Calcined Petroleum Coke as Injection Coke called Carbon Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.8

- Supply Capability:

- 1004 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

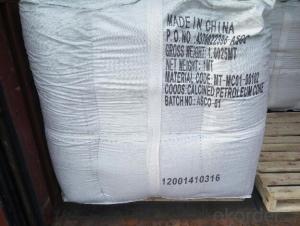

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: How does carbon impact the availability of natural resources?

- Carbon impacts the availability of natural resources by contributing to climate change. Excessive carbon emissions, primarily from burning fossil fuels, lead to global warming, which in turn affects the availability and distribution of resources such as water, food, and energy. Additionally, carbon pollution can cause ocean acidification, harming marine ecosystems and reducing fish populations. Therefore, controlling carbon emissions is crucial to ensure the sustainable availability of natural resources.

- Q: What are the advantages of carbon-based nanoelectronics?

- Carbon-based nanoelectronics offer several advantages over traditional silicon-based electronics. Firstly, carbon-based materials, such as nanotubes and graphene, have exceptional electrical properties. They can carry high electron mobility, meaning they can transport charges at a much higher speed than silicon. This allows for faster and more efficient electronic devices. Secondly, carbon-based nanoelectronics have excellent thermal properties. They can efficiently dissipate heat, reducing the risk of overheating in electronic devices. This is particularly beneficial for high-power applications, where heat management is crucial. Additionally, carbon-based nanoelectronics are extremely thin and flexible. Nanotubes and graphene can be easily manipulated to create ultra-thin and flexible electronic components. This enables the development of wearable electronics, flexible displays, and other innovative devices that were previously not possible with silicon-based technology. Carbon-based materials also have a higher mechanical strength compared to silicon. They are more resistant to bending or breaking, making them more durable and long-lasting. Furthermore, carbon-based nanoelectronics have the potential for scalability. They can be fabricated using various methods, including chemical vapor deposition and solution-based processes, which offer the possibility of large-scale production at lower costs. Lastly, carbon-based nanoelectronics are environmentally friendly. Carbon is an abundant element and does not pose the same environmental concerns as silicon, which requires energy-intensive processes for extraction and purification. Overall, carbon-based nanoelectronics offer improved electrical and thermal properties, flexibility, scalability, durability, and environmental sustainability. These advantages make them highly promising for the development of next-generation electronic devices.

- Q: What is the greenhouse effect?

- The greenhouse effect refers to the process by which certain gases in the Earth's atmosphere trap heat from the sun and prevent it from escaping back into space. This natural phenomenon is crucial for maintaining the planet's temperature within a range suitable for life. However, human activities, such as burning fossil fuels and deforestation, have intensified the greenhouse effect, leading to global warming and climate change.

- Q: What are the effects of carbon emissions on the stability of estuaries?

- Carbon emissions have significant effects on the stability of estuaries. Estuaries are highly productive and diverse ecosystems that serve as a crucial habitat for numerous species, including fish, birds, and other wildlife. However, excessive carbon emissions, primarily in the form of carbon dioxide (CO2), contribute to climate change and ocean acidification, which in turn have detrimental effects on estuaries. One of the most prominent effects of carbon emissions on estuaries is the rise in sea levels. As global temperatures increase due to carbon emissions, glaciers and ice caps melt, leading to a rise in sea levels. Estuaries, being low-lying areas where rivers meet the sea, are particularly vulnerable to this sea-level rise. Higher water levels can result in increased flooding, erosion, and saltwater intrusion into freshwater systems within estuaries, impacting the overall stability of these ecosystems. Moreover, the increased concentration of CO2 in the atmosphere leads to ocean acidification. When CO2 dissolves in seawater, it reacts with water to form carbonic acid, which lowers the pH of the water. This acidification has detrimental effects on the marine life within estuaries, including shellfish, oysters, and other organisms with calcium carbonate shells. The acidity makes it more difficult for these organisms to build and maintain their shells, leading to reduced populations and biodiversity within estuaries. Additionally, climate change caused by carbon emissions alters the temperature and precipitation patterns in estuaries, affecting the balance of salinity and freshwater influx. Estuaries rely on a delicate balance of saltwater and freshwater to support their unique ecosystems. Changes in temperature and precipitation can disrupt this balance, leading to significant shifts in species composition and distribution. Some species may struggle to adapt to these changes, while invasive species may thrive, further altering the stability and integrity of estuarine ecosystems. Overall, the effects of carbon emissions on the stability of estuaries are profound and multifaceted. Rising sea levels, ocean acidification, and climate-induced changes in salinity and freshwater availability all contribute to the degradation of estuaries and the loss of biodiversity. It is crucial to reduce carbon emissions and mitigate climate change to protect and preserve these vital ecosystems for future generations.

- Q: What are the properties of activated carbon?

- Activated carbon, also known as activated charcoal, possesses several unique properties that make it highly versatile and useful in various applications. 1. Adsorption: One of the most significant properties of activated carbon is its high adsorptive capacity. It has a vast internal surface area due to its porous structure, which allows it to effectively adsorb molecules, ions, and impurities from gases, liquids, and solids. This adsorption capability makes it ideal for purification purposes, such as water and air filtration, as well as in the removal of toxins and pollutants from industrial processes. 2. Porosity: Activated carbon has a highly porous structure with a network of interconnected pores. This porosity provides a large surface area, enabling it to trap a significant amount of contaminants. The pores can be classified into three types: micropores (less than 2 nm), mesopores (2-50 nm), and macropores (greater than 50 nm), each contributing to its adsorption capacity. 3. Chemical Stability: Activated carbon exhibits excellent chemical stability, making it resistant to degradation and breakdown when exposed to various chemicals or environments. This property allows it to maintain its adsorption capacity over a long period and under harsh conditions, ensuring its efficiency and longevity in different applications. 4. Selectivity: Activated carbon can be tailored to exhibit selectivity towards specific substances by modifying its surface properties. Through various activation processes, such as physical or chemical treatments, the surface chemistry of activated carbon can be altered to enhance its affinity for certain molecules or contaminants, while reducing its affinity for others. This selectivity makes it an effective material for specific applications, such as removing specific pollutants or capturing desired compounds. 5. Regenerability: Another advantageous property of activated carbon is its regenerability. After reaching its adsorption capacity, it can be regenerated by heating or washing with appropriate solvents, allowing it to be reused multiple times before replacement. This regenerability not only reduces the operational costs but also contributes to its sustainability and eco-friendliness. 6. Low Density: Activated carbon has a relatively low density, making it lightweight and easy to handle. This property enables its use in various systems and devices without adding excessive weight or bulk. 7. Thermal Stability: Activated carbon possesses high thermal stability, allowing it to withstand high temperatures without significant degradation. This property makes it suitable for applications involving high-temperature processes, such as gas purification or catalytic reactions. Overall, the properties of activated carbon, including its adsorption capacity, porosity, chemical stability, selectivity, regenerability, low density, and thermal stability, make it a versatile material widely used in water and air purification, gas separation, chemical processing, pharmaceuticals, and many other industries.

- Q: What are the applications of carbon nanomaterials in medicine?

- Carbon nanomaterials have emerged as promising tools in the field of medicine due to their unique properties and potential applications. One of the key applications of carbon nanomaterials in medicine is in drug delivery systems. These nanomaterials can be functionalized with drugs, making them capable of targeted delivery to specific cells or tissues. The large surface area of carbon nanomaterials allows for more efficient drug loading, enabling improved therapeutic efficacy and reduced side effects. Carbon nanomaterials also show great potential in the field of tissue engineering. They can be used as scaffolds to support the growth and regeneration of damaged tissues. Carbon nanomaterials possess excellent mechanical strength and biocompatibility, making them suitable for applications such as bone and cartilage repair. Additionally, their electrical and thermal conductivity properties make them ideal for creating bioelectrodes and biosensors, which can be used for various diagnostic and monitoring purposes. Furthermore, carbon nanomaterials have been explored for their antimicrobial properties. They have shown the ability to inhibit the growth of bacteria and fungi, making them potential candidates for developing new antimicrobial agents. This could be particularly useful in preventing and treating infections in medical devices and implants. Another application of carbon nanomaterials in medicine is in imaging and diagnostics. These nanomaterials can be used as contrast agents in various imaging techniques, such as magnetic resonance imaging (MRI) and fluorescence imaging. Their unique optical and magnetic properties allow for enhanced imaging and improved detection of diseases, such as cancer. Carbon nanomaterials also hold promise in the field of cancer therapy. They can be used in photothermal therapy, where the nanomaterials are exposed to light, converting it into heat and selectively killing cancer cells. Additionally, carbon nanomaterials can be used in photodynamic therapy, where they generate reactive oxygen species upon light activation, leading to cancer cell destruction. In summary, carbon nanomaterials have a wide range of applications in medicine. They offer the potential for targeted drug delivery, tissue engineering, antimicrobial agents, diagnostic imaging, and cancer therapy. Continued research and development in this field hold great promise for revolutionizing medical treatments and improving patient outcomes.

- Q: Carbon content of fly ash and fly ash roasted vector what is the relationship?

- The loss of coal ash is mainly caused by the incomplete combustion of coal, the remaining carbon is introduced, and the carbon content is high, then the amount of burning is high. From the color, it can be clearly seen that the black fly ash has high carbon content and high ignition loss. Based on the molecular weights of C and CO2, a preliminary estimate is made.

- Q: What role does carbon play in photosynthesis?

- Carbon plays a crucial role in photosynthesis as it is the primary building block for organic molecules. During photosynthesis, carbon dioxide is taken in by plants and converted into glucose, a simple sugar, using energy from sunlight. This glucose is then used to synthesize more complex carbohydrates, such as starch, cellulose, and other organic molecules, which are essential for plant growth and development.

- Q: What is carbon pricing?

- Carbon pricing refers to a policy mechanism that aims to reduce greenhouse gas emissions by assigning a monetary value to carbon dioxide and other greenhouse gas emissions. It essentially puts a price on the carbon content of fossil fuels and other activities that release greenhouse gases into the atmosphere. The main objective of carbon pricing is to incentivize businesses, industries, and individuals to reduce their carbon emissions by making it more economically viable to adopt cleaner and more sustainable practices. There are two primary methods of carbon pricing: carbon taxes and cap-and-trade systems. A carbon tax sets a fixed price per ton of carbon emissions, which businesses and industries must pay based on their emissions levels. This tax creates a financial incentive for companies to reduce their emissions to avoid higher costs. On the other hand, cap-and-trade systems set a limit, or cap, on the total amount of emissions allowed in a given period. Companies are then allocated a certain number of emissions permits, which they can buy, sell, or trade with other companies. This system creates a market for emissions, where companies that can reduce their emissions more easily can sell their surplus permits to those struggling to meet their targets. The revenue generated from carbon pricing can be used in various ways. It can be reinvested into renewable energy projects, energy efficiency initiatives, or research and development of clean technologies. It can also be used to support vulnerable communities affected by the transition to a low-carbon economy or to offset the economic impacts on industries that may face challenges in reducing their emissions. Carbon pricing is considered an effective tool for tackling climate change, as it provides a clear economic signal to businesses and individuals to reduce their carbon footprint. By placing a price on carbon, it internalizes the costs associated with climate change and encourages the adoption of cleaner alternatives. It also helps to level the playing field between polluting industries and those investing in low-carbon technologies, creating an incentive for innovation and the development of sustainable practices.

- Q: What is the boiling point of carbon?

- The boiling point of carbon, a nonmetallic element, depends on its allotrope. Carbon has multiple allotropes, including graphite and diamond, each with different physical properties. Graphite, which consists of layers of carbon atoms arranged in a hexagonal lattice, does not have a boiling point since it sublimes directly from a solid to a gas. On the other hand, diamond, which is composed of carbon atoms arranged in a three-dimensional lattice, also does not have a boiling point as it undergoes direct sublimation. Therefore, carbon does not have a boiling point in its pure elemental form.

Send your message to us

Calcined Petroleum Coke as Injection Coke called Carbon Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.8

- Supply Capability:

- 1004 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords