Calcined Anthracite Coal FC 90-95% for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Calcined Coal FC 90-95% for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Calcined Coal FC 90-95% for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Calcined Coal FC 90-95% for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

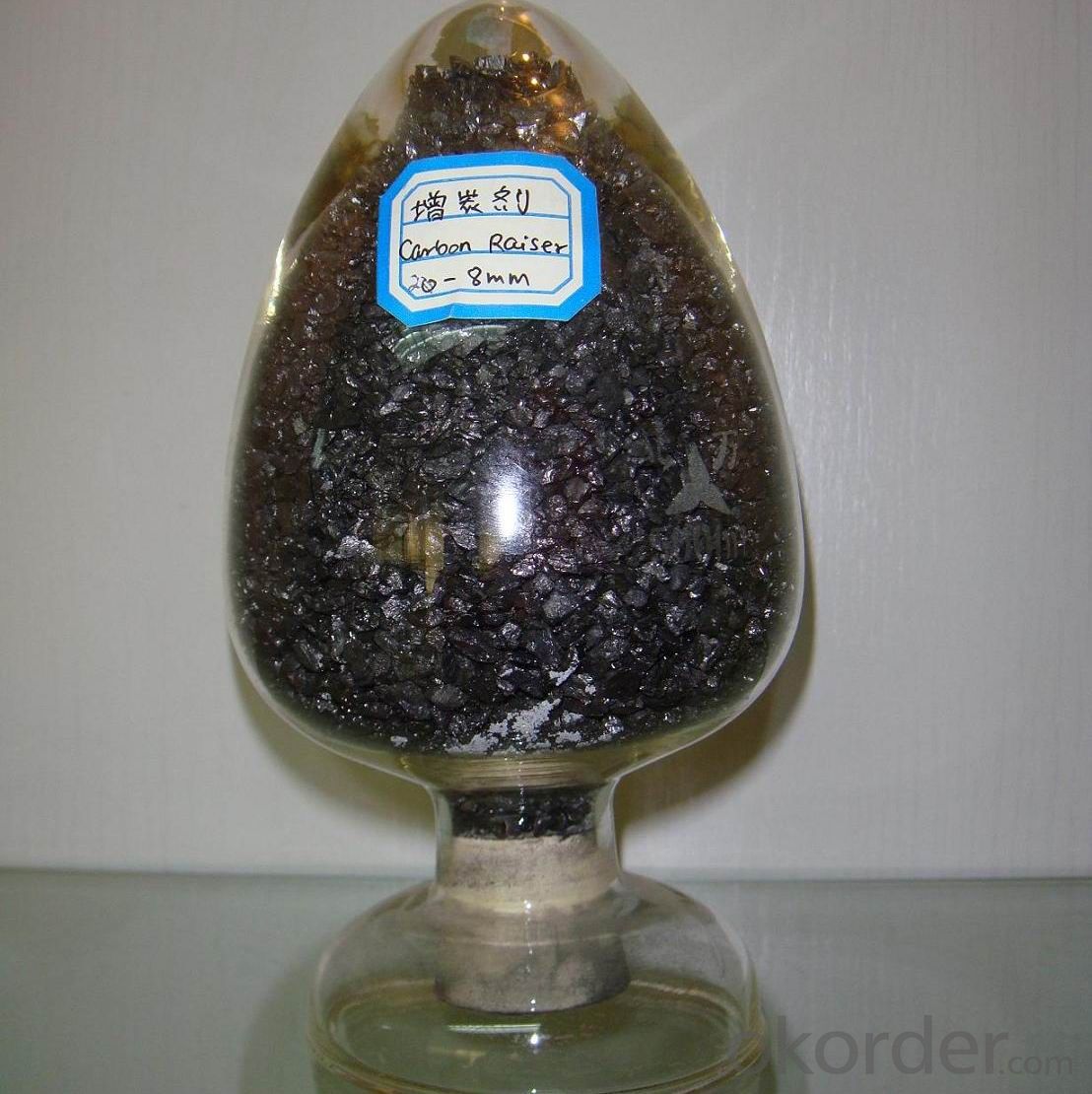

Image

Calcined Coal FC 90-95% for Steelmaking

FAQ:

Calcined Coal FC 90-95% for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Calcined Coal FC 90-95% for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How does carbon dioxide contribute to ocean acidification?

- Carbon dioxide contributes to ocean acidification through a process called carbonic acid formation. When carbon dioxide dissolves in seawater, it reacts with water molecules to form carbonic acid. This reaction increases the concentration of hydrogen ions in the water, leading to a decrease in pH, making the water more acidic. As carbon dioxide emissions from human activities, particularly the burning of fossil fuels, continue to increase, more and more carbon dioxide is being absorbed by the oceans. This excessive absorption is disrupting the natural equilibrium that exists between carbon dioxide in the atmosphere and in the ocean, resulting in a surplus of carbon dioxide in the seawater. The increased acidity of the seawater can have severe consequences for marine life. Many marine organisms such as corals, shellfish, and certain types of plankton depend on calcium carbonate to build their shells or skeletons. However, in more acidic water, the availability of carbonate ions, which are necessary for the formation of calcium carbonate, decreases. As a result, these organisms struggle to build and maintain their protective structures, making them more vulnerable to predation and other threats. Ocean acidification also affects the growth, development, and behavior of many other marine species. For instance, acidification can disrupt the reproductive cycles of fish and alter the behavior of some species, making them more prone to predation or negatively impacting their ability to find food or mates. Furthermore, ocean acidification can have cascading effects on entire marine ecosystems. Many species in the ocean are interconnected in complex food webs, and any disruption to one species can have far-reaching consequences on others. For example, if the population of a certain fish species declines due to the impacts of acidification, it can have a ripple effect on the entire food chain, affecting the abundance and distribution of other species. In summary, carbon dioxide contributes to ocean acidification by dissolving in seawater and forming carbonic acid, which increases the concentration of hydrogen ions and decreases the pH. This process can have detrimental effects on marine organisms, particularly those that rely on calcium carbonate for their shells or skeletons. It can also disrupt the growth, development, and behavior of various marine species and have cascading impacts on entire ecosystems.

- Q: How does carbon impact biodiversity?

- Carbon impacts biodiversity in several ways. Firstly, carbon dioxide is a greenhouse gas that contributes to climate change, leading to shifts in temperature and precipitation patterns. These changes can disrupt ecosystems and alter habitats, affecting the distribution and survival of various species. Additionally, excess carbon in the atmosphere can lead to ocean acidification, which negatively affects marine biodiversity by harming coral reefs and other organisms reliant on calcium carbonate structures. Finally, deforestation and land-use changes associated with carbon emissions result in habitat loss, further reducing biodiversity. Overall, carbon emissions have significant and detrimental impacts on the delicate balance of ecosystems and the diversity of life on Earth.

- Q: Speak in detail! I am ~ carbon Roast Lamb Leg lamb chops lamb barbecue ah ~ ~ how to do with practice video line! And how do you bake the oven?

- Step 2: prepare garlic paste, starch paste, mixed evenly, with the barbecue. The purpose is to make the lamb roast outside tender, and not paste, garlic flavor rich, delicious, very delicious, this is a unique secret recipe, dedication. Step 3: students after adding charcoal, grill, the best 30 cm distance between the grill with charcoal, around to gather, the formation of hot absolute direction, to avoid heat loss. Lamb must be able to rack up and down around the inversion freely, to evenly bake. Bake for 7 minutes until the lamb cooked, mashed garlic paste to wipe, scorched yellow Maoyou creaking, sprinkle with pepper and natural. Time to master almost on the line. Because mutton has the distinction between the old lamb and the lamb, it is difficult to grasp the baking time. If you use a home electric oven, you'll need to marinate the mutton first. Methods: fresh meat (lean half) dice, into the pot, cumin, pepper, fennel, two, ginger,

- Q: How does carbon dioxide affect ocean acidity?

- Ocean acidification, a process caused by the presence of carbon dioxide, is responsible for the increased acidity in the ocean. Human activities, such as the burning of fossil fuels, release carbon dioxide into the atmosphere, and a significant portion of it is absorbed by the oceans. This excess carbon dioxide reacts with seawater and forms carbonic acid, which then dissociates into hydrogen ions and bicarbonate ions. The rise in hydrogen ions reduces the ocean's pH level, resulting in increased acidity. The elevated acidity of the ocean negatively impacts marine life in several ways. Marine organisms, including corals, shellfish, and plankton, are unable to construct and maintain their calcium carbonate structures, such as shells and exoskeletons, due to this condition. This can lead to slower growth rates, weakened structures, and higher mortality rates among these organisms. The survival and reproduction of various species, including fish and other marine animals, are also affected by ocean acidification. The changes in water chemistry disrupt their physiological processes, making it difficult for them to navigate, find food, and evade predators. Moreover, the increased acidity can alter the behavior and development of certain species, potentially causing changes in ecosystems and a decline in biodiversity. Ocean acidification can also have a cascading effect on the entire marine food web. Phytoplankton and other primary producers, which are the foundation of the food chain, may suffer due to the changing ocean chemistry. Consequently, the organisms that rely on them for sustenance are also impacted. This disruption can have far-reaching consequences for the entire ecosystem, including commercially valuable fish species and the livelihoods of coastal communities that depend on them. In conclusion, the emissions of carbon dioxide contribute to ocean acidification, which has severe consequences for marine life and ecosystems. It is crucial to comprehend and address this issue in order to safeguard the health and sustainability of our oceans and the countless species that depend on them.

- Q: Why are biological molecules carbon based molecular aggregates?

- Because living things are living organisms, most of them consist of organic compounds, which are carbon compounds, and carbon chains are the main body

- Q: What is the most common isotope of carbon?

- Carbon-12, the most prevalent carbon isotope, derives its name from its atomic mass of 12 atomic mass units, determined by the composition of protons and neutrons in its nucleus. It dominates the natural abundance of carbon, comprising approximately 98.9% of all carbon atoms. In contrast, carbon-13 and carbon-14, the other two carbon isotopes, occur in lesser quantities and proportions. Being stable and resistant to radioactive decay, carbon-12 holds great significance as a vital element for sustaining life on our planet.

- Q: What is carbon neutral construction?

- Carbon neutral construction entails a sustainable approach to constructing and designing structures that aims to minimize or counterbalance the amount of carbon emissions generated during the construction process. The objective is to achieve equilibrium between the carbon emissions released into the atmosphere and those that are eliminated or offset through various measures. To accomplish carbon neutrality in construction, several strategies can be employed. Firstly, the implementation of energy-efficient design principles helps reduce the overall energy consumption of the building. This includes incorporating insulation, efficient HVAC systems, and energy-saving appliances and lighting. In addition, sustainable building materials are utilized, such as recycled materials or those with a minimal carbon footprint. This decreases the energy required for material production and transportation, thus minimizing carbon emissions. Moreover, renewable energy sources are integrated into the construction process. This may involve the installation of solar panels, wind turbines, or geothermal systems to generate clean energy for the building's operations. By reducing reliance on fossil fuels, carbon emissions associated with energy consumption are significantly decreased. Carbon offsetting is another crucial element of carbon neutral construction. This entails investing in projects or initiatives that reduce or eliminate greenhouse gas emissions elsewhere, thereby compensating for the emissions produced during construction. Examples of carbon offsetting activities include reforestation projects, investment in renewable energy initiatives, or support for methane capture programs. Ultimately, carbon neutral construction aims to minimize the environmental impact of building construction and operation by reducing carbon emissions throughout the entire lifespan of the building. By adopting energy-efficient design principles, utilizing sustainable materials, integrating renewable energy sources, and offsetting carbon emissions, carbon neutral construction contributes to the mitigation of climate change and the creation of a more sustainable future.

- Q: How can carbon be stored underground?

- Carbon can be stored underground through a process called carbon capture and storage (CCS). This involves capturing carbon dioxide emissions from industrial processes or power plants, compressing it into a liquid form, and injecting it into deep underground geological formations, such as depleted oil and gas reservoirs or saline aquifers. The carbon dioxide is then trapped underground, preventing it from entering the atmosphere and contributing to climate change.

- Q: How is carbon dioxide released into the atmosphere?

- Carbon dioxide is emitted into the atmosphere due to a range of natural and human activities. The burning of fossil fuels, like coal, oil, and natural gas, for energy generation is one of the main sources of carbon dioxide. Combustion of these fuels releases carbon dioxide as a byproduct, which occurs in power plants, factories, and vehicles that rely on fossil fuels for energy. Deforestation and changes in land use also contribute to the release of carbon dioxide into the atmosphere. Through photosynthesis, trees absorb carbon dioxide, and when they are cut down or burned, the stored carbon is released back into the atmosphere. This is especially significant in tropical rainforests, which store large amounts of carbon in their vegetation. Furthermore, natural processes like respiration and volcanic eruptions release carbon dioxide into the atmosphere. In respiration, living organisms, including humans and animals, take in oxygen and exhale carbon dioxide as a waste product. Volcanic eruptions release carbon dioxide that was stored in magma and rock formations. In general, the release of carbon dioxide into the atmosphere is a combination of natural and human activities. However, human activities, particularly the burning of fossil fuels and deforestation, have significantly raised the levels of carbon dioxide in the atmosphere, resulting in the greenhouse effect and climate change.

- Q: How is carbon used in water filtration systems?

- Carbon is used in water filtration systems as a filter medium or adsorbent. It effectively removes impurities, such as chlorine, volatile organic compounds (VOCs), and other contaminants, by adsorbing them onto its porous surface. This process helps improve the taste, odor, and overall quality of drinking water.

Send your message to us

Calcined Anthracite Coal FC 90-95% for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches