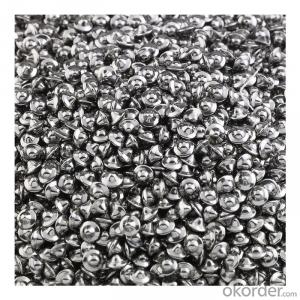

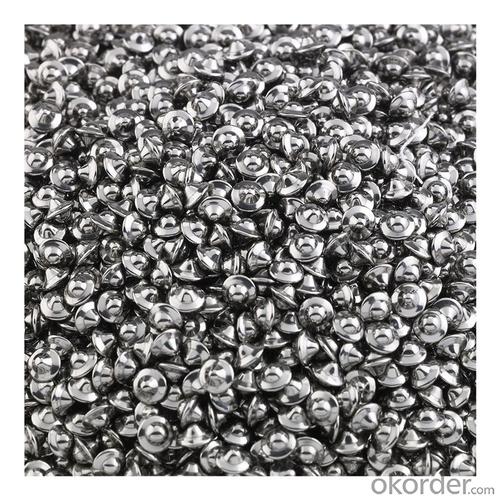

AISI316 Stainless Steel Shot Ball for Grinding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI316 Stainless Steel Shot Ball for Grinding

1. Austenitic stainless steel ball with higher corrosion resistance than AISI304 balls.

2. Shows good hardness.

3. AISI316L has a lower carbon content.(maximum 0.03%)

4. Balls are provided in the passivated condition.

5.International standard:

X5CrNiMo1712 / 316 / 1.4401 / Z6CND17.11 / 08KH16N11M3 / 0Cr17Ni12Mo2

6. Applications:

Special bearings, pumps and valves, aerosol and dispenser sprayers, utilised in the foodstuff, paper, chemical, rubber, Military, textile industry, applications in photographic devices, Medical instruments, quick couplings, recirculating balls, ink cartridges, jewels.

| Stainless steel ball AISI 316L | |||||||||

| 1. Material | AISI 316L/ JIS SUS 316L/ Wks 1.4404 | ||||||||

| 2. Size Range | 1mm-180mm | ||||||||

| 3. Grade | G40-1000 | ||||||||

| 4. Hardness | 25-39 HRC | ||||||||

| 5. Characteristic | (a)Excellent resistance to corrosion(apart of chloridric acids) (b)Not hardenable austenitic inox (c)Material 1.4404 has a higher corrosion resistance than material 1.4401 | ||||||||

| 6. Magnetic | NO | ||||||||

| 7. Application | Photographic chemicals, bleaches, dyes, inks and nitric aicds Vggressive applications without mechanical efforts | ||||||||

| 8. Chemical composition | |||||||||

| C% | Si% | Mn% | Cr% | Ni% | Mo% | P% | S% | N% | |

| min. | --- | --- | --- | 16.5 | 10.0 | 2.0 | --- | --- | --- |

| max. | 0.03 | 1.00 | 2.00 | 18.5 | 13.0 | 2.5 | 0.045 | 0.015 | 0.11 |

| 9.Packing | Standard: 10kg or 20kg per carton, 1 ton per pallet or as customer required | ||||||||

| 10.Conditioning | dry or oiled | ||||||||

| 11.Delivery time | Stock within a short time or 35 days. | ||||||||

- Q: How is steel used in the manufacturing of oil and gas pipelines?

- Steel is commonly used in the manufacturing of oil and gas pipelines due to its strength, durability, and resistance to corrosion. It is used to construct the main body of the pipeline, providing a secure channel for the transportation of oil and gas over long distances. The steel pipes are welded together to form a continuous pipeline, ensuring the integrity and safety of the system. Additionally, steel is often coated with protective layers to further enhance its resistance to corrosion and external damage.

- Q: What are the different types of steel coatings and finishes available for steel products?

- There are several types of steel coatings and finishes available for steel products. Some common options include galvanized coatings, which provide corrosion resistance through a layer of zinc; powder coatings, which are applied as a dry powder and then cured to form a durable finish; and paint coatings, which can be applied in various colors and provide both protection and aesthetic appeal. Additionally, there are specialty coatings such as chrome plating, nickel plating, and epoxy coatings, each offering unique properties and benefits for specific applications.

- Q: How is steel used in the production of agricultural equipment?

- Steel is used in the production of agricultural equipment due to its durability and strength. It is commonly used to manufacture components such as blades, plows, and machinery frames, as well as storage tanks and containers. The properties of steel make it ideal for withstanding the harsh conditions and heavy usage that agricultural equipment typically endures, ensuring longevity and efficiency in farming operations.

- Q: What are the different types of steel products used in the oil and gas industry?

- There are various types of steel products used in the oil and gas industry, including pipes, valves, fittings, and structural components. These steel products are typically made from carbon steel or alloy steel, which offer high strength, durability, and corrosion resistance. Additionally, specialized types of steel, such as duplex stainless steel, are used in applications where resistance to extreme temperatures, pressures, and corrosive environments is required.

- Q: How are steel products used in the manufacturing of electrical equipment?

- Steel products are commonly used in the manufacturing of electrical equipment for various purposes. They are used to create sturdy and reliable enclosures or casings, providing protection for sensitive components inside the equipment. Steel is also used to manufacture structural components, such as brackets and frames, which provide support and stability to the electrical equipment. Additionally, steel is often utilized in manufacturing electrical connectors, terminals, and conductive parts due to its high conductivity and durability. Overall, steel products play a crucial role in enhancing the performance, durability, and safety of electrical equipment.

- Q: What are the uses of steel in the construction of airports?

- Steel is widely used in the construction of airports due to its strength, durability, and versatility. It is used to create the structural framework of airport terminals, hangars, and control towers, providing the necessary support for the entire infrastructure. Additionally, steel is utilized in the construction of runways, taxiways, and aprons, as it can withstand heavy loads and resist wear and tear caused by aircraft movements. Moreover, steel is used in the fabrication of security fencing, gates, and barriers, ensuring the safety and security of the airport premises. Overall, steel plays a vital role in constructing airports by providing the necessary strength, durability, and security required for such complex structures.

- Q: What are the common uses of steel angles?

- Steel angles are commonly used in construction and engineering applications. They are often used as structural supports, providing stability and strength to various structures such as buildings, bridges, and towers. Steel angles are also used in the fabrication of frames, brackets, and reinforcements for machinery and equipment. Additionally, they are frequently utilized in the manufacturing of furniture, shelving units, and other metal-based products.

- Q: What are the different types of steel bridges and structures available?

- There are several types of steel bridges and structures available, including truss bridges, arch bridges, suspension bridges, cable-stayed bridges, and beam bridges. Truss bridges feature a framework of connected triangular elements, while arch bridges have a curved design that carries the load through compression. Suspension bridges are supported by cables hung from tall towers, and cable-stayed bridges have cables attached directly to the supporting towers. Beam bridges are the simplest type, consisting of beams supported by piers or abutments. These various designs offer different advantages and are chosen based on factors such as span length, site conditions, and aesthetic preferences.

- Q: How are steel products used in the construction of high-rise buildings?

- Steel products are used extensively in the construction of high-rise buildings due to their strength, durability, and versatility. They are commonly used for structural elements such as beams, columns, and frames, providing the necessary support and stability to withstand the weight and forces experienced by tall buildings. Additionally, steel is also used for cladding, roofing, and other architectural features, offering aesthetic appeal and functionality. Overall, steel's superior properties make it an ideal material for constructing safe and efficient high-rise buildings.

- Q: What are the properties of alloy steel for high-temperature applications?

- Alloy steel for high-temperature applications possesses several properties that make it suitable for such conditions. These properties include excellent strength, resistance to oxidation and corrosion, high thermal stability, and good creep resistance. Alloy steel also exhibits good mechanical properties, such as high tensile strength and toughness, which allow it to withstand the elevated temperatures and stresses experienced in high-temperature environments. Additionally, alloy steel can maintain its structural integrity even at extreme temperatures, making it a reliable choice for applications that involve exposure to heat and harsh conditions.

Send your message to us

AISI316 Stainless Steel Shot Ball for Grinding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords