Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1. High density 130kg/m3--950kg/m3

2. High working temp. 1150C.

3.100% no asbestos .

4.Low thermal conductivity <=0.040w/m.k

2,Main Features of the (Calcium Silicate Boards)

1:Good durability, and can withstand high-temperature limit of the continuous thermal load

2:We obtained CE, KR and ISO9001

3:The highest heat resistance temperature is up to 1150 degree centigrade

4:The maximum flexural strength is up to 0.7MPa,all Technical Parameters are the best in China, it is better than other calcium silicate board in the market.

5 Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

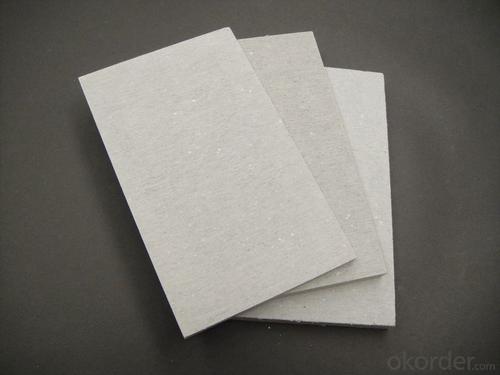

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Size & Loading Quantity of Calcium Silicate Board:

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS /

| Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS /

| Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS /

| Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS /

| Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS /

| Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

5,FAQ of (Calcium Silicate Boards)

Package

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing

Our Services:

We have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good! If you need samples we can proviod first then start production as your requirement!

- Q: What is the silicate? What is the price of calcium silicate and the market is much worse?

- Ette's product line is very long, from the general partition board to the high-end curtain wall are, their ingredients and production process is certainly different. Curtain wall panels can be used for more than 50 years. But it is also a fiber cement board. This kind of plate domestic price of several hundred dollars a square.

- Q: Calcium silicate board The so-called asbestos board is really no asbestos?

- The Etter board, which is part of the Belgian Etai Group, is a 100% non-asbestos manufacturer, which uses New Zealand imported shrub plant fibers. Is not enough to allow guests to visit the factory to watch the feeding shop when the feeding situation of the manufacturers, and the production of asbestos manufacturers can not take you to see the feeding situation.

- Q: Calcium silicate board 6MM how much money one

- Calcium silicate board regardless of the thickness of the millimeter, the price of each of their manufacturers are different, according to the price of raw materials, there are different ranges of rise or fall.

- Q: What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- Calcium silicate specifications are conventional specifications, that is, 1220x2440, or the use of conventional specifications more money, you want to be more expensive

- Q: Indoor compartment with calcium silicate board or gypsum board is good?

- In fact, home improvement, or calcium silicate board is good, although the price high. However, the characteristics of calcium silicate board determines the calcium silicate board refractory waterproof, long service life

- Q: Does the apartment use silicon calcium board to make the wall right?

- Calcium silicate board shortcomings: 1, the installation of calcium silicate board, the compartment would like to change, the replacement is not easy. 2, the installation of metal keel need to use, more cumbersome works, the price is more expensive.

- Q: External wall of calcium silicate board made of external wall paint

- In the putty powder surface polished and then brush the outer wall primer again, to be dry after. Brush the outer wall paint twice. carry out.

- Q: Calcium silicate board can be ground?

- Yes, you can ceiling, floor, etc. are possible, calcium silicate board light, waterproof, sound absorption is very easy to use

- Q: Calcium silicate sound - absorbing panels with what inspection lot

- Silicon calcium board is a compact board, basically airtight. Relative to the sound-absorbing panels heavier and harder. Is a sealed plate. Mainly from the sound effects. That is to stop the sound on both sides of the space in the spread of space.

- Q: Calcium silicate board can do the shape of the ceiling? If the figure can not, figure in the shape of what is generally used to do?

- Calcium silicate board is generally used to cut off rarely used to ceiling, you should be gypsum

Send your message to us

Calcium Silicate Boards Non-asbestos JN Standard Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords