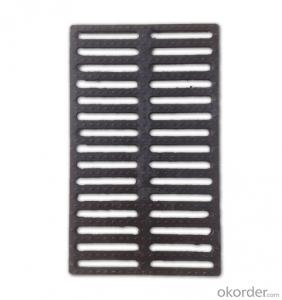

Cast OEM ductile iron manhole covers with high quality for industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5)we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| TD1221 | D400 | 1220*675 | 1378*831 | 100 | 216 |

| TD1222 | D400 | 1220*675 | 1370*830 | 150 | 80.5 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- Corundum sand: the main mineral composition is corundum alpha -Al2O3, used for investment casting, ceramic mold casting shell materials. The olivine sand: the main mineral composition of olivine (MgFe) 2SiO4, used in cast iron, non-ferrous alloy castings and high manganese steel casting molding sand and the core sand. Silica resources in nature resources, but suitable for casting with high SiO2 content of natural silica sand is not too much. Since 1951, China has carried out a general survey of the casting sand resources in the territory, but mainly limited to the main traffic lines and major industrial cities. Survey results show that Chinese can be used for natural silica sand casting is very rich in resources, a wide range of distribution. Inner Mongolia Zhelimumeng, natural silica sand reserves amounted to hundreds of millions of tons, the particle shape close to the circular, the content of SiO2 is about 90%. Fujian, Jinjiang Dongshan sea sand, the content of SiO2 is 94 to 98%, with a low volume of mud, are good natural silica sand. Are Duchang, Yongxiu Jiangxi County Xingzi, a large number of Quaternary lacustrine deposition of silica sand, the content of SiO2 is about 90%, low iron content, alkaline oxide less, uniform size, is a good lake sand. Guangzhou, Hunan and other places have abundant easily broken weathered sandstone, processing artificial silica sand, the content of SiO2 in more than 96%, can be used for the production of steel castings. Jiangsu Nanjing red sand, sandy mud pure, moderate, strong permeability, good viscosity, high silica content, less water, fine particles, pulls out the casting is smooth, stable quality, can be made of cast iron and non-ferrous metal parts of the sand and core sand

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

Send your message to us

Cast OEM ductile iron manhole covers with high quality for industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches