Scraper-Type Circular Stockyard Reclaimer and Stacker,Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

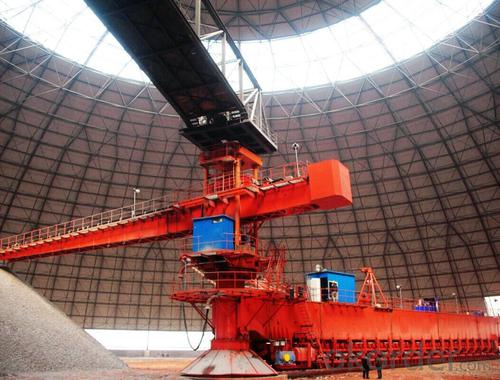

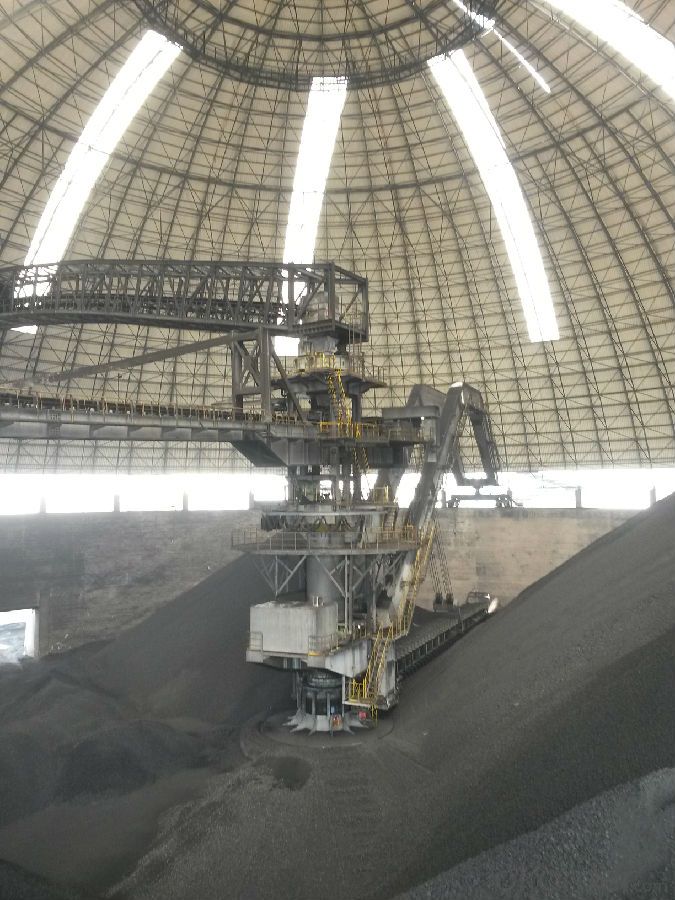

Scraper-type circular stockyard reclaimer and stacker is a pre-equalization equipment that adopt continuous synthetic stacking and whole section materials methods to reclaim and stack It’s mostly used to stack bulk materials such as limestone, which is useful in construction, coal, metallurgy, electricity, port industries. It’s applicable for indoor or hypaethral area where the bulk materials need to homogenize, store, transfer. Scraper-type circular stockyard reclaimer and stacker is capable of blending material pilling and blending material reclaiming simultaneously or respectively.

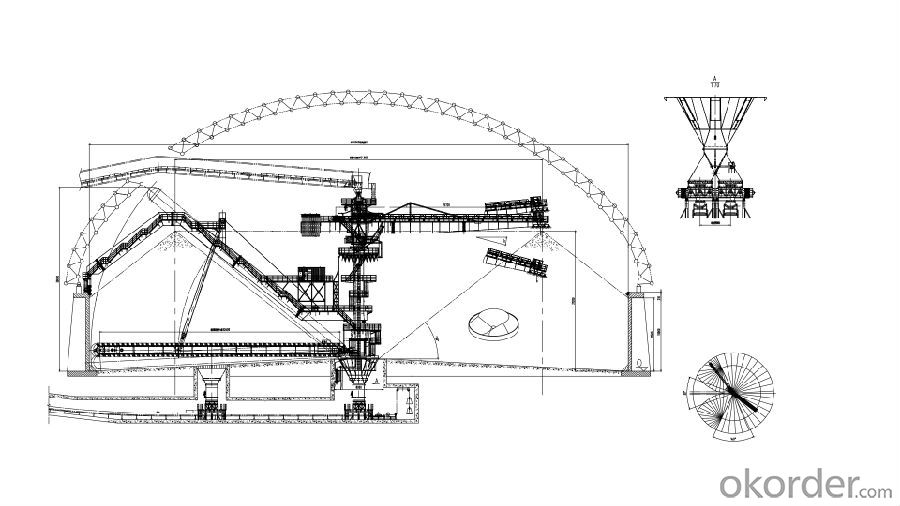

Scraper-type circular stockyard reclaimer and stackerhas three types: cantilever(Top pile side), gate type and bridge type.

According to operational environment, Scraper-type circular stockyard reclaimer and stacker is divided into 2 types: indoors and hypaethral inclined. The stockyard diameter ranges from Φ60~Φ120.

Scraper-type circular stockyard reclaimer and stacker has good equalization effect, large stockyard capacity, small occupy area, high-automatic and good environmental protection performance features.

Characteristic

The used stacker-reclaimer in round coal field is covered by the hemispherical surface of coal-storage tank. The operation range is concentrated on the rotary range, which can not be influenced by severe weather, for example, typhoon. In the meanwhile, it has a small range of raise dust. And then, it is limited in the fixed area. Thus, it can greatly solve the large-range pollution that caused by a large number of raise dust in the operation of the routine open-type bar-type coal field stacker and reclaimer for surroundings. It has a excellent appearance and environmental protection with a high comprehensive benefits. The structural feature of the equipment is that the stacker and claimer circles the central column to make a 360°circular motion. The Scraper-type circular stockyard reclaimer and stackerhas such following advantages, such as effective homogenization, large storage volume in stock yard, low covering area, high usage of site, high reliability and safety, high degree of automation, good environmental protection and etc.

Maintaining of hydraulic system

The operator should monitor the working condition of hydraulic system. Especially the operator should monitor the work stress and the traveling speed of executing mechanism. Before the hydraulic system is started, the operator should check the electromagnetic and all of the traveling mechanism whether if they are in the original condition. Whether if the oil level in fuel tank is normal. The operator can not damage the interlock device of the electric system. It is prohibited that the operator push the electric control valve by hands. When the hydraulic system is out of work, the operator should report the problem to the maintaining department or the manufacturer of the hydraulic system. And then, the failure cause should be analyzed and the operator should exclude the failure as soon as possible. The hydraulic equipment should often be kept clear, which aims to block all kinds of contaminant into the fuel tank. The following parts should be fastened once monthly, such as pipe joint, flange plate, tightening screw of hydraulic cylinder, bolt for fastening the cover, plummer block bearing of piston rod, adjusting screw for plummer block bearing on the work bench , travel switch, link stopper fixed screw and etc. The hydraulic system of low pressure can be fastened once at trimonthly. When the bolt is fastened, it must take balance tightening force. Also, it must reach the regulated tightening torque. In the normal period, it must be replaced when is has operated two years or all of sealing element parts should be replaced when the machine is stopped for heavy repairing. The hydraulic cylinder should be clean biyearly. And the fuel should be clean one time half a year. In terms of the manifolds, flexible tube, detachable tunnel should be detached and rinsed. The cleaning period of the manifolds, flexible tube, detachable tunnel should be in line with the working condition and pollution condition of hydraulic equipment. The filter element of the oil filter should be often changed.

Setch

Technical specification

Equipment Model | Unit | YG | YG | YG | YG | YG | YG | YG | YG | |||

Production capacity | Stack | 500~800 | 500~ | 500 | 800 | 1000 | 1000 | 1000 | ||||

Reclaim | 40~200 | 100~ | 40~

| 250~ | 400~ | 800~ | 1000~ | 1000~ | ||||

Proper of material | Suitable material | Coal,coke, limestone, bauxite , iron ore, pellet ore, clay and other bulk material | ||||||||||

Density | t/m³ | 0.5~2.5 | ||||||||||

Particle size | Mm | 0~300 | ||||||||||

Diameter of material yard | m | 60 | 78 | 80 | 90 | 95 | 100 | 110 | 120 | |||

Storage capacity | m³ | 15000 | 30000 | 34000 | 52000 | 60000 | 75000 | 86000 | 95000 | |||

Traveling speed | Reclaim | m/ | 0.2~2stepless speed regulate | |||||||||

Dispatching vehicle | m/ | 10 | ||||||||||

Slewing speed of reclaim | m/ | 0.01 | ||||||||||

Stack | Rotary | m/ | 0.01 | |||||||||

Various amplitude | 0.3~0.6 | |||||||||||

Max. Wheel load | 250/300 | |||||||||||

Recommended steel rail | P50/Q80/Q100 | |||||||||||

Power supply model | Cable drum/ safety sliding contact line | |||||||||||

Contact mode | Cable drum/ safety sliding contact line/wireless | |||||||||||

Control method | PLC Control, manual operation,single move | |||||||||||

Model demonstration:YG(1)(2)(3)

YG- category code:circular stockyard stacker reclaimer

(1)reclaiming capacity(t/h)

(2)stacking capacity(t/h)

(3)stockyard capacity(m)

FAQ

Whether if the operation range of equipment can cover the stack yard totally? Whether if the stacking and reclaiming can be operated at the same time?

Combining with the characteristic of scraper-type circular stockyard reclaimer and stacker, no matter the belt of upper cantilever stacking or the bottom scraper reclaiming system is two independent system. Thus, it can not be influenced no matter it is used independently or it is in integration of operation.

Whether if the Scraper-type circular stockyard reclaimer and stackercan be transported on land route without obstacle?

In consideration of different despatch methods, the disassemble design has been designed in the course of design which can insure the side cantilever stacker can be transported successfully in line with kinds of limitation on the land route.

Whether the equipment is carried with the spare parts or the vulnerable parts when it is left the factory?

According to the characteristics of the equipment, the parts with high frequency and easy wear are randomly attached with spare parts. At the same time, the list of vulnerable parts is provided for the owner to choose. And the cost is greatly affected. The spare parts need to be signed with the owner to supply the commercial terms

How long will the equipment is maintained?

In line with different maintenance period and the distinguished of methods, it is different. You can refer to the equipment maintenance instruction.

Send your message to us

Scraper-Type Circular Stockyard Reclaimer and Stacker,Mining Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords