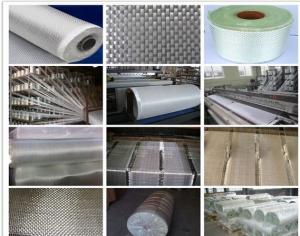

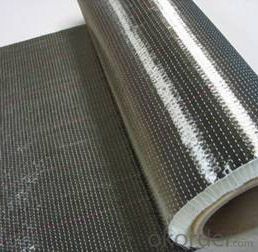

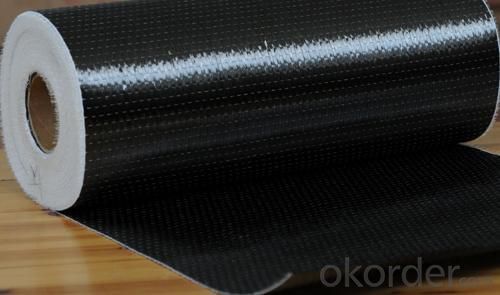

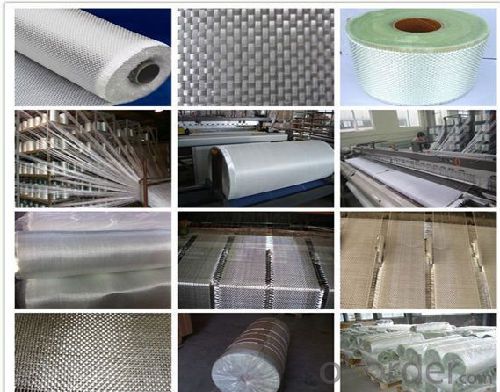

Carbon Fiber Weaving Fabric Reinforced Fibreglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

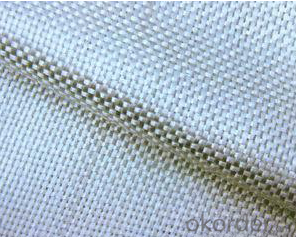

Weave:Plain,Twill,Satin,Multiaxial,UD

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Are fiberglass fabrics suitable for use in the mining industry?

- The mining industry finds fiberglass fabrics to be a suitable choice. These fabrics are renowned for their exceptional strength and durability, making them an ideal option for demanding tasks like mining. They exhibit impressive resistance against chemicals, abrasion, and high temperatures, which are prevalent in mining operations. Moreover, fiberglass fabrics offer the advantage of being lightweight, facilitating their handling and installation in mining equipment and structures. Their low thermal conductivity also aids in reducing heat transfer within mining environments, safeguarding workers and equipment from excessive heat. Additionally, fiberglass fabrics possess excellent electrical insulation properties, a crucial aspect in mining operations where electrical hazards pose a risk. Furthermore, they are non-combustible, contributing to enhanced safety in potentially hazardous mining environments. Furthermore, fiberglass fabrics can be produced in various forms, including woven, non-woven, and composite materials with other fibers or resins. This versatility permits customization to meet specific requirements of the mining industry, such as flame resistance, chemical resistance, or increased strength. In conclusion, fiberglass fabrics are highly suitable for the mining industry due to their strength, durability, resistance to chemicals and high temperatures, lightweight nature, electrical insulation properties, and customization options. They offer a reliable and safe solution for diverse mining applications, ensuring the efficiency and safety of mining operations.

- Q: How does fiberglass fabric perform in chemical environments?

- Fiberglass fabric exhibits remarkable performance in chemical settings, renowned for its ability to resist a wide array of chemicals, including acids, alkalis, solvents, and oils. This resistance is primarily attributed to the composition of the fabric, which comprises glass fibers coated or impregnated with a chemical-resistant resin. Due to its chemical resistance, fiberglass fabric is a highly suitable option for applications in various industries such as chemical processing, petrochemicals, pharmaceuticals, and food processing. It can be employed in the form of curtains, gaskets, seals, and linings to safeguard equipment and structures from corrosive chemicals. Moreover, fiberglass fabric's ability to withstand chemical exposure extends to elevated temperatures. It can endure continuous operating temperatures of up to 550°C (1022°F) without significant deterioration. This quality renders it appropriate for applications that involve both high temperatures and chemical environments, such as thermal insulation and fire protection systems. Aside from its chemical resistance, fiberglass fabric possesses other advantageous properties. It is lightweight, durable, and boasts exceptional mechanical strength. Furthermore, it is non-flammable, providing an additional layer of safety in chemical environments where fire hazards are a concern. Nevertheless, despite its exceptional performance in chemical environments, it is essential to acknowledge that fiberglass fabric may still be vulnerable to certain highly reactive chemicals or extreme conditions. Therefore, consulting with manufacturers or experts is crucial to ascertain the suitability of fiberglass fabric for specific chemical environments and applications.

- Q: Can fiberglass fabric be used for insulation in cold storage facilities?

- Certainly, cold storage facilities can utilize fiberglass fabric as insulation. Renowned for its remarkable thermal insulation properties, fiberglass fabric proves to be a perfect selection for insulating cold storage facilities. It exhibits utmost effectiveness in impeding heat transfer, thereby aiding in maintaining the desired temperature within the facility. Furthermore, fiberglass fabric showcases resilience against moisture, mold, and mildew, prevailing issues in cold storage environments. This renders it an enduring and enduring option for insulation. Additionally, fiberglass fabric boasts effortless installation and adaptability to accommodate diverse shapes and sizes, guaranteeing comprehensive coverage and insulation throughout the facility.

- Q: Waterproof method of glass fiber cloth for toilet

- Root canal sealant seal, cement smooth foot slip, waterproof paint brush when sticking glass cloth reinforced layer 1~2 layer. Similar measures near the floor drain.

- Q: How does fiberglass fabric perform in peel strength?

- Fiberglass fabric is known for its exceptional peel strength. Thanks to its inherent strength and durability, fiberglass can withstand substantial pulling forces without delaminating or tearing. The bond between the fiberglass fabric and the substrate is typically strong, resulting in high peel strength values. These qualities make fiberglass fabric an ideal choice for industries that require strong adhesion and resistance to peeling, like composite manufacturing, aerospace, automotive, and construction. Moreover, the flexibility and lightweight nature of fiberglass fabric contribute to its overall peel strength performance, enabling it to conform to different surfaces and maintain its integrity when subjected to stress.

- Q: How does fiberglass fabric perform in electrical conductivity?

- Fiberglass fabric possesses outstanding electrical insulation properties, rendering it an inadequate conductor of electricity. This is due to the presence of non-conductive, fine glass fibers in fiberglass, which restrict the passage of electrical current. Consequently, fiberglass fabric finds widespread use in electrical insulation applications, effectively mitigating the potential hazards of electric shocks or short circuits. Moreover, fiberglass fabric exhibits resistance to elevated temperatures, chemicals, and UV radiation, thus bolstering its effectiveness as an electrical insulator. All in all, fiberglass fabric emerges as a dependable material in terms of electrical conductivity, delivering exceptional insulation capabilities suitable for a diverse array of applications.

- Q: Is fiberglass fabric resistant to salt spray in coastal areas?

- Yes, fiberglass fabric is generally resistant to salt spray in coastal areas. The non-corrosive properties of fiberglass make it highly durable and suitable for withstanding the harsh effects of saltwater and salt air.

- Q: What is the difference between glass fiber plain cloth and glass fiber grid cloth? What are the specifications and specifications of plain cloth and square cloth?

- The plaid is large in number. The general is in heavy and wide points. At present, the most common grams are from 200 grams per gram to 1600 grams per square meter. The common width ranges from 50 millimeters to 3000 millimeters. Mainly controlled by the design of textile machines. The combination of warp and weft will inke weight different adjustment. Roving is heavy on the need to use the greater the number, the filament diameter or line density (Tex number) will follow the larger.

- Q: Difference between glass fiber felt and glass fiber cloth

- Glass fiber mesh is a kind of glass fiber cloth.

- Q: Can fiberglass fabrics be used for insulation in HVAC systems?

- Indeed, insulation in HVAC systems can utilize fiberglass fabrics. The preference for fiberglass as an insulation material in HVAC systems stems from its exceptional thermal characteristics. Its low thermal conductivity enables it to effectively impede heat transfer. Fiberglass fabrics are typically employed to encase air ducts, pipes, and other components in HVAC systems to prevent heat loss or gain. Aside from its thermal efficiency, fiberglass fabrics possess other advantageous properties that render them suitable for insulation purposes. They are lightweight, flexible, and simple to install, making them a convenient option for HVAC insulation. Additionally, fiberglass fabrics exhibit resistance to moisture, mold, and mildew, thus contributing to the maintenance of satisfactory indoor air quality. Moreover, fiberglass fabrics boast outstanding fire-resistant qualities. They are non-combustible and do not emit toxic gases when exposed to high temperatures. Consequently, fiberglass fabrics constitute a safe choice for insulation in HVAC systems. All in all, the utilization of fiberglass fabrics for insulation in HVAC systems proves to be highly effective due to their thermal efficiency, ease of installation, resistance to moisture, and fire safety.

Send your message to us

Carbon Fiber Weaving Fabric Reinforced Fibreglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords