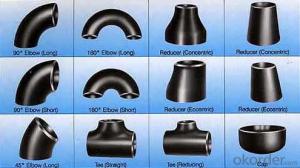

CARBON STEEL PIPE FITTING TEE BEND ELBOW FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: What are the common applications of steel pipes in the oil and gas industry?

- Steel pipes are commonly used in the oil and gas industry for various applications such as drilling, transportation of oil and gas, and pipeline construction. They provide strength, durability, and resistance to corrosion, making them suitable for carrying fluids under high pressure and in harsh environments. Steel pipes also facilitate efficient extraction, production, and distribution of oil and gas resources across vast distances.

- Q: What are the different end finishes available for steel pipes?

- Some of the different end finishes available for steel pipes include plain ends, beveled ends, threaded ends, grooved ends, and flanged ends.

- Q: What is the difference between ERW and SAW steel pipes?

- ERW (Electric Resistance Welded) steel pipes are manufactured by rolling metal sheets and then welding the seams using high-frequency electrical currents. SAW (Submerged Arc Welded) steel pipes, on the other hand, are formed by welding the seams using a submerged arc welding process. The main difference between the two lies in the welding method and the resulting quality of the weld. ERW pipes tend to have a smoother and more consistent weld, while SAW pipes have a slightly rougher weld due to the submerged arc process. Additionally, SAW pipes are generally used for larger diameters and thicker walls, while ERW pipes are commonly used for smaller diameters and thinner walls.

- Q: How are steel pipes used in the manufacturing of oil refineries?

- Steel pipes are used in oil refineries for a variety of purposes, including transporting crude oil and other fluids, as well as for structural applications. They are commonly used for piping systems, carrying process fluids such as oil, gas, and water, throughout the refinery. Additionally, steel pipes are used to handle corrosive and high-pressure environments, making them essential for the safe and efficient operation of oil refineries.

- Q: How are steel pipes used in oil and gas industry?

- Steel pipes are extensively used in the oil and gas industry for various purposes such as drilling, production, transportation, and refining. They are primarily used for the extraction of oil and gas from the ground, as well as for the transportation of these resources over long distances. Steel pipes are also utilized in the construction of storage tanks, refineries, and offshore drilling platforms. Their strength, durability, and resistance to corrosion make them ideal for withstanding the harsh conditions encountered in the oil and gas industry.

- Q: How do steel pipes handle expansion and contraction?

- Steel pipes handle expansion and contraction by allowing the material to expand and contract freely due to their inherent flexibility and elasticity. This prevents the pipes from experiencing excessive stress or damage, ensuring their durability and structural integrity.

- Q: Is the diameter of the steel tube indicated by the outer diameter by the wall thickness or by the inside diameter by the wall thickness?

- For seamless steel pipes or nonferrous metal pipes, the outer diameter * wall thickness shall be marked".For example, 108 x 4 phi, Phi can be omitted. Some steel tubes in China, ISO and Japan adopt wall thickness to indicate the thickness of steel pipe. The method for the specification of such steel tubes is pipe outer diameter * wall thickness. For example, Phi 60.5 * 3.8.

- Q: How are steel pipes used in the construction of oil refineries?

- Steel pipes are extensively used in the construction of oil refineries as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as transporting crude oil, refined products, and various chemicals within the refinery. They are also utilized in the construction of the refinery's infrastructure, including the fabrication of storage tanks, process equipment, and piping systems that connect different units and sections of the facility. Overall, steel pipes play a crucial role in maintaining the integrity and efficiency of oil refineries.

- Q: What are the different types of steel pipe supports for offshore platforms?

- There are several different types of steel pipe supports used for offshore platforms, including pipe racks, pipe clamps, pipe hangers, and pipe saddles. Pipe racks are used to support multiple pipes and provide a structure for them to rest on. Pipe clamps are used to secure individual pipes to structures or walls. Pipe hangers are used to suspend pipes from overhead structures, while pipe saddles are used to support pipes on horizontal surfaces. These different types of supports are designed to ensure the stability and integrity of the pipes in offshore environments.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes can be used for oil refineries. Steel pipes are commonly used in oil refineries due to their durability, high strength, and resistance to corrosion, making them suitable for transporting crude oil and refined products under high pressure and harsh conditions.

Send your message to us

CARBON STEEL PIPE FITTING TEE BEND ELBOW FITTINGS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords