High Carbon Calcined Anthracite Coal Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Calcined Anthracite Description

This product is made from high-quality anthracite as raw materials, shape of columnar respectively, particles, powder, such as spherical shape, has high strength, adsorption speed, adsorption capacity, high specific surface area is larger, developed pore structure, pore size is between coconut shell activated carbon and wood charcoal.

Mainly used for high-end air purification, waste gas treatment, waste incineration, high pure water treatment, wastewater treatment, wastewater treatment, aquatic animals, desulphurization and denitration, and can effectively remove the impurities and contaminants in the gas and liquid as well as a variety of gas separation and purification, also can be widely used in all kinds of low boiling point substances adsorption recycling, deodorization oil removal, etc.

2.Main Features of the Calcined Anthracite

Calcined Anthracite is a kind of filter used in water treatment. It is suitable for the treatment of common acid, the middle degree alkali. This product has large surface area, and its various indexes all exceed the Construction Department’s standard. Anthracite filter is especially selected from the deep well minerals, so it includes the highest percentage of carbo. It must have been filtered and washed to make sure it can be used for water filting. Since it has better granular maintaining ability, so it can improve the floating granular’s cleaning ability.

3. Calcined Anthracite Images

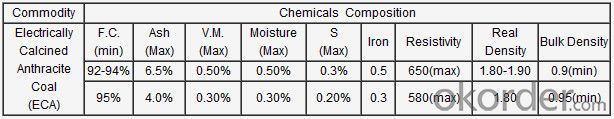

4. Calcined Anthracite Specification

5.FAQ of Calcined Anthracite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

- Q: Want advanced reinforcement, but I do not know where the high furnace rock carbon, looking for someone to guide...

- Mall. In fact, BUG can be card out! Inside the palace there is that BUG, but I personally think that no use, I used to strengthen the use of advanced carbon weapons on 12, even 3 did not become a storm, this is only the way to make money TX it

- Q: How does carbon contribute to the strength of concrete?

- Carbon contributes to the strength of concrete by reinforcing it through the formation of calcium silicate hydrate (C-S-H) gel. This gel fills in the gaps in the concrete matrix, enhancing its density and reducing porosity. Additionally, the carbonaceous material reacts with calcium hydroxide (a byproduct of cement hydration), producing calcium carbonate. The formation of calcium carbonate increases the overall strength and durability of the concrete structure.

- Q: How does carbon impact soil health?

- Carbon plays a crucial role in maintaining and improving soil health. It is a key component of organic matter, which is essential for fertile and productive soils. When carbon is added to the soil through the decomposition of plant and animal residues, it helps to improve the soil structure, water holding capacity, and nutrient availability. One of the primary ways carbon impacts soil health is through its ability to enhance soil structure. Carbon binds with soil particles to form aggregates, which create pore spaces in the soil. These pore spaces allow for better aeration, water infiltration, and root penetration. Good soil structure promotes the growth of beneficial soil organisms like earthworms and microorganisms, which further contribute to soil health. Carbon also plays a crucial role in improving the water holding capacity of soils. Organic matter, rich in carbon, acts as a sponge by holding moisture and preventing water runoff. This is particularly important in arid or drought-prone regions where water scarcity is a concern. Improved water retention in soils not only helps plants withstand dry periods but also reduces erosion and nutrient leaching. Furthermore, carbon is a vital nutrient for soil microbes. Microorganisms, such as bacteria and fungi, break down organic matter, releasing nutrients that are essential for plant growth. Carbon-rich soils provide a favorable environment for these microorganisms to thrive, leading to increased nutrient availability for plants. Additionally, as microorganisms decompose organic matter, they release beneficial substances like enzymes and hormones that further support plant growth and overall soil health. In conclusion, carbon greatly impacts soil health by improving soil structure, enhancing water holding capacity, and promoting nutrient availability. Therefore, managing and increasing carbon content in soils through practices like adding organic amendments, cover cropping, and reducing tillage can greatly benefit agricultural productivity and sustainability.

- Q: What is carbon black filler?

- Carbon black filler is a type of material made from fine particles of carbon that is added to various products, such as rubber, plastics, and inks, to improve their strength, durability, and color.

- Q: 14 is the upper left corner of the mark, please answer a bit more detailed, thank you!

- The fastest and easiest way:Enter 14C first, then select 14, and press CTRL+SHIFT+ '+'.

- Q: What are the properties of carbon-based ceramics?

- Carbon ceramics, also called carbon-based ceramics, are a distinct group of materials known for their exceptional properties, making them highly sought-after for various uses. These properties consist of: 1. Exceptional resistance to high temperatures: Carbon ceramics demonstrate remarkable thermal stability, enabling them to endure extremely high temperatures without significant deterioration or structural changes. This characteristic renders them ideal for applications in high-temperature environments like aerospace components, brake systems, and heat shields. 2. Low density: Carbon ceramics are characterized by their lightweight nature due to their low density. This quality proves advantageous in industries where weight reduction is essential, such as automotive and aerospace, as it enhances fuel efficiency and overall performance. 3. High hardness and resistance to wear: Carbon-based ceramics possess outstanding hardness and wear resistance, endowing them with durability and the ability to withstand abrasive forces. This attribute makes them suitable for use in cutting tools, bearings, and other applications that require resistance to wear and erosion. 4. Excellent resistance to chemicals: Carbon ceramics are renowned for their excellent chemical resistance, enabling them to withstand corrosion and degradation when exposed to aggressive chemical environments. This property proves valuable in industries like chemical processing, semiconductor manufacturing, and others that require resistance to chemical attack. 5. Good electrical conductivity: Unlike traditional ceramics, carbon-based ceramics exhibit good electrical conductivity due to the presence of carbon in their composition. This quality makes them useful in applications that necessitate both thermal insulation and electrical conductivity, such as heating elements, electrodes, and electronic components. 6. Customizable properties: Carbon ceramics offer the advantage of tailoring their properties to meet specific requirements by adjusting the composition and processing methods. Variables like carbon content, porosity, and microstructure can be modified to customize the mechanical, thermal, and electrical properties of carbon ceramics to suit particular application needs. In conclusion, carbon-based ceramics possess a unique set of properties, including high temperature resistance, low density, high hardness, excellent chemical resistance, good electrical conductivity, and the ability to customize their properties. These properties make them valuable materials across a wide range of industries, including aerospace, automotive, chemical processing, and electronics.

- Q: How does carbon impact the fertility of soil?

- Carbon plays a crucial role in the fertility of soil as it is the foundation of organic matter, which is vital for soil health and productivity. When carbon-rich organic matter, such as decaying plant and animal residues, is added to the soil, it helps improve its structure, nutrient-holding capacity, and water retention. This, in turn, enhances the soil's ability to support plant growth and sustain microbial activity. Organic matter serves as a source of carbon for soil microorganisms, fungi, and bacteria, which decompose it and release nutrients for plants. This decomposition process, known as mineralization, releases essential macronutrients (nitrogen, phosphorus, and potassium) and micronutrients into the soil, making them available for plant uptake. Additionally, carbon in organic matter helps bind soil particles together, improving soil structure and preventing erosion. Moreover, carbon improves the soil's water-holding capacity, reducing the risk of drought stress for plants. It acts as a sponge, absorbing and retaining moisture, which helps to sustain plant growth during dry periods. Carbon also promotes the development of a healthy and diverse soil microbial community, including beneficial bacteria and fungi. These microorganisms enhance nutrient cycling, disease suppression, and plant nutrient uptake, further contributing to soil fertility. However, excessive carbon inputs, such as from excessive organic matter addition or improper land management practices, can have negative effects on soil fertility. An imbalance in carbon availability can lead to nitrogen immobilization, where soil microorganisms consume nitrogen for their own growth, depriving plants of this essential nutrient. Additionally, high carbon content can create anaerobic conditions, reducing the availability of oxygen for plant roots and beneficial soil organisms. In summary, carbon is essential for maintaining soil fertility as it improves soil structure, nutrient availability, water retention, and microbial activity. However, it is crucial to maintain a balanced carbon-to-nitrogen ratio and adopt sustainable land management practices to ensure the optimal fertility of soil.

- Q: What are the alternatives to fossil fuels for energy production?

- There are several alternatives to fossil fuels for energy production, each with its own unique advantages and challenges. These alternatives include: 1. Renewable Energy Sources: Renewable energy sources, such as solar, wind, hydroelectric, and geothermal energy, harness the power of natural resources that are constantly replenished. Solar energy utilizes the sun's rays to generate electricity through photovoltaic cells, while wind energy converts the kinetic energy of wind into electrical power. Hydroelectric energy is generated by the force of flowing water, typically from dams or rivers, and geothermal energy taps into the heat generated by the Earth's core. These sources offer clean and virtually limitless energy, reduce greenhouse gas emissions, and promote energy independence. However, they may require a significant initial investment and have limitations based on geographic location and weather conditions. 2. Nuclear Energy: Nuclear power plants generate electricity through nuclear fission, which involves splitting atoms of uranium or plutonium to release energy. Nuclear energy is highly efficient and produces no greenhouse gas emissions during operation. It has the potential to provide consistent baseload power and can significantly reduce dependence on fossil fuels. However, it raises concerns about the storage and disposal of nuclear waste, the risk of accidents, and the potential for nuclear weapons proliferation. 3. Bioenergy: Bioenergy involves utilizing organic materials, such as agricultural waste, wood pellets, or dedicated energy crops, to produce heat, electricity, or biofuels. Biomass can be burned directly or converted into a gaseous or liquid form, such as biogas or bioethanol, to replace fossil fuels. Bioenergy has the advantage of being a readily available and carbon-neutral energy source. However, it may compete with food production, require large amounts of land, and raise concerns about deforestation and biodiversity loss if not managed sustainably. 4. Tidal and Wave Energy: Tidal and wave energy technologies harness the power of ocean currents and waves to generate electricity. These sources are predictable and have the potential to provide a consistent and reliable energy supply. However, the technology is still in its early stages, and high upfront costs, environmental impacts, and limited geographic availability can be challenges. 5. Hydrogen Fuel Cells: Hydrogen can be used as a fuel source in fuel cells to generate electricity. Hydrogen fuel cells combine hydrogen with oxygen from the air, producing electricity and water vapor as byproducts. Hydrogen is abundant and can be produced from various sources, including renewable energy. However, challenges include the high cost of production, storage, and distribution infrastructure, as well as the need for advancements in hydrogen storage technology. It is important to note that a combination of these alternative energy sources, along with improvements in energy efficiency and conservation, is likely to provide a more sustainable and resilient energy future, reducing our reliance on fossil fuels and mitigating the impacts of climate change.

- Q: What are the differences between the three carburizing, nitriding and carbonitriding? What are the different effects on the material?

- Carburizing: carburized workpiece after quenching and low temperature tempering, so that the surface has a high hardness of river abrasion resistance, and the heart still maintain a good plastic River toughness, so as to meet the workpiece outside the hard, internal use of tough requirementsNitriding: after the nitriding of the parts, the surface forms a nitride.

- Q: How does carbon affect the color of gemstones?

- Carbon can affect the color of gemstones by either enhancing or modifying their natural hues. When present as impurities or inclusions, carbon can give gemstones a yellow or brown color. However, when arranged in a specific crystal lattice, carbon can create exceptional colorless or white gemstones, such as diamonds.

Send your message to us

High Carbon Calcined Anthracite Coal Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords