Calcined Anthracite Coal CA Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

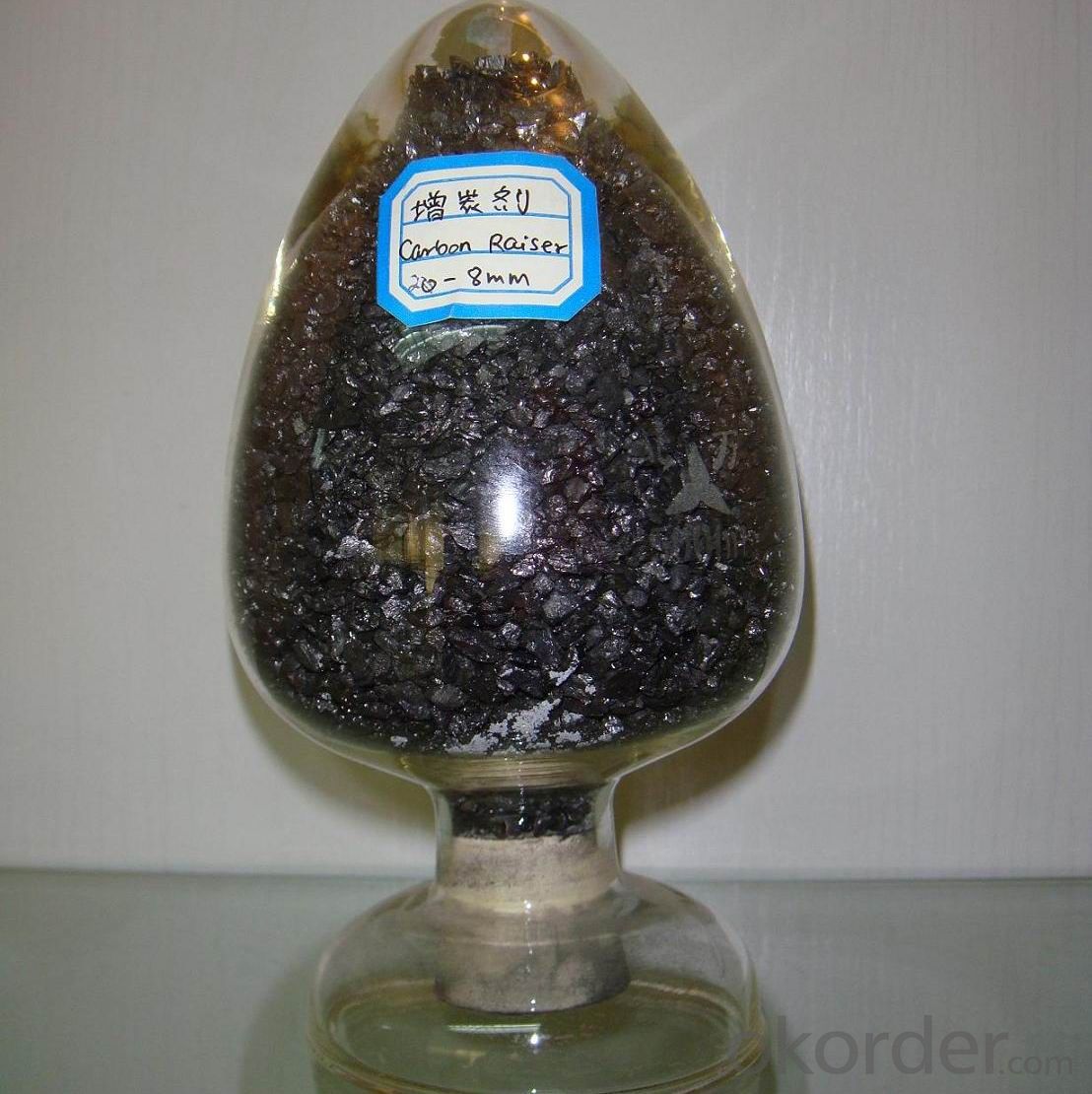

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Calcined Anthracite Coal CA Description

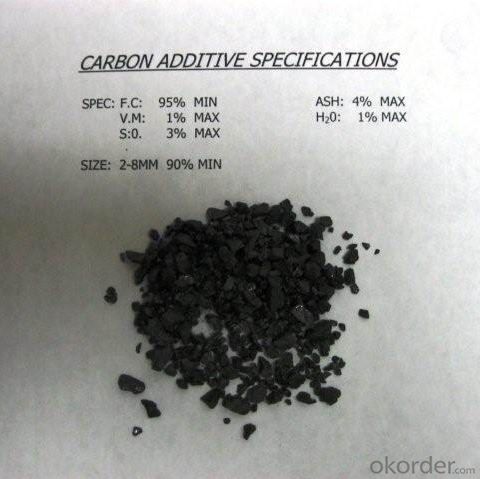

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Calcined Anthracite Coal CA Description

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Calcined Anthracite CA Description

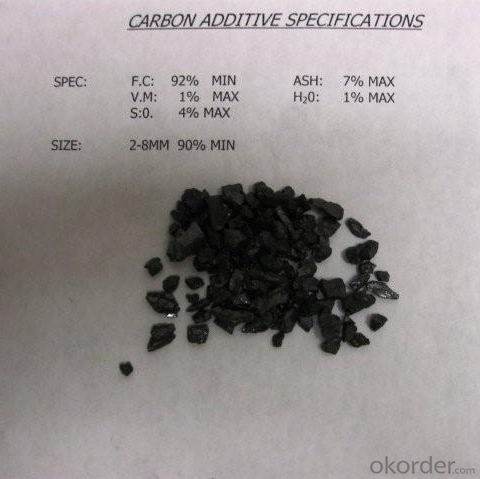

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Calcined Anthracite Coal CA Description

FAQ:

Calcined Anthracite Coal CA Description

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Calcined Anthracite Coal CA Description

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How is carbon used in the production of carbon nanomaterials?

- Carbon is essential in creating carbon nanomaterials due to its role as the foundation for their distinct structure and properties. Various techniques are employed to manufacture carbon nanomaterials, including carbon nanotubes and graphene, all of which rely on manipulating and organizing carbon atoms. One commonly used method for producing carbon nanomaterials is chemical vapor deposition (CVD). In this process, a carbon-containing gas, such as methane or ethylene, is introduced into a high-temperature furnace. Within the furnace, the gas decomposes, releasing carbon atoms. Subsequently, these carbon atoms reform and create nanoscale structures, like carbon nanotubes or graphene, on a substrate or catalyst material. Another approach involves vaporizing carbon-containing compounds, such as carbon black or graphite, through techniques like laser ablation or arc discharge. The vaporized carbon then undergoes condensation and solidification, resulting in carbon nanomaterials with specific structures and properties. Both methods allow for precise manipulation of carbon atoms by controlling temperature, pressure, and the presence of catalysts or additives. This manipulation leads to the desired carbon nanomaterials, which possess exceptional mechanical, electrical, and thermal properties due to the unique arrangement of carbon atoms, such as the hexagonal lattice structure of graphene or the cylindrical structure of carbon nanotubes. In conclusion, carbon is a crucial element in carbon nanomaterial production, providing the necessary atoms and influencing their structure and properties. Understanding and controlling carbon's behavior at the atomic level empower scientists and engineers to develop nanomaterials with diverse applications, ranging from electronics and energy storage to medicine and environmental remediation.

- Q: How does carbon impact the availability of clean transportation?

- Carbon emissions from burning fossil fuels contribute to climate change, which affects the availability of clean transportation. Increased levels of carbon dioxide in the atmosphere trap heat, leading to rising global temperatures and extreme weather events. This, in turn, impacts the infrastructure necessary for clean transportation, such as roads, bridges, and railways. Additionally, carbon-intensive transportation systems, like gasoline-powered vehicles, contribute to air pollution, which further hinders the development and adoption of cleaner transportation alternatives like electric vehicles.

- Q: How does carbon affect food production?

- Carbon affects food production in several ways. Firstly, carbon dioxide is a crucial component for photosynthesis, the process by which plants convert sunlight into energy. Increased levels of atmospheric carbon dioxide can potentially enhance crop yields by providing plants with more raw materials for growth. However, excessive carbon emissions are also responsible for climate change, leading to extreme weather events such as droughts, floods, and heatwaves, which can negatively impact food production. Additionally, the burning of fossil fuels releases carbon dioxide, contributing to air pollution that can harm crops and reduce their productivity. Therefore, while carbon is essential for plant growth, the excessive release of carbon emissions can have detrimental effects on food production.

- Q: They include a cementite, two cementite, three cementite, eutectic cementite and eutectoid cementite, and compare their temperature, composition and morphology

- Two: cementite in iron graphite phase, carbon content more than 0.77%, in A (Fe + Fe3C) two-phase region precipitation of Fe3C is two times the cementite formation temperature in the eutectic temperature (1148 DEG C) and eutectoid temperature (727 DEG C), morphology of the mesh is a typical carbon content. From 0.77% to 6.69% is the typical composition range.

- Q: How does carbon affect the formation of tsunamis?

- The formation of tsunamis is not directly influenced by carbon. Tsunamis primarily occur as a result of underwater earthquakes, volcanic eruptions, or landslides. Carbon, in the form of carbon dioxide (CO2), is a greenhouse gas that contributes to global warming and climate change. Although carbon emissions and the resulting climate change can affect ocean temperatures and sea levels, they do not directly cause tsunamis. However, it is important to consider that climate change can indirectly impact the intensity and frequency of natural disasters, including tsunamis, by affecting oceanic and atmospheric conditions. The rising sea levels caused by melting glaciers and polar ice can potentially increase the destructive power of tsunamis by enabling them to reach further inland. Moreover, climate change can influence the occurrence and strength of earthquakes and volcanic activity, which are the main triggers of tsunamis. Therefore, even though carbon emissions do not directly influence the formation of tsunamis, their impact on climate change can indirectly affect the factors that contribute to the development and severity of tsunamis.

- Q: What is carbon black dye?

- Carbon black dye is a type of dye that is derived from carbon black, which is a fine black powder made from the incomplete combustion of hydrocarbon materials. It is commonly used as a pigment and dye in various industries, including the manufacturing of ink, paint, rubber, plastics, and textiles. Carbon black dye is highly valued for its intense black color and excellent lightfastness, meaning it does not fade easily when exposed to sunlight or other sources of light. Due to its strong coloring properties, carbon black dye is also used to add depth and darkness to other colors, making them more vibrant and visually appealing. Additionally, carbon black dye is known for its good heat stability, chemical resistance, and electrical conductivity, making it suitable for a wide range of applications.

- Q: What is carbon footprint labeling?

- The system of carbon footprint labeling provides consumers with information regarding the carbon emissions associated with a product or service. Its purpose is to educate consumers on the environmental impact of their purchases and empower them to make more sustainable choices. Typically, this labeling includes a measurement of the greenhouse gas emissions generated throughout the entire life cycle of a product, encompassing its production, transportation, and disposal. Consequently, consumers are able to compare the carbon footprints of various products and make well-informed decisions based on their environmental values. Carbon footprint labeling plays a vital role in promoting sustainability and urging businesses to reduce their emissions. Furthermore, it raises awareness about the influence that individual consumption choices have on climate change and encourages a transition towards more environmentally friendly alternatives.

- Q: What is carbon nanophotonics?

- Carbon nanophotonics is a branch of science and technology that focuses on the study and manipulation of light at the nanoscale using carbon-based materials. It involves the integration of carbon-based nanomaterials, such as carbon nanotubes, graphene, and diamond nanoparticles, with photonics to enable the development of novel optical devices and systems. The unique properties of carbon-based nanomaterials, such as their exceptional electrical conductivity, high mechanical strength, and excellent optical properties, make them ideal candidates for applications in nanophotonics. These materials have the ability to confine and manipulate light at the nanoscale, allowing for the miniaturization of optical components and the realization of enhanced light-matter interactions. Carbon nanophotonics has a wide range of potential applications across various fields. One prominent area is in telecommunications, where carbon nanomaterials can be used to develop high-speed and compact photonic devices for data transmission. Additionally, carbon nanophotonics has the potential to revolutionize the field of sensing by enabling the development of highly sensitive and selective sensors for detecting various molecules and substances. It also holds promise in the field of energy harvesting, where carbon nanomaterials can be utilized to enhance the efficiency of solar cells and other photovoltaic devices. Overall, carbon nanophotonics represents an exciting and rapidly evolving field that combines the unique properties of carbon-based nanomaterials with the principles of photonics to create innovative optical technologies. By harnessing the power of light at the nanoscale, carbon nanophotonics has the potential to revolutionize various industries and pave the way for new advancements in science and technology.

- Q: What are the different methods of measuring carbon dioxide levels in the atmosphere?

- There are several methods used to measure carbon dioxide levels in the atmosphere. These methods include direct measurement, remote sensing, and ice core analysis. Direct measurement is the most accurate and widely used method. It involves taking air samples from various locations around the world and analyzing them using gas analyzers. These analyzers can measure the concentration of carbon dioxide in the air, usually expressed in parts per million (ppm). Remote sensing is another method used to measure carbon dioxide levels. It involves using satellite-based instruments to observe and measure the amount of carbon dioxide in the Earth's atmosphere. These instruments can detect the absorption and scattering of sunlight by carbon dioxide molecules, providing valuable data on its concentration. Ice core analysis is a historical method of measuring carbon dioxide levels. Scientists drill deep into ice sheets in polar regions and extract ice cores. These ice cores contain trapped air bubbles from hundreds or thousands of years ago. By analyzing the carbon dioxide content in these bubbles, scientists can reconstruct past atmospheric carbon dioxide levels and compare them to present-day levels. Each of these methods has its advantages and limitations. Direct measurement provides real-time data and precise measurements, but it requires a vast network of monitoring stations worldwide. Remote sensing offers a global perspective and can cover large areas, but it may have limitations in resolving fine-scale spatial variations. Ice core analysis provides valuable long-term historical data, but it is limited to specific regions and can only provide indirect measurements. Combining these methods allows scientists to gain a comprehensive understanding of carbon dioxide levels in the atmosphere, helping us monitor and assess the impact of human activities on climate change.

- Q: The victory of the lightning 3361 material is full of carbon fiber, and the 3363 is made of carbon fiber and resin, which is better??

- All carbon fiber is good. The resin is only used for the badminton line, not for the racket.All carbon fiber material, is the most important material for badminton racket, all carbon fiber, good toughness, but also take into account the light performance.Carbon composite fiber, that is, in the carbon fiber added ordinary metal elements, such as aluminum, this material is relatively heavy, and toughness is not all carbon material.The best one is the carbon fiber material of racket frame which added to the rare metal, adding rare metal frame strong resilience, stability is better, and more suitable for double play.

Send your message to us

Calcined Anthracite Coal CA Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords