Casting ductile iron valve foundry supply precision body(shell-mold casting)customized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard or Nonstandard: | Standard | Structure: | Control | Pressure: | Medium Pressure |

| Power: | Solenoid | Material: | Plastic | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | 1/8" | Place of Origin: | Zhejiang China (Mainland) |

| Model Number: | DSF-1/8-FF-A | Brand Name: | masoneilan control valves | Color: | Customised Pantone Color |

| Holding Power VA: | 5.5VA | Certification available: | Yes | Sample Time: | 3-5days if you want to customize your logo |

| MOQ: | 200pcs | Logo: | Any printing we can make for you just send the design to us! | OEM: | Professional OEM manufactory |

| Holding current: | 0.18A/24VAC | Voltage: | 12/24VAC, 12/24VDC, 6-40VDC,110VAC and 220VAC with solenoid |

Packaging & Delivery

| Packaging Detail: | 20PCS/CTN |

| Delivery Detail: | 35 days (according to the order quantity) |

Specifications

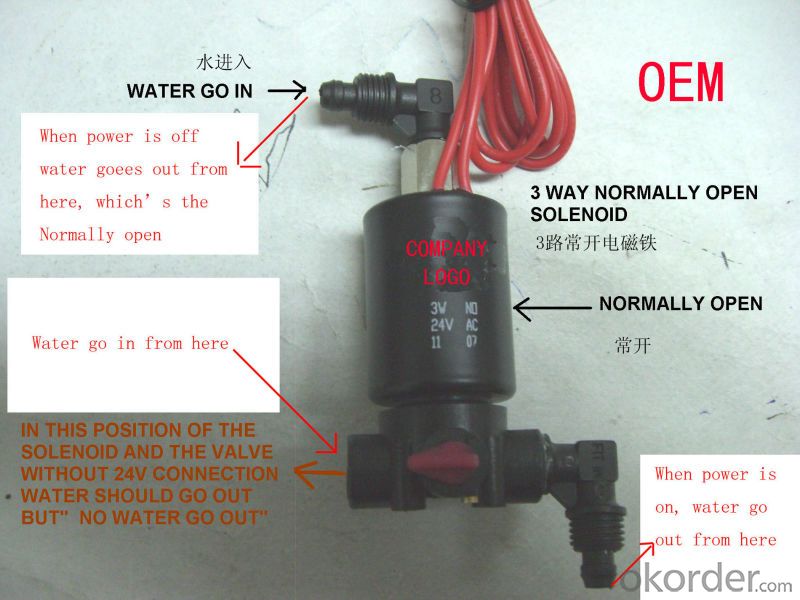

masoneilan control valves DSF-1/8-FF-A in 1/8" inch size

Control by the irrgation solenoid to on-off the valve

OE

masoneilan control valves : DSF-1/8-FF-A

Economical irrigation valve designed primarily for the residential and light commercial use, and it features solid construction, convenient operation and reliable performance. This solenoid valve series have 3 options: without Manual, or with Manual, or with flow control, for each type, they can be matched our irrigation solenoids (S391 series plastic encapsulated & S392 series metal shell) produced by our company at the voltage of 6-40VDC latch, 12/24VAC, 12/24VDC, 110VAC etc.

PS. The solenoids assembled with the valves are optional, for the specific solenoids specifications refer to the irrigation solenoids section of this catalogue. Option of 12/24VAC, 12/24VDC.6-40VDC Latch, 110VAC ,220VAC etc

The superiority to purchase the whole valve with solenoid in our company:

1)Regarding to the price, overall buy must buy cheaper than separate.And also the cost of shipment will be cheaper if you have to let us send the solenodis to the other valves factory to assemble.

2)Regarding to the delivery time. If we produce the overall we can send them together and will be faster than the sending them separate by different factory with different delivery time and production scheduling..

3)Regarding to the quality assurance, it is most important because we can test them overall and it will be easier to find the problem and repair them fast..If have the problem we can solve them much easier and more convenience..Or as you know if you have the different solenoids and valves supplier, if you have problem found in your company it will be much more inconvenience and also will cost a lot of time and money to change from two different suppliers..That will be a big problem..Anyway some problem if we produce the overall we can found them more easier such like the wrong dimensions,wrong performance..Because some problem may not be tested by separate testing.

4)For us more experience both in producing the soelnoids and valves will be a big quality assurance for all the customers and also easier to find the problem and research and development the new products..

Features:

1) Option of without manual, with manual or flow control

2) Valve body made of Aging-proof Corrosion-Resistant Reinforced Nylon for the long life duration.

3) Rugged synthetic rubber diaphragm provide the lead-proof seal

4) Special valve configuration with the self-cleaning function, debris-tolerant.

5) Self-aligning bonnet permits fast and easy maintenance

6) High-flow, low-friction-loss design.

Specifications:

Calibre inch | Max Pressure | Flow Rate | Rated Voltage | Initial Power | Holding Power |

1/8 | 0.069 ~ 1.05 | 12 ~ 120 | 24VAC / 50Hz | 10.5VA | 5.5VA |

Pressure Loss

Flow Control | Pressure Loss |

12 | 32 |

20 | 34 |

40 | 31 |

60 | 23 |

80 | 25 |

100 | 38 |

120 | 55 |

- Q: Z11H/Y forged steel gate valves H/Y what does that mean?SZ45H S what do you mean?Blow 2Z41YGY-40P, what do you think?What does NKZ61H vacuum valve NK mean?What does DS/Z64H water seal valve DS mean?Specific valve number how to see ah, detailed information, thank you!

- The meaning of valve number:Valve type Z, J, L, Q, D, G, X, H, A, Y and S respectively: gate valve, globe valve, throttle valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, relief valve, drain valve.The connecting codes for valves are 1, 2, 4, 6, 7, respectively: internal thread, 2, outer thread, 4, flange, 6, welding, 7, pair.Valve transmission mode code 9, 6, 3, respectively, said: 9, electric, 6, pneumatic, 3, turbo worm.Body material Z, K, code Q, T, C, P, R and V respectively: grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steel.Seat sealing or lining R, T, X code, S, N, F, H, Y, J, M, W respectively: austenitic stainless steel, copper alloy, plastic, rubber, nylon plastics, fluorine plastic, Cr stainless steel, hard alloy, rubber lining, Monel alloy, valve body material.

- Q: What valve is the DN 25?

- This is only the aperture of the valve. It does not represent the form of the valve.

- Q: What does 3/4''mean in the name of the valve?

- 4. [case]Galvanized steel pipe DN50, sch 20Galvanized steel pipe "NB2", sch 205., the outer diameter and DN, NB relationship is as follows:------DN (mm), --------NB (inch), -------OD (mm)15-------------- 1/2--------------21.320--------------3/4 --------------26.725-------------- 1, ----------------33.432-------------- 1, 1/4, -----------42.240-------------- 1, 1/2, -----------48.350-------------- 2, -----------60.365-------------- 2, 1/2, -----------73.080-------------- 3, -----------88.9100-------------- 4, ------------114.3125-------------- 5, ------------139.8150-------------- 6, ------------168.3200--------------- 8------------219.1The above data is referenced only in ASTM A53. Please note that there are some differences in external diameter with different specifications.

- Q: What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- The difference between the three is as follows: pneumatic valve]: driven by compressed air valve. Operation principle: the pneumatic control valve is composed of actuating mechanism and regulating mechanism. The actuating mechanism is a thrust component of the regulating valve, which generates the corresponding thrust according to the pressure of the control signal, and drives the regulating mechanism to move. The valve body is the regulating component of the pneumatic control valve. It contacts the regulating medium directly and regulates the flow of the fluid. [hydraulic valve]: the use of oil and other liquid pressure driven valve. The working principle of the hydraulic valve control valve pressure control valve flow control valve control valve control valve to control the direction of hydraulic system oil flow direction or liquid flow through the valve two, the working principle of the valve core and the valve body and valve off valve two-way hydraulic lock check valve to make oil movement off or on, changing the direction of the oil flow, so as to realize the hydraulic actuator and its driving mechanism of starting and stopping or changing the direction of movement. [electric valve]: with electric actuators to control the valve, so as to achieve the valve opening and closing. The utility model can be divided into two parts, the upper part of which is an electric executor, and the lower half of which is a valve. Also called air conditioning valve. The electric valve is usually connected by the electric actuator and the valve, and it becomes an electric valve after installation and debugging. The electric valve uses the electric energy as the power to switch on the electric actuator to drive the valve and realize the valve switching and regulating action. So as to achieve the purpose of switching or regulating the pipeline medium.

- Q: Is the filter also valve?

- The filter is in fact a low inlet and outlet shut-off valve with no disc and valve head. The filter screen is arranged in the middle, to control the filter according to the number of travel impurities. Usually follow the valve to tender, but not valves.

- Q: The expert can tell me how to install this valve, and what fittings to use on both sides

- It looks a bit like the butt weld butterfly valve. The two sides are welded to the pipe. There is a step on either side of the valve. Overhead welding

- Q: According to the original valve installed on it, but never demolished, I am afraid to force over, will not be broken? The old valve, that part of the remaining three tubes tight.

- The new spool to buy off, installed in the old spool that. You don't have the same brand. You may not be able to load it. It's better to have the same brand

- Q: Look at the flow chart, some of the valves are marked with FV, and some are marked with XV. What does that mean?And what do you mean by the Cv value on the valve nameplate?I hope the heroes give a clear explanation ah, it is best to give an introduction of this knowledge of the web site oh.Thank again.

- Is the flow through the valve. That is to say, when the valve is fully open, flow through the valve size.

- Q: Why is the valve on the pipeline not the same size as the pipe, and how much of a crude pipe can be given? Thank youI'm sorry, I didn't make it clear that when doing pipe work in the factory, for example, 60 of the pipe, and in this pipeline to install the valve to choose DN50, and so on.

- If the valve from the opening and closing role, then the valve bore should be the same diameter with the pipe, big waste, small, increase resistance.If the role of the valve is adjusted, and that caliber will be different from the pipe diameter, this is not to reduce the cost of the problem, is a result of calculation, and this calculation results with flow, pressure drop and valve resistance curve.For example, control valve, usually smaller than the pipe diameter, such as pressure reducing valve, will be smaller than the pipe diameter to two.

- Q: How can the material be checked by valve approach? What experiments do you need?

- (8) the throttle valve does not test the tightness of the closing parts, but the strength test and the tightness test of the stuffing and the gasket shall be carried out.(9) the pressure test, the valve closing force only allows a person's normal physical strength to close; not augmented with tools like leverage (except torque wrench), when the hand wheel diameter is greater than the wait at 320mm, allowing two common off.(10) with a sealed valve, should be taken out of packing for sealing test, sealed after the official closed, check whether leakage. When gas is used as a test, check the water in the stuffing box. When sealing test is carried out, the upper seal is not allowed to be in the tight position.(11) when the valve with drive device is tested and its tightness is tested, the sealing test shall be carried out by using the driving device to close the valve. For manual drive units, seal test shall also be done with the actuating closing valve.(12) the by-pass valve installed on the main valve after the strength test and the sealing test. The strength and tightness test of the main valve is carried out. The main valve should be opened when the closing member is opened.(13) iron valve strength test, the application of Pratia tapping valve and valve cover, check whether there is any leakage.(14) the valve test, in addition to the provisions of the plug valve to allow sealing surface oiling, other valves are not allowed in the sealing surface of the oil test.(15) when the valve pressure test, the blind plate on the valve pressure should not be too large, so as to avoid deformation of the valve, affecting the test results (cast iron valve if pressed too tight, will be damaged).(16) after the valve test pressure, should promptly remove the water and clean the valve, should also be prepared for the test record.

Send your message to us

Casting ductile iron valve foundry supply precision body(shell-mold casting)customized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords