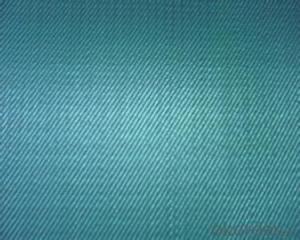

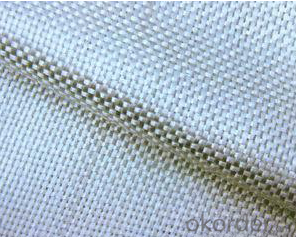

Carbon Fiber Weaving Fabric Reinforced Fibreglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

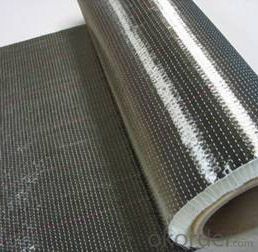

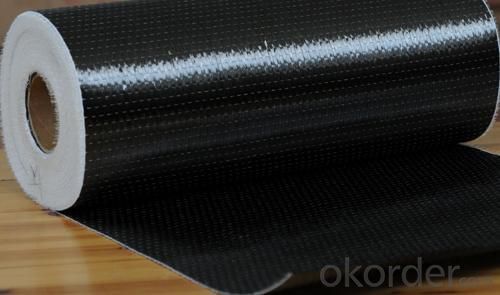

Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Main Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

Weave:Plain,Twill,Satin,Multiaxial,UD

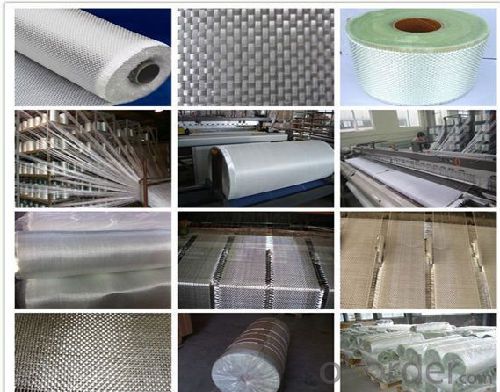

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What are the different fiberglass fabric weaves for high strength applications?

- There are multiple fiberglass fabric weaves commonly utilized for high strength applications, including plain weave, twill weave, satin weave, and leno weave. 1. Plain weave: This weave pattern is the most fundamental and widely used. It involves an over-under pattern, with each warp yarn passing over and under each weft yarn. Plain weave fabrics offer exceptional strength and dimensional stability, making them appropriate for a wide range of high strength applications. 2. Twill weave: Twill weave is characterized by a diagonal pattern formed by the interlacing of warp and weft yarns. This weave is renowned for its strength and durability. Twill weave fabrics possess good drapability, making them ideal for applications requiring flexibility and resistance to wrinkling. 3. Satin weave: Satin weave is identified by long floats, where the warp or weft yarns skip over multiple yarns in the opposite direction. This creates a smooth and glossy surface. Satin weave fabrics boast excellent strength and are commonly used in applications desiring a high-quality finish, such as aerospace components and luxury goods. 4. Leno weave: Leno weave is a distinctive pattern that involves twisting adjacent warp yarns around each weft yarn. This creates a stable and open structure with good strength and stability. Leno weave fabrics find common use in high strength applications where breathability and lightness are crucial, such as filtration systems and composites. These various fiberglass fabric weaves offer different levels of strength, flexibility, and durability, enabling manufacturers to select the most suitable weave for their specific high strength applications.

- Q: Can fiberglass fabric be used for conveyor belts?

- Conveyor belts can indeed utilize fiberglass fabric. Renowned for its remarkable strength and ability to withstand heat, chemicals, and abrasion, fiberglass fabric proves itself suitable for diverse industrial uses, including conveyor belts. Given its capacity to endure extreme temperatures and maintain superb dimensional stability, fiberglass fabric becomes indispensable in conveyor belt systems that accommodate ceaseless motion and hefty loads. Furthermore, its minimal coefficient of friction facilitates seamless and efficient material handling. In summary, fiberglass fabric emerges as a dependable and robust option for conveyor belts in manufacturing, mining, and food processing industries.

- Q: What type of thread is used for sewing fiberglass fabric?

- Polyester thread, referred to as the commonly used thread for sewing fiberglass fabric, is specifically engineered to possess strength and durability. This makes it well-suited for stitching heavy and resilient materials such as fiberglass. With its elevated tensile strength, it effectively withstands abrasion, a crucial quality when handling stiff and abrasive fiberglass fabric. Moreover, polyester thread exhibits resistance to both UV rays and chemicals, rendering it perfect for outdoor and industrial applications that frequently involve fiberglass fabric.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- Fiberglass fabric is indeed suitable as insulation in steam systems. Its exceptional thermal insulation properties and ability to withstand high temperatures make it a favored option. By effectively capturing the steam's heat, it prevents any loss of heat and enhances energy efficiency in the system. Moreover, fiberglass fabric's lightweight, flexible, and effortless installation process make it a convenient choice for insulating steam pipes and equipment. Its non-combustible nature also ensures safety in steam systems. All in all, fiberglass fabric is a dependable and efficient insulation material for steam systems.

- Q: When decorating, how can the waterproof of kitchen and toilet be checked and accepted?

- Do closed water test. The kitchen and bathroom were filled with water up to 20cm high. For 24 to 48 hours of closed water test, the water level was observed to drop significantly and to see if there was any water seeping from the ground floor. For the light wall, the water is detected to see if there is water leakage on the back.

- Q: How does fiberglass fabric perform in water repellency?

- Fiberglass fabric performs exceptionally well in terms of water repellency. The fabric is made from woven glass fibers, which are naturally hydrophobic in nature. This means that water molecules are unable to penetrate the fabric easily, resulting in excellent resistance to water absorption. The hydrophobic properties of fiberglass fabric make it ideal for applications where water repellency is crucial, such as in the production of outdoor clothing, tents, and boat covers. When exposed to water, the fabric remains relatively dry and does not become heavy or waterlogged. Additionally, the construction of fiberglass fabric allows it to maintain its water repellency over time. The fabric does not easily lose its hydrophobic properties, even after repeated exposure to water or washing. This durability makes fiberglass fabric a reliable choice for applications where long-term water resistance is required. However, it is important to note that while fiberglass fabric is highly resistant to water absorption, it is not completely waterproof. In extreme conditions, such as heavy rain or prolonged submersion, some water may eventually seep through the fabric. Nonetheless, fiberglass fabric still outperforms many other materials in terms of water repellency and remains a popular choice in various industries.

- Q: Is fiberglass fabric resistant to chemicals used in construction industry?

- Yes, fiberglass fabric is generally resistant to the chemicals commonly used in the construction industry. It is known for its excellent chemical resistance properties, making it a popular choice for various construction applications.

- Q: Are fiberglass fabrics biodegradable?

- No, fiberglass fabrics are not biodegradable.

- Q: Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. Fiberglass fabric is known for its durability, strength, and resistance to various weather conditions, making it an excellent choice for outdoor applications like tents and awnings. It is lightweight, yet provides excellent protection from the elements such as rain and wind. Additionally, fiberglass fabric has good UV resistance, which helps to prevent fading and damage from prolonged exposure to the sun. Its inherent fire-resistance properties also make it a safe choice for outdoor structures. Overall, fiberglass fabric is a suitable material for making tents and awnings as it offers a combination of strength, durability, and weather resistance necessary for these applications.

- Q: How is fiberglass fabric used in the production of thermal gloves?

- Fiberglass fabric is commonly used in the production of thermal gloves due to its excellent insulation properties. This type of fabric is made by weaving together fine strands of glass fibers, resulting in a material that is lightweight, durable, and has high heat resistance. In the production of thermal gloves, fiberglass fabric is typically used as an inner lining or as an additional layer to enhance the insulation capabilities of the gloves. This fabric acts as a barrier between the cold external environment and the hand, preventing heat loss and keeping the hands warm. The glass fibers in the fabric are excellent thermal insulators, meaning they do not conduct heat well. This property helps to trap the body heat generated by the hand, creating a layer of warmth and effectively insulating the hands from the cold. Additionally, fiberglass fabric is resistant to moisture, which is particularly useful in thermal gloves as it helps to keep the hands dry and prevents the growth of bacteria or mold. This makes the gloves more comfortable to wear for extended periods and reduces the risk of skin irritation or infections. Furthermore, fiberglass fabric is known for its strength and durability. This makes it ideal for use in thermal gloves, as it can withstand frequent use and resist wear and tear. It also helps to maintain the shape and structure of the gloves, ensuring a longer lifespan. In summary, fiberglass fabric is used in the production of thermal gloves due to its excellent insulation properties, moisture resistance, and durability. It helps to keep the hands warm, dry, and protected from the cold, making it an essential component in the manufacturing process.

Send your message to us

Carbon Fiber Weaving Fabric Reinforced Fibreglass Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000KG kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords