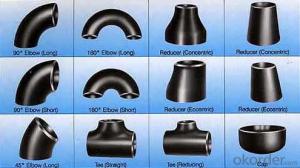

Carbon steel pipe fittings ELBOW FLANGE TEE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks.

Pipe fitting work is done in many different settings: HVAC, manufacturing, hydraulics, refineries, nuclear-poweredSupercarriers and Fast Attack Submarinescomputer chip fab plants, power plant construction and other steam systems. Pipe fitters (sometimes called simply "fitters") are represented in the USA and Canada by the United Association of Journeymen and Apprentices of the Plumbing and Pipe Fitting Industry of the United States and Canada.

Fitters work with a variety of pipe and tubing materials including several types of steel, copper, iron, aluminium, and plastic. Pipe fitting is not plumbing; the two are related but separate trades. Pipe fitters who specialize in fire prevention are called Sprinklerfitters, another related, but separate trade.

Materials, techniques, and usages vary from country to country as different nations have different standards to install pipe.

Elbow are an English alternative rock band consisting of Guy Garvey (vocals, guitar), Richard Jupp (drums, percussion), Craig Potter (keyboards, piano), Mark Potter (guitar, backing vocals), and Pete Turner (bass guitar, backing vocals). They have played together since 1990, adopting the Elbow band name in 1997, and have released six studio albums: Asleep in the Back (2001), Cast of Thousands (2003), Leaders of the Free World (2005), The Seldom Seen Kid (2008), Build a Rocket Boys! (2011), and The Take Off and Landing of Everything (2014). All of their studio albums, as well as B-sides compilation Dead in the Boot (2012), have placed in the top 15 of the British album chart and seven of their singles have placed in the top 40 of the British singles chart.

In 2008 Elbow won the Mercury Music Prize for their album The Seldom Seen Kid, and in 2009 they won the Brit Award for Best British Group In 2012 they released "First Steps", the BBC theme for the 2012 London Olympics

Specifications

Standard: ASTM A234 WPB, JIS, DIN, EN, GOST

Use for Oil, Gas, Subwatering act.

45/90/180 degree, LR/SR Elbow

ASTM A234 WPB ELBOW :

| ||||||||

| we are manufacturer for carbon steel pipe and fittings,like 45deg,90deg,180deg,L/R OR S/R,bend , | ||||||||

| equal or reducing tee, CON reducer, ECC reducer, pipe cap,flange. | ||||||||

| CON AND ECC REDUCER: CARBON STEEL,STAINLESS,STELL,ALLOY STEEL | ||||||||

| NOMINAL DIAMETER | BIG OD1 | SMALL OD2 | HEIGHT(MM) | |||||

| MM | SERIES A | SERIES B | SERIES A | SERIES B | 51-711 | |||

| 25*15--1500*1400 | 33.7-1524 | 32-1520 | 21.3-1420 | 18-1420 | ||||

| MATERIAL: A234WPB,A283,A105,A53,A106,API5L | ||||||||

| STANDARD: ASTM/ANSI,DIN,ISO,GB,JIS,BS ,GOST | ||||||||

| OTHERS: | ||||||||

| 1. Special design available according to requirement | ||||||||

| 2. All the production process are made under the ISO 9001:2000 strictly. | ||||||||

- Q: How is steel used in the production of tools and hardware?

- Steel is commonly used in the production of tools and hardware due to its strength, durability, and versatility. It can be forged, shaped, and tempered to create various types of tools such as wrenches, hammers, screwdrivers, and saw blades. Steel's hardness allows it to withstand heavy use and resist wear and tear, making it ideal for tools that require high strength and toughness. Additionally, steel can be easily machined and sharpened, enabling the production of precise cutting edges and intricate designs, further enhancing its utility in the manufacturing of tools and hardware.

- Q: How do steel products contribute to the construction of dams and reservoirs?

- Steel products play a vital role in the construction of dams and reservoirs due to their strength, durability, and versatility. They are used for various purposes such as reinforcement in concrete structures, fabrication of gates and penstocks, and lining the tunnels and spillways. Steel products ensure the structural integrity of these massive water projects, providing stability and withstanding the immense pressure exerted by the water. Moreover, steel's resistance to corrosion makes it ideal for long-term use in these water-intensive environments. Overall, steel products are essential components that contribute to the successful construction and functionality of dams and reservoirs.

- Q: What are the applications of steel mesh?

- Steel mesh has a wide range of applications in various industries and settings. It is commonly used in construction as reinforcement in concrete structures, providing strength and durability. Steel mesh is also utilized in the manufacturing of fencing, gates, and barriers for security purposes. It is employed in the automotive industry for seat frames, airbag deployment, and radiator grills. Additionally, steel mesh finds applications in filtration systems, animal enclosures, and even artistic installations.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each with their specific uses. Some common types include compression springs, extension springs, torsion springs, and flat springs. Compression springs are designed to resist compression forces and are used in applications such as automotive suspensions, mattresses, and industrial machinery. Extension springs, on the other hand, are designed to absorb and store energy when pulled apart and are commonly used in garage doors, trampolines, and various mechanical devices. Torsion springs provide a rotational force and are commonly found in clothespins, garage door systems, and various small appliances. Flat springs, also known as leaf springs, are used in applications that require high strength and flexibility, such as automotive suspensions, agricultural equipment, and heavy machinery. Each type of steel spring has its unique properties and applications, making them essential components in various industries.

- Q: What are the different types of steel products used in the manufacturing of camping equipment?

- Some of the different types of steel products used in the manufacturing of camping equipment include stainless steel utensils, steel tent poles, steel camping stoves, and steel fire pits.

- Q: What are the different types of steel reinforcing bars?

- There are various types of steel reinforcing bars, commonly known as rebar, used in construction. These include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Each type possesses unique characteristics and is selected based on the specific requirements of the construction project.

- Q: What are the different types of steel cladding and roofing available?

- There are several types of steel cladding and roofing available in the market, including corrugated steel sheets, standing seam steel panels, metal shingles, and steel tiles. Each type offers unique features and benefits, such as durability, weather resistance, and aesthetic appeal, allowing individuals to choose the most suitable option for their specific needs and preferences.

- Q: How do steel products contribute to the agriculture and farming sector?

- Steel products contribute to the agriculture and farming sector in several ways. Firstly, steel is used in the manufacturing of machinery and equipment essential for agricultural activities, such as tractors, combines, plows, and irrigation systems. These machines help increase efficiency, reduce labor, and improve productivity on farms. Additionally, steel structures, such as barns, silos, and storage facilities, provide durable and secure spaces for storing crops, livestock, and equipment. Steel is known for its strength, durability, and resistance to weather conditions, making it ideal for protecting agricultural resources. Furthermore, steel is used in the construction of infrastructure such as bridges and roads, which play a crucial role in connecting farms to markets and facilitating the transportation of goods. This infrastructure ensures that agricultural products can reach consumers in a timely and efficient manner. Overall, steel products contribute significantly to the agriculture and farming sector by enhancing productivity, providing storage solutions, and supporting the necessary infrastructure for the smooth functioning of the industry.

- Q: What are the uses of steel in the construction of hotels and resorts?

- Steel is widely used in the construction of hotels and resorts due to its exceptional strength and durability. It serves various purposes such as providing structural support, forming the framework of the building, and reinforcing concrete structures. Steel beams and columns are used to create large open spaces, allowing for flexible and efficient floor plans. Additionally, steel is utilized in the construction of staircases, elevator shafts, and roofing systems. Its fire-resistant properties and ability to withstand extreme weather conditions make it an ideal choice for ensuring the safety and longevity of hotels and resorts.

- Q: What are the common types of steel products used in the cosmetics and beauty industry?

- The common types of steel products used in the cosmetics and beauty industry include stainless steel tweezers, scissors, makeup brushes, nail clippers, and eyelash curlers.

Send your message to us

Carbon steel pipe fittings ELBOW FLANGE TEE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords