sealed and stored in a dry and cool place below 35°C.

3. The solid product should be prevented from scattering on the ground because the hygroscopic powder can cause slipperiness.