Cantilever-Type Bucket-Wheel Stacker Reclaimer,Stacker and Reclaimer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

Cantilever bucket wheel stacker reclaimer is a kind of high efficiency and continuous operation of large handling equipment for bulk materials, mainly used in power, metallurgy, coal, building materials and chemical industry, such as coal and ore storage field.

The arm length of this cantilever bucket wheel stacker reclaimer is 20-60m, and the capacity of stacker and reclaimer is 100-10000t/h. This equipment is widely used in strip type raw material yard.

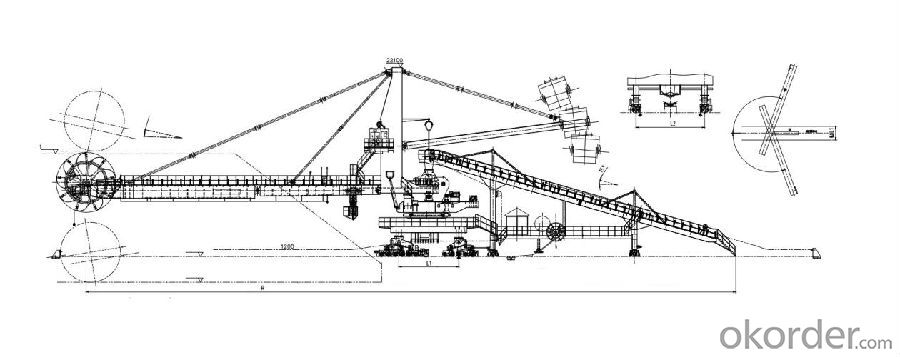

Overall Drawing

Technical Parameters

Model | Unit | DQL200/450.20 | DQL300/600.25 | DQL800/1200.30 | DQL1500/1500.35 | DQL1800/3200.40 | DQL1500/1500.45 | DQL2500/1500.55 | QL3000.45 | QL8000.50 | |

Production Capacity | Stacking | t/h | 450 | 600 | 800 | 1500 | 1800 | 1500 | 1500 | / | / |

Reclaiming | t/h | 200 | 300 | 1200 | 1500 | 3200 | 1500 | 2400 | 3000 | 8000 | |

Stacking Height | Upper Track | m | 8~15 | ||||||||

Lower Track | m | 0.5~2.5 | |||||||||

Material Characteristics | Applicable Materials | Coal, coke, limestone, bauxite, iron ore, pellets, clay and other bulk materials | |||||||||

Density | t/m³ | 0.5~2.5 | |||||||||

Granularity | mm | 0~300 | |||||||||

Bucket Wheel Diameter | m | 3.3~10 | |||||||||

Slewing Mechanism | Radius | m | 20 | 25 | 30 | 35 | 40 | 45 | 55 | 45 | 50 |

Angle | ° | ±110 | |||||||||

Conveyor | Belt Width | mm | 650~2400 | ||||||||

Belt Speed | m/s | 1.25~5 | |||||||||

Travelling Speed | Working | m/min | 7 | ||||||||

Shunting | m/min | 30 | |||||||||

Span | m | 4.5 | 5 | 6 | 7 | 8 | 8 | 9 | 9 | 10 | |

Max. Wheel Pressure | KN | 250/300 | |||||||||

Steel Track | P50/Q80 | ||||||||||

Power Supply Mode | Cable Drum/Safety Trolley Line | ||||||||||

Communication Mode | Cable Drum/Safety Trolley Line /Wireless | ||||||||||

Control Mode | PLC Programme Control/Manual/Auto | ||||||||||

Feature

- Cantilever bucket wheel stacker reclaimer integrates lifting, transportation and mining functions into one and has high efficiency. The digging mechanism and the transport mechanism are organically combined, the former takes the material, the latter transport, and the two work at the same time.

- Low energy consumption. The belt conveyor with small resistance is adopted in the transportation of materials, and the rolling bearing is used in the slewing mechanism to reduce the power consumption.

- The service life of the cantilever bucket wheel stacker reclaimer is long, and the machine has small impact force from reclaimer, small wear and tear of gears, and wear resistant material used for bucket teeth, which can prolongs the service life.

- The equipment is easy to operate. PLC control is adopted to realize semi-automatic and automation of the work process. The 1/cos frequency control of motor speed is adopted in the cantilever slewing, so that the machine is in high efficiency.

- Cantilever bucket wheel stacker reclaimer adopts advanced design method, such as computer aided design, three-dimensional design and optimum design of steel structure, combined with the stacker reclaimer’s experience of design, and constantly sum up. In the design to achieve advanced technology and reasonable, so that the use of equipment are more reliable.

- The cantilever bucket wheel stacker reclaimer is guaranteed by advanced production equipment and process; for example, the steel pretreatment line ensures the quality and corrosion resistance of the products manufactured, the use of large milling boring machine improves the machining quality of large parts. The large structural parts are pre assembled in the factory, the driving parts are tested in the factory, and the rotating parts are made of mould.

Constitution

The Cantilever bucket wheel stacker reclaimer consists of bucket wheel mechanism, upper steel structure, boom conveyor, main machine ladder/walkway stairs and platform, luffing unit, travelling mechanism, portal, center chute, impact bracket, slew unit, central lubrication system, limit switch device, detection device, tripper car, ladder platform of tripper car, electrical house, electrical system, operator’s cabin and bracket, nameplate, counterweight assembly, dust suppression system, power cable reel device, control cable reel device, water cable reel device, slew deck, supporting pivot block, foundational layout and load etc.

The upper structure of main machine is an integral structure which consists of forearm frame, gate post, counterweight boom and front and rear tie rod , all parts will be connected by pin roll which fixed by snag gauge. Head part is hanged bucket wheel mechanism; the counterweight assembly on the rear part that can adjust the balance of upper structure. The upper structure is fixed on slew deck by supporting pivot block, the upper part of the supporting pivot block and the end part of the gate post will be hinged joint; and lower pivot support should be welded with the upper plane of slew deck. The complete upper structure can waggle around the support pivot point, Integral pitching of upper structure to be realized by the function of the hydraulic cylinder between the turntable and the gate post.The rotary driving device is fixed on the turntable, through the output shaft small gear of reducer to mess the big gear ring of the bearing’s lower half part which fixed on the bottom base ring to drive the superstructure to rotate around the center of rotation. The hinged support of the travelling mechanism and the portal adjusting ring will be assembled and welded on the site.

Portal adopts four-points supporting. The central transfer hopper is located on the rotary center line of the main machine, the upper open part of hopper is connected with the head part of coal falling hopper(during the tripper car is in stacking operation) and the gathering sill of cantilever belt conveyor which near the head roll; the lower open part of hopper is connected with buffer bracket.

The power supply of the cantilever bucket wheel stacker reclaimer adopts flat cable which will be winded on the machine by cable reel. The luffing hydraulic device of the main machine is fixed on the turntable. The water source device on the tripper car includes power, control cable reel, water cable reel, electric room and watering device.

FAQ

1. How to determine the radius of gyration and the angle of gyration of the cantilever bucket wheel stacker reclaimer?

- Considering the layout of the material yard and the size of the material heap, the material space can be covered to the maximum extent without interference in the equipment and the material yard.

2. How to determine the tail type of the cantilever bucket wheel stacker reclaimer, such as single tail car, double tail car?

- Considering the overall process of material delivery, such as through, turn back, shunt conditions, and then determine the most economical layout form according to user needs.

Send your message to us

Cantilever-Type Bucket-Wheel Stacker Reclaimer,Stacker and Reclaimer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords