Calcined Petroleum Coke Used as Carbon Additives

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Application: carben additives

Dimensions: fix carben morethan98%,sulphur less5%

Chemical Composition: nature graphite powder

attribute: briquette grade

shape: <SPAN style="BORDER-BOTTOM: 0px; BORDER-LEFT: 0px; PADDING-BOTTOM: 0px; MARGIN: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 0px; FONT-FAMILY: inherit; WORD-WRAP: break-word; VERTICAL-ALIGN: baseline; BORDER-TOP: 0px; BORDER-RIGHT: 0px; PADDING-TOP: 0px" class=attr-value title=block/powder>block/powder

classify: carbon additives/petroleum coke

Packaging & Delivery

| Packaging Details: | 50kg/bag,25kg/bag or as customer requirement |

|---|---|

| Delivery Detail: | 20DAYS after payment |

Specifications

Calcined Petroleum Coke Used as Carbon Additives

Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds.

Calcined Petroleum Coke

F.C.: 98.5%MIN

ASH: 0.8% MAX

V.M.: 0.7%MAX

S:0.5%MAX

Moisture: 0.5%MAX

Structure

Calcined Petroleum Coke Used as Carbon Additives

Shape: granule

- Dimensions: 0-1mm, 1-5mm, 1-6mm, 2-8mm, etc

- Product Type: Carbon Additive

- C Content (%): 98-99.5% MIN

- Working Temperature: -

- S Content (%): 0.5%-0.7%MAX

- Ash Content (%): 0.7%MAX

- Volatile:0.8%MAX

- Moisture: 0.5% MAX

- ADVANTAGE: low ash & sulfur

- COLOR: Black

Feature

Calcined Petroleum Coke Used as Carbon Additives

Physics and chemistry performance:

Unit | Index | |||||

No.1 | No.2 | No.3 |

| |||

Density | g/cm3 | 2.04 | 2.00 | 2.00 | ||

sulphur content | %≤ | 0.5 | 1.0 | 2.5 | ||

volatility | %≤ | 0.5 | 0.5 | 0.5 | ||

ash content | %≤ | 0.5 | 0.5 | 0.5 | ||

moisture | %≤ | 0.3 | 0.5 | 0.5 | ||

charcoal | %≤ | 98.5 | 98.0 | 98.0 | ||

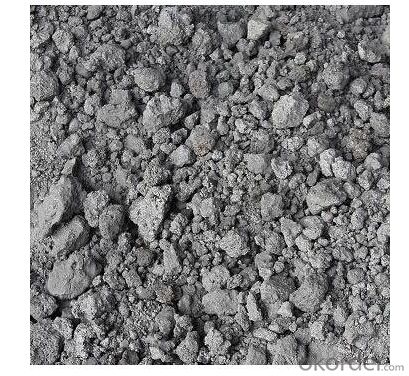

Image

Calcined Petroleum Coke Used as Carbon Additives

FAQ:

Calcined Petroleum Coke Used as Carbon Additives

How to classify calcined petroleum coke?

1) According to difference of sulfur content, can be divided into high sulfur coke (sulfur content more than 4%), sulphur in coke sulfur content (2% 4%) and low sulfur coke (sulfur content below 2%).

2) Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds:

3) Needle coke, has obvious needle-like structure and fiber texture, mainly used for steel-making in high power and ultra-high power graphite electrode. As a result of needle coke in sulfur content, ash content, volatile matter and true density and so on have strict quality requirements, so the production process of needle coke and raw materials have special requirements.

4) The sponge coke, high chemical reactivity, low content of impurities, mainly used in the aluminum industry and carbon industry.

5) Focal or spherical coke: the projectile shape is round, diameter 0.6-30 mm, usually from the production of high sulphur, high asphaltic residual oil, can only be used as industrial fuel power generation, cement etc.

6) Coke breeze: fluidized coking process, the fine particles (0.1- 0.4 mm) in diameter, high volatile, high expansion coefficient, cannot be directly used for electrode preparation and carbon industry.

Advantage:

Calcined Petroleum Coke Used as Carbon Additives

1. High quality and competitive price.

2. Timely delivery.

3. If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How are carbon fibers produced?

- Carbon fibers are produced through a multi-step process known as carbonization. The process starts with a raw material called precursor, which is usually a polymer-based material such as polyacrylonitrile (PAN), rayon, or pitch. The first step involves spinning the precursor material into long, thin fibers. This can be done through various methods such as melt spinning, dry spinning, or wet spinning, depending on the type of precursor used. Once the fibers are formed, they undergo a stabilization process. This involves heating the fibers in the presence of oxygen at a relatively low temperature, usually around 200-300 degrees Celsius. Stabilization helps to remove any volatile components from the fibers and align the molecular structure in a way that enhances its heat resistance and strength. After stabilization, the fibers are subjected to a high-temperature treatment called carbonization. This process takes place in a furnace with little or no oxygen, typically at temperatures above 1000 degrees Celsius. During carbonization, the fibers are heated to a point where most of the non-carbon atoms are expelled, leaving behind a highly pure carbon structure. The final step in the production of carbon fibers is surface treatment. This involves applying a coating or treatment to the fibers to improve their bonding properties and adhesion with other materials. The surface treatment can be done using various methods such as sizing, coating, or plasma treatment. Overall, the production of carbon fibers involves a combination of spinning, stabilization, carbonization, and surface treatment processes to create fibers with exceptional strength, stiffness, and low weight. These properties make carbon fibers highly sought after in various industries, including aerospace, automotive, sports, and construction.

- Q: How does carbon impact the availability of sustainable agriculture practices?

- Carbon impacts the availability of sustainable agriculture practices by affecting climate change and soil health. Excessive release of carbon dioxide into the atmosphere contributes to global warming, altering weather patterns and making it harder for farmers to maintain consistent crop yields. Additionally, excessive carbon in the atmosphere leads to increased acidity in the oceans, affecting marine ecosystems and seafood availability. On the other hand, carbon sequestration through practices like agroforestry and regenerative agriculture helps mitigate climate change, improves soil fertility, and promotes sustainable farming methods. By reducing carbon emissions and adopting carbon sequestration techniques, sustainable agriculture practices can be more readily available and effective in ensuring long-term food security.

- Q: How is carbon used in the production of rubber?

- Due to its unique properties and ability to enhance the overall quality and performance of rubber products, carbon finds widespread use in rubber production. An essential component in rubber manufacturing, carbon black is formed when hydrocarbons are incompletely burned. To enhance the strength, durability, and resistance to wear and tear of rubber, carbon black is added to rubber formulations. Acting as a reinforcing agent, it increases tensile strength and abrasion resistance by interlocking with the rubber polymer chains and fortifying the material's overall structure, making it more resilient. Moreover, carbon black improves the electrical conductivity of rubber, making it valuable in applications that require conductivity. It also enhances the rubber's resistance to degradation from exposure to sunlight by boosting its UV resistance. Furthermore, carbon black can enhance the color and appearance of rubber products, imparting a deep black hue. Furthermore, carbon black can serve as a filler in rubber compounds, reducing production costs while maintaining or even improving the rubber's mechanical properties. By substituting part of the more expensive rubber polymer with carbon black, manufacturers can achieve cost savings without compromising the desired performance characteristics of the rubber. In conclusion, carbon plays a vital role in rubber production by enhancing its strength, durability, conductivity, UV resistance, and appearance. Rubber products would lack the necessary properties for their intended applications without carbon.

- Q: What is carbon black ink?

- The main component of carbon black ink is carbon black pigment. Carbon black, a fine powder produced from carbon through incomplete combustion of hydrocarbons, is commonly used as a pigment in the ink industry due to its intense black color, excellent opacity, and resistance to UV rays. When it comes to applications, carbon black ink is widely utilized in printing, writing, and drawing. It can be found in ballpoint pens, fountain pens, markers, and printer inks. The ink's high concentration of carbon black pigment ensures a deep and solid black color on different surfaces, including paper. One of the advantages of carbon black ink is its durability. It has exceptional lightfastness, meaning it does not fade or change color when exposed to light over time. This is particularly crucial for applications that require long-lasting or archival-quality ink, such as art or document preservation. Moreover, carbon black ink exhibits good water resistance and adhesion properties, making it suitable for use on various materials like paper, cardboard, and plastics. Its high viscosity ensures consistent and smooth ink flow, allowing for precise and consistent writing or printing. In conclusion, carbon black ink is a versatile and reliable ink that offers an intense black color, excellent durability, and good adhesion properties. Its widespread use in various writing and printing applications showcases its quality and dependability.

- Q: How are carbon nanotubes used in various applications?

- Carbon nanotubes possess remarkable versatility and have discovered countless applications across diverse fields. In the realm of electronics, they serve as an alternative to conventional silicon-based materials, thereby facilitating the creation of smaller, faster, and more efficient devices. They function as the fundamental components for transistors, interconnects, and memory devices. Within the energy sector, researchers are exploring the potential of carbon nanotubes to enhance battery and supercapacitor performance. Their exceptional electrical conductivity and expansive surface area render them ideal for augmenting energy storage and expediting charge and discharge rates. Moreover, carbon nanotubes find utility in the realm of materials science. By incorporating them into composites, it is possible to bolster their strength, rigidity, and electrical conductivity. These composites prove valuable in the aerospace, automotive, and construction industries, where lightweight and durable materials are in high demand. Furthermore, carbon nanotubes are under investigation for their medical applications. Thanks to their distinct properties, they can be utilized in drug delivery systems, sensors, and imaging technologies. They possess the ability to selectively target cancer cells, thereby enabling more efficient and precise treatment alternatives. To summarize, carbon nanotubes offer an extensive array of applications, ranging from electronics and energy storage to materials science and medicine. Their exceptional properties make them highly coveted for enhancing performance and driving advancements across various industries.

- Q: How does carbon cycle through the environment?

- Carbon moves between the atmosphere, land, oceans, and living organisms in a continuous cycle known as the carbon cycle. This cycle is essential for maintaining a stable climate and supporting life on Earth. To begin, carbon dioxide (CO2) in the atmosphere is absorbed by plants during photosynthesis. Plants convert CO2 into organic carbon compounds, such as sugars and carbohydrates, which they use for growth and energy. Animals then consume these plants or other animals, passing the carbon along the food chain. When plants and animals die or excrete waste, their organic matter decomposes, releasing carbon back into the environment. Microorganisms, like bacteria and fungi, break down the organic matter and release carbon dioxide as a byproduct. Some carbon can be stored in the soil for long periods, depending on factors like temperature and moisture. This stored carbon in the soil may be released back into the atmosphere through processes like microbial respiration or erosion. Fossil fuel burning, including coal, oil, and natural gas, is another way carbon returns to the atmosphere. When these fuels are burned for energy, they release carbon dioxide, contributing to the greenhouse effect and climate change. The oceans also play a vital role in the carbon cycle. They absorb a significant amount of carbon dioxide from the atmosphere through carbon sequestration. Marine plants, like phytoplankton, also photosynthesize and store carbon in their tissues. When these organisms die, they sink to the ocean floor, where the carbon can be stored as sediment or dissolved in the water for long periods. Oceanic circulation and biological processes redistribute carbon throughout the oceans, with surface water exchanging carbon with the atmosphere. Furthermore, the oceans act as a carbon sink, storing large amounts of carbon dioxide and helping to regulate its levels in the atmosphere. In conclusion, the carbon cycle is a complex and interconnected process involving various natural and human activities. Understanding and managing this cycle is crucial for mitigating climate change and maintaining a healthy environment.

- Q: What are the benefits of carbon-neutral technologies?

- Carbon-neutral technologies have numerous benefits that make them a vital solution in combating climate change and creating a sustainable future. Firstly, these technologies help to reduce greenhouse gas emissions, particularly carbon dioxide, which is the primary contributor to global warming. By transitioning to carbon-neutral technologies, we can significantly decrease our carbon footprint and mitigate the harmful effects of climate change. Secondly, carbon-neutral technologies promote energy efficiency and resource conservation. Many of these technologies, such as renewable energy sources like solar and wind power, harness natural resources that are infinite and readily available. This reduces our reliance on finite fossil fuels, which not only helps to protect the environment but also reduces the volatility of energy prices. Furthermore, embracing carbon-neutral technologies can lead to improved air quality and public health. Traditional energy sources like coal and oil contribute to air pollution and have detrimental health effects on humans, such as respiratory issues and cardiovascular diseases. By transitioning to cleaner technologies, we can reduce air pollution and improve the quality of life for individuals and communities. In addition, carbon-neutral technologies can stimulate economic growth and create new job opportunities. The development, installation, and maintenance of renewable energy infrastructure require skilled workers, leading to job creation and economic development. This transition can also reduce dependency on imported energy sources, leading to greater energy independence and national security. Lastly, by adopting carbon-neutral technologies, we can demonstrate global leadership and contribute to international efforts to combat climate change. Countries that embrace these technologies become role models for others and encourage global cooperation in reducing greenhouse gas emissions. In conclusion, the benefits of carbon-neutral technologies are vast and multidimensional. They not only help mitigate climate change and reduce greenhouse gas emissions but also promote energy efficiency, improve air quality, stimulate economic growth, and contribute to global efforts in creating a sustainable future.

- Q: What is the relationship between carbon emissions and air pollution?

- Carbon emissions contribute to air pollution. When carbon-based fuels such as coal, oil, and natural gas are burned, they release carbon dioxide (CO2) into the atmosphere. This CO2, along with other pollutants like nitrogen oxides and sulfur dioxide, can react with sunlight and other chemicals in the air to form smog and particulate matter. These pollutants can have detrimental effects on air quality, human health, and the environment, making the relationship between carbon emissions and air pollution significant.

- Q: How does carbon impact the stability of tundra ecosystems?

- Carbon impacts the stability of tundra ecosystems by altering the delicate balance of temperature and nutrient availability. As carbon emissions increase, the greenhouse effect intensifies, leading to rising temperatures. This can cause permafrost to thaw, resulting in increased soil erosion, changes in hydrology, and disturbance to vegetation. Additionally, the release of carbon stored in the soil can further amplify global warming. Overall, the impact of carbon on tundra ecosystems can disrupt the fragile ecological relationships and threaten the stability of these unique and vulnerable environments.

- Q: The difference between graphite and carbon

- There are three kinds of carbon allotropes, namely diamond, graphite and amorphous carbon.Graphite is a crystalline mineral of carbonaceous elements, and its crystalline framework is hexagonal layered structure

Send your message to us

Calcined Petroleum Coke Used as Carbon Additives

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords