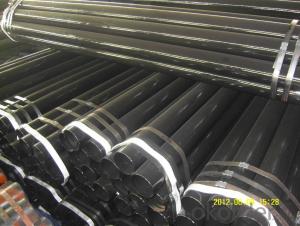

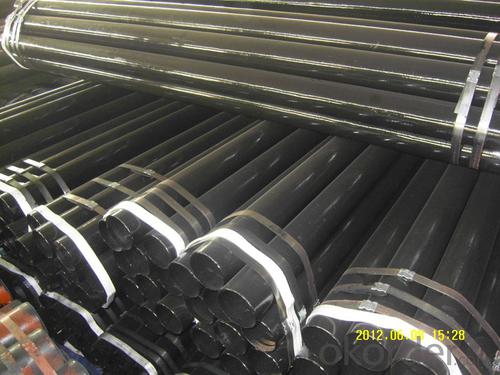

Carbon seamless steel pipe A106Gr.B with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Thickness: | 1 - 40 mm,1mm-40mm | Section Shape: | Round | Outer Diameter: | 1 - 813 mm |

| Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Boiler Pipe |

| Technique: | Cold Rolled | Certification: | CE | Surface Treatment: | Black Coated |

| Special Pipe: | EMT Pipe | Alloy Or Not: | Non-alloy | Type: | Seamless steel pipe |

| material: | A106Gr.B | Usage: | Boiler pipe | Chemical Compostion: | low carbon Steel Pipe |

| Grade: | 10#,20#,A53(A,B),A106(B,C),10#-45#,A53-A369 | Standard: | ASTM A106-2006,ASTM A53-2007,ASTM |

Packaging & Delivery

| Packaging Detail: | 1) in bundles 2Plastic Caps,Beveled ,or as the requirements of the customers 3) as the requirements of the customers |

| Delivery Detail: | Min within 10 days,or as the customer needs |

Specifications

Carbon Steel Pipe seamless steel pipe A106Gr.B

1)out diameter:6-820mm

2)thk:1-56mm

3)length: 5-6M 11.8M

- Q: What is the difference between internal and external coating for steel pipes?

- Internal coating for steel pipes refers to the application of a protective layer on the inner surface of the pipe to prevent corrosion and increase durability. This coating is designed to withstand the flow of fluids or gases through the pipe, ensuring the integrity of the material and minimizing the risk of contamination. On the other hand, external coating for steel pipes involves applying a protective layer on the outer surface of the pipe to safeguard it from environmental factors such as moisture, chemicals, or mechanical damage. This coating acts as a barrier, shielding the pipe from corrosion and extending its lifespan. In summary, internal coating focuses on protecting the inner surface of the steel pipe, while external coating aims to safeguard the outer surface. Both coatings are crucial for ensuring the longevity and reliability of steel pipes in various applications.

- Q: Can steel pipes be used for underground stormwater systems?

- Indeed, underground stormwater systems can utilize steel pipes. Renowned for their resilience and robustness, steel pipes are apt for enduring the pressure and burden of such systems. Furthermore, steel pipes possess remarkable resistance against corrosion, a crucial attribute when handling stormwater potentially laden with diverse pollutants. Nevertheless, it is imperative to adequately coat and safeguard the steel pipes to avert any potential corrosion or harm over time. Routine maintenance and inspections should also be undertaken to guarantee the integrity of the steel pipes and the overall efficacy of the underground stormwater system.

- Q: How to identify stainless steel pipe and steel pipe?

- Steel pipe according to the production method can be divided into two categories: seamless steel pipe and pipe joints, pipe joints as welded steel pipe.1. seamless steel tube according to the production methods can be divided into: hot-rolled seamless pipe, cold drawn tube, precision steel tube, heat expansion tube, cold spinning tube and extrusion tube.Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).Bundled steel pipe2. welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square, flat) pipe.

- Q: Seamless steel pipe is how to do it?

- 1. seamless steel tubes for structural purposes (GB/T8162-1999) are seamless steel tubes for general structural and mechanical construction.2. seamless steel pipe for fluid transportation (GB/T8163-1999) is used to transport water, oil, gas and other fluids of general seamless steel pipe.3. seamless steel tubes for low and medium pressure boiler (GB3087-1999) is used in the manufacture of various structures of low and medium pressure boiler superheated steam pipe, superheated steam pipe, boiling water pipe and boiler flue tube, pipe and brick arch tubes of high quality carbon steel hot rolling and cold drawing (rolling) seamless steel tube.4. high pressure boiler seamless steel tube (GB5310-1995) is used for the manufacture of high-pressure and above the pressure of water boiler heating surface for high-quality carbon steel, alloy steel and stainless steel heat-resistant seamless steel pipe.5. high pressure seamless steel tube (GB6479-2000) for chemical fertilizer equipment is a kind of high quality carbon structural steel and alloy steel seamless pipe for chemical equipment and pipes of working temperature of -40~400 DEG C and working pressure of 10~30Ma.6. seamless steel tubes for petroleum cracking (GB9948-88) are tubes, heat exchangers and seamless steel tubes used in refineries.

- Q: How are steel pipes inspected for defects?

- Steel pipes are inspected for defects using various methods, including visual inspection, ultrasonic testing, magnetic particle inspection, dye penetrant testing, and radiographic examination. These techniques help identify any cracks, corrosion, or other defects in the pipes to ensure their structural integrity and prevent any potential hazards or failures.

- Q: What are the different wall thicknesses available for steel pipes?

- The different wall thicknesses available for steel pipes vary depending on the specific application and requirements. Common wall thicknesses for steel pipes include standard, extra strong, and double extra strong, with each thickness offering different levels of strength and durability.

- Q: What are the different standards for steel pipes?

- There are several different standards for steel pipes, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), and ASME (American Society of Mechanical Engineers). These standards specify the requirements for various aspects of steel pipes, such as their dimensions, chemical composition, mechanical properties, and testing procedures. These standards ensure that steel pipes meet the necessary quality and safety standards for their intended applications.

- Q: How do you calculate the pipe flow velocity for steel pipes?

- To determine the velocity of flow in steel pipes, two equations can be utilized: Manning's formula or the Darcy-Weisbach equation. 1. Manning's formula, commonly applied to open channel flow but also suitable for partially filled pipes, calculates velocity based on the pipe's hydraulic radius, slope, and Manning's roughness coefficient. The formula is as follows: Velocity (V) = (1.486/n) * (R^2/3) * (S^1/2) In this formula: - V represents the velocity - n denotes the Manning's roughness coefficient (obtainable from reference tables) - R signifies the hydraulic radius (cross-sectional area divided by wetted perimeter) - S indicates the slope of the energy grade line 2. The Darcy-Weisbach equation, widely used for pipe flow calculations, derives velocity from the pipe's diameter, roughness coefficient, and head loss due to friction. The equation is as follows: Velocity (V) = (2 * g * hL)^0.5 In this equation: - V represents the velocity - g stands for the acceleration due to gravity (approximately 9.81 m/s^2) - hL refers to the head loss caused by friction, which can be calculated using the Darcy-Weisbach equation: hL = (f * L * V^2) / (2 * g * D) In this equation: - f denotes the Darcy friction factor (dependent on the Reynolds number and pipe roughness) - L represents the length of the pipe - D indicates the diameter of the pipe Both formulas necessitate input parameters such as pipe dimensions, roughness coefficients, and slope. These parameters can be obtained from engineering references or pipe manufacturer specifications. It is essential to note that these formulas provide approximate values and may require iterations or adjustments for precise outcomes.

- Q: What are the different methods of protecting steel pipes from corrosion?

- There are several methods of protecting steel pipes from corrosion, including: 1. Coatings: Applying protective coatings such as epoxy, polyethylene, or zinc to the surface of the steel pipes can create a barrier against corrosive elements. 2. Cathodic Protection: This method involves installing sacrificial anodes or impressed current systems to provide a protective current that counteracts the corrosion process. 3. Corrosion Inhibitors: Adding chemicals or inhibitors to the fluid or environment surrounding the pipes can reduce the rate of corrosion. 4. Internal Linings: Applying internal linings made of resin, cement, or other materials can protect the inner surface of the pipes from corrosion caused by the transported fluid. 5. Design Considerations: Implementing proper design practices like avoiding sharp bends and crevices, ensuring proper drainage, and using corrosion-resistant alloys can help prevent corrosion in steel pipes.

- Q: There are multiple welded galvanized steel pipe outer diameter 108mm wall thickness 4mm length of 6 meters

- Formula for calculating weight of welded steel pipe:Kg/m= (outside diameter mm-, wall thickness mm) * wall thickness mm*0.02466= (108-4) *4*0.02466=10.26 kg / MBecause of galvanizing, the weight is heavier than that of ordinary welded pipe 3%~6%.Therefore, the length of 6 meters galvanized steel pipe weighs about 10.26*6*1.06=65 kilograms

Send your message to us

Carbon seamless steel pipe A106Gr.B with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords