Casing Seamless Pipe of Grade J55 with API Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

1. Commodity Name: Carbon Seamless steel pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

Length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. Application:

Carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C D/A D/P T/T

8. Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

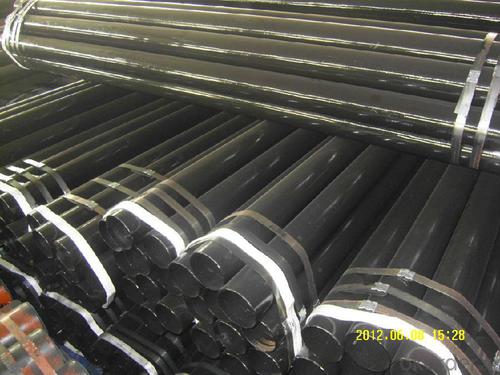

Seamless Steel Tubes Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q: How are steel pipes used in the automotive manufacturing industry?

- Steel pipes are commonly used in the automotive manufacturing industry for various purposes such as exhaust systems, chassis frames, and structural components. These pipes provide durability, strength, and resistance to corrosion, making them ideal for applications that require high performance and reliability.

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used in water well construction due to their durability, strength, and resistance to corrosion. They provide a reliable and long-lasting solution for extracting and transporting water from underground sources.

- Q: How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes are generally more durable and have a higher resistance to heat, pressure, and corrosion compared to PVC or copper pipes. They are commonly used for applications that require strength and longevity, such as in industrial settings or for transporting high-pressure fluids. However, steel pipes can be more expensive and heavier than PVC or copper, making them less suitable for certain residential or lightweight applications. Ultimately, the choice of material depends on the specific requirements and budget of the project.

- Q: Can steel pipes be used for structural applications?

- Yes, steel pipes can be used for structural applications.

- Q: How are steel pipes used in the manufacturing of food processing equipment?

- Steel pipes are commonly used in the manufacturing of food processing equipment due to their durability, strength, and resistance to corrosion. These pipes are used to transport various food products such as liquids, powders, and gases within the equipment. They are also utilized in the construction of frames, supports, and structures for food processing machinery, ensuring stability and longevity. Additionally, steel pipes are often employed in the creation of heat exchangers, which are crucial for heating or cooling purposes in food processing equipment.

- Q: How are steel pipes used in the manufacturing of wind turbines?

- Steel pipes are an integral component in the manufacturing of wind turbines, primarily in the construction of the tower and the foundation. The tower of a wind turbine is typically constructed using large steel pipes that are welded together to form a sturdy and tall structure. These pipes provide the necessary strength and stability to support the entire weight of the wind turbine and withstand the strong forces generated by the rotating blades. In addition to the tower, steel pipes are also used for the foundation of the wind turbine. The foundation requires a strong and stable base to ensure the turbine remains upright and secure. Steel pipes are commonly used to create the deep foundation piles that are driven into the ground to provide support and stability. These piles are typically made of thick-walled steel pipes, which are driven deep into the ground to anchor the wind turbine and prevent it from toppling over. Furthermore, steel pipes are utilized in the transportation of electricity generated by wind turbines. Once the wind turbine converts wind energy into electrical energy, the electricity is transmitted through an internal electrical system to the base of the tower. From there, the electricity is often transferred through underground cables to a substation for distribution into the power grid. Steel pipes are used to protect and encase these cables, providing insulation and ensuring the safe transmission of electricity. Overall, steel pipes play a crucial role in the manufacturing of wind turbines by providing structural support, stability, and efficient transmission of electricity. The durability and strength of steel make it an ideal material for withstanding the harsh environmental conditions and the immense forces associated with wind turbine operation.

- Q: What is the difference between steel pipe and concrete pipe?

- The main difference between steel pipe and concrete pipe lies in their material composition. Steel pipes are made from steel, which provides strength, durability, and resistance to corrosion. On the other hand, concrete pipes are made from a mixture of cement, aggregates, and reinforcing materials, offering advantages such as fire resistance and the ability to withstand high pressure. While steel pipes are commonly used for transporting fluids and gases, concrete pipes are often used in drainage and sewage systems.

- Q: How are steel pipes protected against microbial corrosion?

- Steel pipes are protected against microbial corrosion through various methods, such as applying protective coatings or linings on the pipes' inner and outer surfaces. These coatings act as a barrier, preventing the contact of microorganisms with the steel surface, thereby reducing the risk of microbial corrosion. Additionally, biocides and inhibitors can be added to the pipe's contents or injected into the pipeline to inhibit the growth and activity of microbes, further protecting the steel pipes from microbial corrosion.

- Q: How do you prevent steel pipes from freezing?

- To prevent steel pipes from freezing, there are several measures you can take: 1. Insulate the pipes: Use foam insulation sleeves or wrap the pipes with insulation tape. This will help maintain the temperature of the pipes and prevent them from freezing. 2. Seal any gaps or cracks: Inspect the area around the pipes and seal any gaps or cracks with caulk or expanding foam. This will prevent cold air from entering and freezing the pipes. 3. Install heat cables: Heat cables can be wrapped around the steel pipes to provide a steady source of heat. These cables can be controlled by a thermostat, ensuring that the pipes stay above freezing temperature. 4. Keep the temperature above freezing: In areas where extreme cold weather is common, it is advisable to keep the indoor temperature above freezing, even if the property is vacant. This will help maintain a suitable temperature for the pipes and prevent freezing. 5. Open cabinets and faucets: In particularly cold weather, open cabinet doors in kitchens and bathrooms to allow warm air to circulate around the pipes. Additionally, allowing faucets to drip slightly can also prevent freezing by keeping water flowing. 6. Drain the pipes: If you are leaving your property unoccupied during freezing weather, it is recommended to drain the pipes completely. This can be done by shutting off the main water supply and opening all faucets until no water remains. This minimizes the risk of freezing and potential damage. Remember, prevention is crucial in protecting steel pipes from freezing. By implementing these measures, you can significantly reduce the risk of frozen pipes and potential costly repairs.

- Q: Can steel pipes be used for agricultural irrigation?

- Yes, steel pipes can be used for agricultural irrigation. They are durable, resistant to corrosion, and have high tensile strength, making them suitable for transporting water over long distances in agricultural fields. Steel pipes also have the advantage of being able to withstand high pressure, making them ideal for irrigation systems that require efficient water distribution.

Send your message to us

Casing Seamless Pipe of Grade J55 with API Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords