Casting Iron Manhole Cover with Different Designs and Colors for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

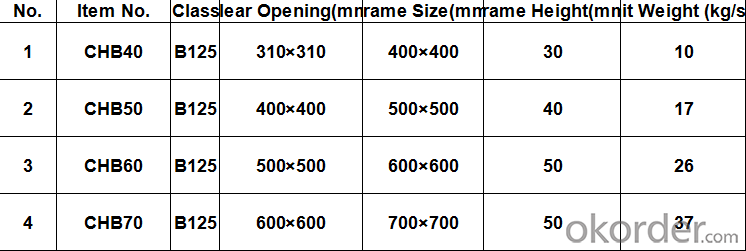

Specification

1) Product information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs .

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

4) Coating

a) Cold applied black bitumen

b) Without coating Product information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

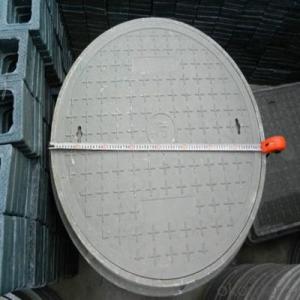

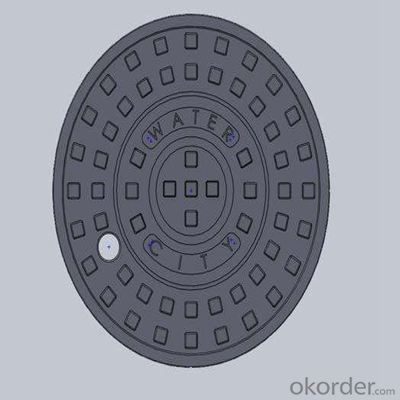

Pictures

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

Q :Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

Q: Can I change your package Way?

A: Yes, we can make the form of the package and transportation according to your request, but if any additional charge occurs, you have to pay for it.

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Steel parts are not familiar. But after spraying, the powder should be divorced from the adhesive force is too low, try to provide the surface roughness of the casting

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

Send your message to us

Casting Iron Manhole Cover with Different Designs and Colors for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches