Calcined Aanthracite Used as Charge Coke FC82-90%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

25kgs/50kgs/1ton per bag or as buyer's request

Specifications

Calcined Anthracite

Fixed carbon: 90%-95%

S: 0.5% max

Size: 0-3. 3-5.3-15 or as request

It used the high quality anthracite as raw materials through high temperature calcined at over 2000 by the DC electric calciner with results in eliminating the moisture and volatile matter from anthracite efficiently, improving the density and the electric conductivity and strengthening the mechanical strength and anti-oxidation. It has good characteristics with low ash, low resistvity, low sulphur, high carbon and high density. It is the best material for high quality carbon products.

Advantage and competitive of caclined anthracite:

1. strong supply capability

2. fast transportation

3. lower and reasonable price for your reference

4.low sulphur, low ash

5.fixed carbon:95% -90%

6..sulphur:lower than 0.3%

General Specification of Calcined Anthracite:

| FC | 90 | 88 | 85 | 83 | 82 |

| ASH | 8.5 | 10 | 12 | 14 | 15 |

| V.M. | 1.5 | 2 | 3 | 3 | 3 |

| S | 0.35 | 0.5 | 0.5 | 0.5 | 0.5 |

| MOISTURE | 0.5 | 1 | 1 | 1 | 1 |

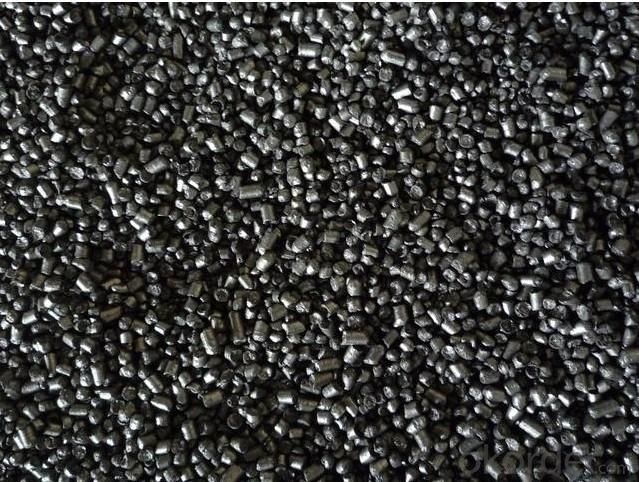

Pictures

Advantage:

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: Glucose contains resveratrol (C14H12O3) to determine the mass ratio of resveratrol and carbon dioxide of the same quality as carbon dioxide

- They are x and y, containing carbon equal, according to the mass of an element = the mass of a compound * the elementMass fractionFor C14H12O3, the carbon mass fraction is C%=12*14/ (12*14+12+16*3) *100%=73.68%For CO2, the mass fraction of carbon is 12/ (12+16*2) =27.27%There is x *73.68%=y*27.27%So there's X: y =57:154

- Q: What is electrical carbon?

- The main component of electrical carbon material is carbon. Because of the different structures, carbon has two types: crystalline carbon and amorphous carbon. Crystalline carbon is mainly composed of graphite, amorphous carbon, mainly coke, charcoal, carbon black and so on. Coal used daily is an impure amorphous carbon.Graphite has a crystalline structure of six square system. It has numerous parallel layers superimposed on each layer of carbon atoms at the top angles of the six angles plane, forming an ordered arrangement of three-dimensional space. Because the distance between the layers of the graphite crystal is much larger than the distance between the carbon atoms on the surface, the graphite has an obvious anisotropy. When there is external force, the surface of graphite is easy to slip, so it shows self lubrication characteristics. In high purity graphite crystals, the valence band overlaps the conduction band, so the high conductivity of the metalloid is demonstratedThe arrangement of carbon atoms in amorphous carbon is haphazard, and it is easier to slip than the graphite layer, and its hardness is 4~5 times higher than that of graphite. Amorphous carbon, if treated at 2 200~2 5000C high temperature, can transform the disordered structure into an ordered arrangement of two-dimensional space.

- Q: How does carbon impact the prevalence of droughts?

- Carbon impacts the prevalence of droughts by contributing to climate change. Increased levels of carbon dioxide in the atmosphere trap heat and lead to rising global temperatures. This enhanced greenhouse effect alters weather patterns and increases the frequency and severity of droughts in many regions around the world.

- Q: What is the carbon footprint?

- The carbon footprint is a measure of the total greenhouse gases, specifically carbon dioxide (CO2), that are released into the atmosphere due to human activities. It quantifies the impact individuals, organizations, or countries have on the environment by contributing to climate change. This impact encompasses both direct emissions from burning fossil fuels for transportation, heating, and electricity, as well as indirect emissions from the production and transportation of goods and services we consume. Measured in units of carbon dioxide equivalent (CO2e), the carbon footprint serves as a vital tool for assessing and managing our environmental influence. By comprehending and diminishing our carbon footprint, we can alleviate climate change and strive for a more sustainable future.

- Q: What are the different forms of carbon?

- There are multiple variations of carbon known as allotropes. Diamond, graphite, and amorphous carbon are the most common types. Diamond, the hardest natural substance, is made up of carbon atoms arranged in a crystal lattice structure. It is highly refractive and often used for its brilliance and clarity in jewelry. On the other hand, graphite has a layered structure where carbon atoms form sheets. It is a soft and slippery material commonly found in pencils and lubricants. Graphite is also an excellent conductor of electricity, making it suitable for batteries and electrodes. Amorphous carbon refers to carbon materials without a well-defined crystal structure. Examples include charcoal, soot, and activated carbon. These forms have diverse applications, such as water and air purification, as well as the manufacturing of electrodes and pigments. There are also other forms of carbon, like fullerenes and carbon nanotubes, which have unique properties and are extensively researched for potential applications in nanotechnology and electronics. To summarize, carbon can have various forms due to its atomic arrangement, resulting in materials with distinct physical and chemical properties. These forms of carbon are used across different industries and play a vital role in our daily lives.

- Q: Material characteristics of carbon fiber

- Carbon fiber is a kind of new material with excellent mechanical properties due to its two characteristics: carbon material, high tensile strength and soft fiber workability. The tensile strength of carbon fiber is about 2 to 7GPa, and the tensile modulus is about 200 to 700GPa. The density is about 1.5 to 2 grams per cubic centimeter, which is mainly determined by the temperature of the carbonization process except for the structure of the precursor. Generally treated by high temperature 3000 degrees graphitization, the density can reach 2 grams per cubic mile. Coupled with its weight is very light, it is lighter than aluminum, less than 1/4 of steel, than the strength of iron is 20 times. The coefficient of thermal expansion of carbon fiber is different from that of other fibers, and it has anisotropic characteristics. The specific heat capacity of carbon fiber is generally 7.12. The thermal conductivity decreases with increasing temperature and is negative (0.72 to 0.90) parallel to the fiber direction, while the direction perpendicular to the fiber is positive (32 to 22). The specific resistance of carbon fibers is related to the type of fiber. At 25 degrees centigrade, the high modulus is 775, and the high strength carbon fiber is 1500 per centimeter.

- Q: How is carbon dioxide released into the atmosphere?

- Carbon dioxide is released into the atmosphere through a variety of natural and human activities. One of the primary sources of carbon dioxide is the burning of fossil fuels such as coal, oil, and natural gas for energy production. When these fuels are burned, carbon dioxide is released as a byproduct of combustion. This happens in power plants, factories, and vehicles that rely on these fossil fuels for energy. Deforestation and land-use changes also contribute to the release of carbon dioxide into the atmosphere. Trees absorb carbon dioxide through photosynthesis, and when they are cut down or burned, the stored carbon is released back into the atmosphere. This is particularly significant in tropical rainforests, where large amounts of carbon are stored in vegetation. Additionally, natural processes such as respiration and volcanic eruptions release carbon dioxide into the atmosphere. Respiration is the process by which living organisms, including humans and animals, breathe in oxygen and exhale carbon dioxide as a waste product. Volcanic eruptions release carbon dioxide stored in magma and rock formations. Overall, the release of carbon dioxide into the atmosphere is a combination of both natural and human activities. However, human activities, particularly the burning of fossil fuels and deforestation, have significantly increased the levels of carbon dioxide in the atmosphere, leading to the greenhouse effect and climate change.

- Q: How is carbon used in the production of paints?

- Paint production utilizes carbon in multiple ways. An important application of carbon in paint production involves its use as a pigment. Carbon black, a type of elemental carbon, is commonly employed as a black pigment in various paint types. It imparts a deep and intense black hue, along with exceptional light absorption characteristics, making it ideal for creating dark tones in paints. Additionally, carbon plays a role in the formulation of specific paint types, such as carbon-based coatings. These coatings find application in scenarios demanding resistance against heat, chemicals, and corrosion. Industries like automotive, aerospace, and marine frequently employ carbon-based coatings, where durability and protection are paramount. These coatings can be applied to diverse surfaces, providing a high level of protection and extending the lifespan of the painted object. Furthermore, carbon serves as a filler material in certain paint varieties. Carbon fillers are added to enhance the mechanical properties of the paint, including strength, hardness, and resistance to wear and tear. They also contribute to the overall performance of the paint, augmenting its durability and longevity. In conclusion, carbon is an indispensable component in paint manufacturing, fulfilling roles as a pigment, a constituent of coatings, and a filler material. Its versatile properties make it a valuable addition to various paint formulations, enhancing the aesthetic appeal, durability, and performance of the final product.

- Q: How does carbon affect the acidity of oceans?

- The acidity of oceans is greatly influenced by carbon dioxide (CO2). Human activities like burning fossil fuels and deforestation release CO2 into the atmosphere, a significant portion of which is absorbed by the oceans. This absorption, known as ocean acidification, causes an increase in hydrogen ions in the water, leading to lower pH levels and higher acidity. When CO2 dissolves in seawater, it combines with water molecules to create carbonic acid (H2CO3). This chemical reaction releases hydrogen ions (H+), which elevate the water's acidity. The increased acidity disrupts the delicate chemical balance necessary for life in the ocean, especially reactions involving calcium carbonate. Calcium carbonate plays a vital role in the formation of shells and skeletons for various marine organisms, such as corals, shellfish, and certain plankton. As ocean acidity rises, it becomes more challenging for these creatures to construct and maintain their calcium carbonate structures. This can result in stunted growth, weakened shells, and heightened susceptibility to predators and diseases. Ocean acidification also has implications for the entire marine food chain. Many species depend on shell-forming organisms as a food source or as habitats, and their decline can have a ripple effect on the entire ecosystem. Additionally, acidification can disrupt the balance of phytoplankton, which are microscopic plants crucial for marine food chains. Furthermore, carbon dioxide in the ocean can interact with water to generate bicarbonate ions (HCO3-) and carbonate ions (CO32-). These ions are crucial for maintaining proper pH levels and enabling marine organisms to regulate their internal chemistry. However, as CO2 levels increase, the concentration of carbonate ions decreases, making it more challenging for organisms to obtain the carbonate they need to build their shells and skeletons. Overall, the impact of carbon on ocean acidity is significant and has far-reaching consequences for marine life. It is essential to reduce carbon emissions and implement measures to mitigate and adapt to the effects of ocean acidification in order to safeguard the health and biodiversity of our oceans.

- Q: How does carbon impact the availability of clean air?

- Carbon impacts the availability of clean air by contributing to the formation of air pollutants such as carbon dioxide (CO2) and carbon monoxide (CO). These greenhouse gases trap heat in the atmosphere, leading to global warming and climate change. Additionally, carbon emissions from burning fossil fuels and other human activities can react with sunlight and other pollutants, forming ground-level ozone and particulate matter, which can negatively affect air quality and human health. Therefore, reducing carbon emissions is crucial to maintaining clean air and mitigating the adverse impacts of pollution.

Send your message to us

Calcined Aanthracite Used as Charge Coke FC82-90%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches