Gantry Bucket Wheel Stacker Reclaimer,Stacker and Reclaimer, Bulk Transportation Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Gantry Bucket Wheel Stacker Reclaimer is a large loading and unloading equipment for continuous stacking bulk materials, the whole equipment of Gantry Bucket Wheel Stacker Reclaimer is connected by gantry main frame structure. It is suitable for large thermal power plant, industrial and mining enterprises, bulk material storage yard of port.

The track spacing of the Gantry Bucket Wheel Stacker Reclaimer is usually more than 35 meters. There are two ways to change the loading and unloading of the tail car, one method is to change the position of the front part of the tail truck relative to the movable beam by using the ring installed at one end of the movable beam; the other is to change the position of the tail truck relative to the movable beam by using the self or the electric push rod of tail truck, when the height of the movable beam is changed, the front part of the tail vehicle moves along with the movable beam.

Gantry Bucket Wheel Stacker Reclaimer has the characteristics of high efficiency, easy operation and so on. The height of the movable beam can be adjusted up and down to suit the different height of the stacker during mining. When the circle ring is installed at one end of the movable beam to change the height of the front part of the tail truck relative to the movable beam, the stacker and reclaimer are all used belt conveyors what inside the movable beam. The belt conveyor in the movable beam is three, the upper part is two, and the lower part is one, the three belt conveyor can complete the process of stacker and reclaimer. The belt conveyor on the Gantry Bucket Wheel Stacker Reclaimer can be arranged in three ways: 1. Three belt conveyors are used in the movable beam, and the stacker is operated when the two belt conveyors are used, and the material is taken when all three are used; 2. One belt in the movable beam is used for fetching materials, and one belt is used at the lower part of the main beam for stacking; 3. One belt can stack and reclaim materials which in the movable beam.

Our company's gantry Bucket Wheel Stacker Reclaimer, its rail span range of 20-60m, reclaimer capacity range of 150-2500t/h, stacking capacity range of 300-3000t/h.

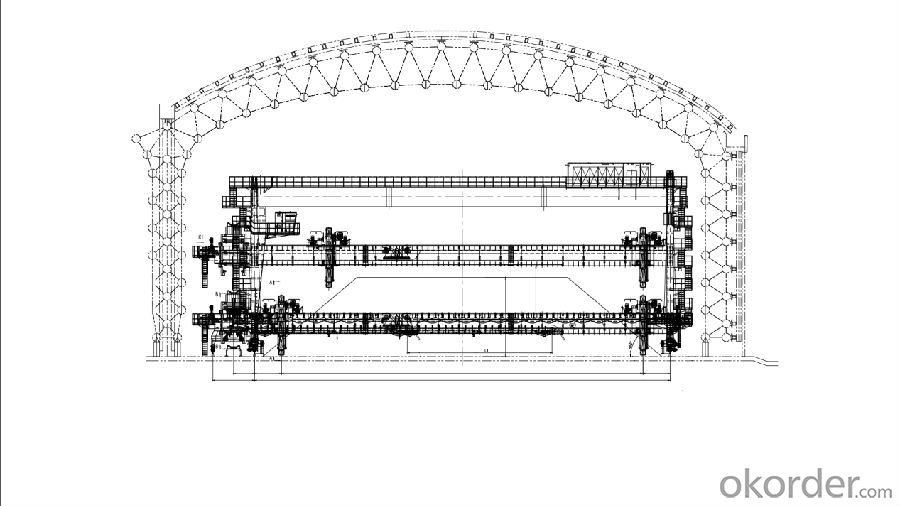

Overall Drawing

Technical Parameters

Model | Unit | MDQ | MDQ | MDQ | MDQ | MDQ | MDQ | |

Production Capacity | Stacking | t/h | 1000 | 1000 | 1500 | 2500 | 2000 | 2500 |

Reclaiming | t/h | 600 | 1000 | 800 | 1500 | 1800 | 2500 | |

Stacking Height | Upper Track | m | 8~12 | |||||

Lower Track | m | 0.5~2.5 | ||||||

Material Characteristics | Applicable Materials | Coal, coke, limestone, bauxite, iron ore, pellets, clay and other bulk materials | ||||||

Density | t/m³ | 0.5~2.5 | ||||||

Granularity | mm | 0~300 | ||||||

Bucket Wheel Diameter | m | 5~8 | ||||||

Conveyor | Belt Width | mm | 650~1800 | |||||

Belt Speed | m/s | 1.25~3.15 | ||||||

Travelling Speed | m/min | 5~30 VVVF (Variable Velocity Variable Frequency) | ||||||

Span | m | 50 | 40 | 60 | 45 | 50 | 60 | |

Max. Wheel Pressure | KN | 250/300 | ||||||

Steel Track | P50/Q80 | |||||||

Power Supply Mode | Cable Drum/Safety Trolley Line | |||||||

Communication Mode | Cable Drum/Safety Trolley Line /Wireless | |||||||

Control Mode | PLC Programme Control/Manual/Auto | |||||||

Constitution

The Gantry Bucket Wheel Stacker Reclaimer consists of tail car, cart travelling mechanism, towing system, anchoring and clamping device, movable beam lifting mechanism, balancing weight mechanism, roller mechanism, belt conveyor system of the equipment, coal hopper, driver room, electrical room, single beam crane, towing mechanism, ladder platform, safety device.

Feature

The Gantry Bucket Wheel Stacker Reclaimer has the characteristics of small footprint, large reserves, new structure, high automation degree, high environmental protection and so on. It can save a lot of civil engineering investment for the users, and the operation is simpler than other mechanical equipment. When the machine is unloaded in the process of taking materials, because of the small impact force, if the proper wear resistant material is added, the wear problem of the annual ring can be effectively reduced, thus prolonging its service life. In the process of transporting materials, the belt conveyor is usually used in the machine, and its resistance is small,rolling bearings are generally used in rotary parts, which can reduce the energy consumption of bucket wheel machines.

FAQ

How to determine the span and lifting height of the machine?

- Fully consider the layout of the material yard, such as the amount of storage and the length of the stacking of the material field under the conventional state, and reserve size on both sides of the material’s pile (such as traffic engineering vehicles and other equipment), then determine the size of the cross section of the pile, and then the optimal span and lifting height can be arranged.

How to determine the tail car type, such as single tail car, double tail car?

- Considering the overall process of material delivery, such as through, turn back, shunt conditions, and then determine the most economical layout form according to user needs.

Is there any obstacle to land transportation of this large equipment?

- Considering the different form of equipment delivery, under the condition of land transportation, the equipment design stage is based on the route transportation restrictions, according to the disintegration scheme processing to ensure the smoothness of land transportation.

Is the equipment which leave the factory equipped with random spare parts or vulnerable parts?

- According to the characteristics of the equipment for the use of high frequency, easy to wear parts with random spare parts, also provide spare parts list for the owners to choose, the spare parts should be signed with the owner what has a greater impact on cost.

How long is the equipment maintenance intervals?

- Different parts of the equipment maintenance intervals and methods are different, and refer to the equipment maintenance instructions.

Send your message to us

Gantry Bucket Wheel Stacker Reclaimer,Stacker and Reclaimer, Bulk Transportation Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches