Cast Resin Transformers from SGB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Why cast resin transformers made by us?

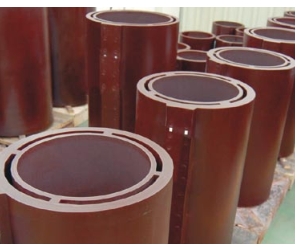

The range of SGB-SMIT cast resin transformers includes power ratings up to 25 MVA and rated

insulation voltages up to 36 kV as well as converter, distribution and special transformers. With its

over 30 years of experience in the construction of cast resin transformers, SGB-SMIT‘s scope of

special expertise is one of the largest world-wide, a fact which is reflected by the extremely high

quality level such as our MTBF (mean time between failures) of over 2,400 years.

Thanks to their special design, SGB-SMIT cast resin transformers offer a range of features which, on

the one hand, distinguish them from other cast resin transformers in terms of technology and, on the

other hand, make them a highly reliable and extremely safe solution.

The operative benefits for you, our customer, are the following:

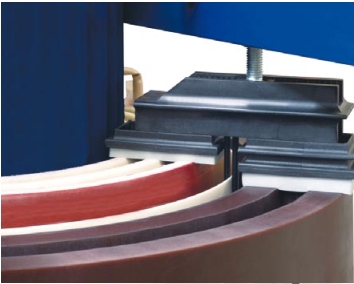

• Thanks to the multi-layer winding principle, high surge voltages and switching

voltages are handled safely.

• Cooling ducts provide thermal reserves and allow for overload.

• The use of glass-fibre reinforced plastics (GFK) in the encapsulated windings

provides resistance to temperature shocks.

• Long service lives are ensured.

With production starting in the late 1970‘s, SGB-SMIT were one of the first manufacturers of cast

resin transformers, thus we are able to offer our customers the benefit of our extensive experience

and know how. This extraordinary know-how is reflected by a especially high quality score, e.g. an

MTBF of over 2,400 years.

It goes without saying that SGB-SMIT cast resin transformers meet all the established

quality conditions: Fire classification F1 • Environmental class E2 • Climate classification C2

And as a matter of course, the product sector Cast-Resin Transformers at SGB-SMIT has been

certified according to ISO 9001 and ISO 14001.

The extremely high quality of SGB-SMIT cast resin transformers has a name: Uni|Q.

Uni|Q is synonymous with the special quality and test features which make our cast resin

transformers so unique:

• Several Decades of Experience

· Comprehensive operating experience world-wide including international production sites

· First-class international references in all sectors

· Ample know-how and long-term experience in the field of onshore wind power plants

including special cooling systems: Jet System

· Transformer system tailored to open sea conditions for offshore wind power plants with many

years of operating experience: Safe-System

· Optimum solutions for all industrial applications with extreme climate conditions – no matter

whether extremely hot or cold: All Climate Safe System

• Unique design

· The multi-layer winding is electrically the best and most reliable option. Thus, almost all oil

distribution transformer manufacturers apply this principle. Millions of these have been

securing the energy supply in many countries for several decades world-wide. SGB-SMIT is the

only manufacturer of cast resin transformers who uses this principle!

• Computerised monitoring of the production process

· Based on a precise analysis according to

automotive standards, all relevant production

parameters of each transformer are recorded

continuously and compared online to the

set-point values. The next production step

only follows if everything is found to be correct.

· This system makes it possible to achieve a

uniform level of quality over large production

quantities at all locations of the SGB-SMIT

Group on an international basis

- Q: (Warning: I have no knowledge of electrical equipment) I just bought a black light. It can fit into my lamp, but I noticed that the lamp had a label that read To reduce risk of fire, use a 60 watt type a lamp max. The bulb is 75 watts. Is it okay to use the bulb or should I not use it?

- Please follow the directions on your lamp. The 75 Watt bulb will throw out more heat and need more power and your lamp is not rated for that. This could result in a fire. It is not worth the risk. Don't fool around with electricity.

- Q: how is this possible?

- Theoretically, yes they do. Practically, no. If load resistance decreases, V out decreases some, if load resistance increases, V out increases some. All wires have a resistance, even the wires from a supply point to an electrical outlet.

- Q: i have a situation with my computer i don't know what it is but i have done a lot of test so please help me identifying this and how to solve it My build: CPU: i7 5820k MOBO: x99 g1 gaming 5pPSU: seasonic m12 750wGFX: g1 gaming gtx 980 ti

- Using water pipes as temporary grounding solution is not bad. But. You or someone must solve the grounding issue in your house or apartment properly. The next time you have thunder storms or similar disturbances, your electrical equipments and electronics at home might be broken, one after another. You have quite a big problem there, do not under estimate it!.

- Q: i want to make a bulb on and off at intervals of say half an hour. readymade timers available in shops(india) costs much and does not support shorter intervals like half an hour. any cheaper electronic circuit which can do this control? from where can i get the circuit or its diagram?

- Depending on your skills, a CMOS 555 timer chip could probably drive a solid state switch (triac) for this interval although a more reliable timing, especially if you want exactly a 50% duty cycle, by feeding the timer output into a counter, so that the 555 cycles say 32 times (once a minute about) for each change of state of the selected output. Smaller cycle times are more stable.

- Q: I don't understand how oil and gas industry has anything to do with electrical engineering jobs??Am I not seeing this because currently I am working as a electronics engineer ? This is how I am thinking about this - Oil and gas industry , digs up oil , provides it to our cars and trucks so they can run. Now I don't understand how or where Electrical engineers come into play into this ?? Please make me understand. I want to know.P.s: I am an entry level electronics engineer, with a degree in Electrical engineering , Currently I am located in Houston, texas.

- A great deal of electric power is used in extracting oil and gas from the ground, transporting it through pipelines, separating and refining the crude products and distributing the products. Electrical engineers design the required electrical equipment and the associated electric power distribution and control systems. In some situations, electric power must be generated on site rather than purchased from electric utility companies. In addition, electrical engineers are involved in the process instrumentation and control system design. The process control includes both computer systems and specialized electronic equipment.

- Q: I need to cut a hole through 2(ish)cm of metal, or some sort of composite material I have at home to feed a few wires through. Is it possible to do it without any electrical equipment?

- A pneumatic drill

- Q: i am going to ship my furniture including my electronics( refrigerator, recorder, laptop, dishwasher, drier, etc) i want to now if the voltage in USA is 240v as in Dubai or 110v and i case of difference i want your advice i`ll ship them or not

- You shouldn't ship them, better to sell them and buy new ones, in the US they use 110, not like Dubai and some appliances like the fridge will not function well since its manufactured for Dubai were its hot and humid, as for your lap top no harm taking it, you can get an adapter for it.

- Q: Is your MOS 52c? How is it?

- Army equipment is often electrically powered. It's up to the Utilities Equipment Repairer-an essential member of the Army electrical maintenance team-to make sure all the electrical equipment remains in excellent working order. Utilities Equipment Repairers maintain and repair electrical equipment such as electric motors and electric tools. The Utilities Equipment Repairer is responsible for supervising and performing maintenance on utilities equipment and special purpose support systems. Some of your duties as a Utilities Equipment Repairer may include: Maintaining, testing, and repairing electric motors in many kinds of machines, such as lathes and pumps Inspecting and repairing electrical equipment Inspecting and repairing electric instruments, such as voltmeters Replacing worn gaskets and sealing in watertight electrical equipment Maintaining and repairing gasoline engine systems, air conditioner electrical systems and portable heater fuel/electrical systems SSG Schramm US Army 15 years OIF 2003

- Q: I seem to have an adverse affect on computers and electrical equipment. My sheer presence seems to upset them.I'm not a stranger to technology, so it's not me being dim, but more and more often I've crashed supermarket checkouts, I was even sent to the other side of a store by my husband because the computer our details were being loaded on crashed time after time. I walked away and all was well in the world (well the store anyway). My laptop (even with the latest updates) has a mind of it's own sometimes. Coincidence or am I electrically overcharged?

- You must be the illegitimate child Zapdos.

- Q: anyone knows some practical situation when a resistance maybe used to model part of a circuit, a component or electrical equipment

- english.cxem /infrared/ir3-5.g Anita

Send your message to us

Cast Resin Transformers from SGB

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords