Raw Materials for Refractory Calcination Rotary Kiln for Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Production Capacity: | Refer to specification | Place of Origin: | Henan, China (Mainland) |

| Brand Name: | cnbm | Model Number: | Refer to specification | Voltage: | 220 |

| Power(W): | Refer to specification | Dimension(L*W*H): | according to models | Weight: | various |

| Certification: | CE,ISO9001 | Warranty: | one year | After-sales Service Provided: | Engineers available to service machinery overseas |

| Calcination rotary kiln for bauxite: | high efficiency | Factory: | 50,000 square meters closed workshops | Technology: | 30 years experienced technology support |

| Technical service: | the whole using life | Product supply: | crushing machine, grinding machine, ore dressing equipment | Grinding machine: | Raymond mill, ball mill, coal mill |

| rotation speed: | 0.10-3r/min | capacity: | 0.9-42t/h | Workers: | more than 660 |

| Experts: | more than 80 with senior engineering technicians |

Packaging & Delivery

| Packaging Details: | standard containers, bare main machine, motors and small parts are packed in wooden cases. |

| Delivery Detail: | 5~25 working days after placing the order |

Specifications

Calcination rotary kiln for bauxite

1.Good sealability

2.Precise control,energy saving

3.CE,ISO

4.30 year experience

Product Description

Features of calcination rotary kiln for bauxite

1) It is an inclined rotary cylinder, the raw material enter the cylinder through the high end of the machine,then move in with the movement of of the rotary kiln. Therefore, the rotary kiln is a conveying equipment.

2) It is a combustion device.

3) It has the function of heat exchange.

4) It has the chemical reaction function.

5) It has the function of degrading and re-using the waste.

Advantages of calcination rotary kiln for bauxite

◊. Energy-saving and environmental-protection, using wastes as fuel

◊. Solid structure, stable operation

◊. High-usage of thermal energy

Application of calcination rotary kiln for bauxite

1. Rotary kiln is commonly used in the production process of catalytic agent, molecular sieve and zinc oxide, etc.

As a result, you can find rotary kiln for bauxite in variety of industries, like steel annealing and nonferrous smelting industries, metallurgy and chemistry fields, and building industries, and more.

2. Rotary kiln system, which is also called a rotary calcine kiln, is a commonly used building material machine. Classifying by material properties, a rotary kiln falls into cement kilns, metallurgy chemical kilns, and lime kilns.

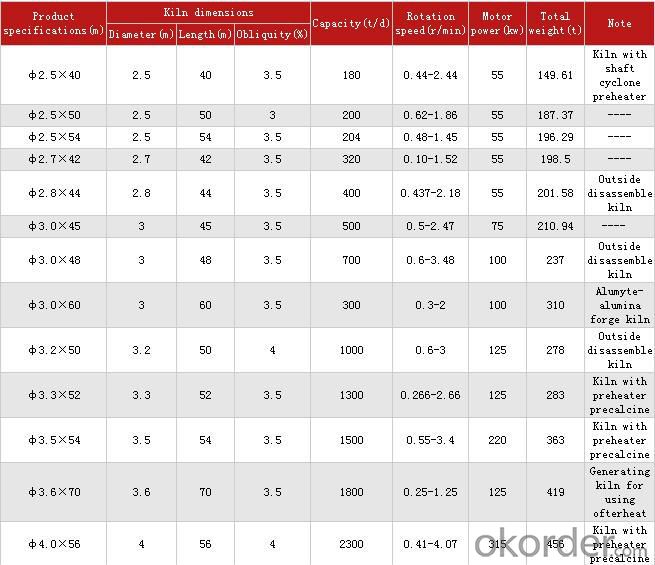

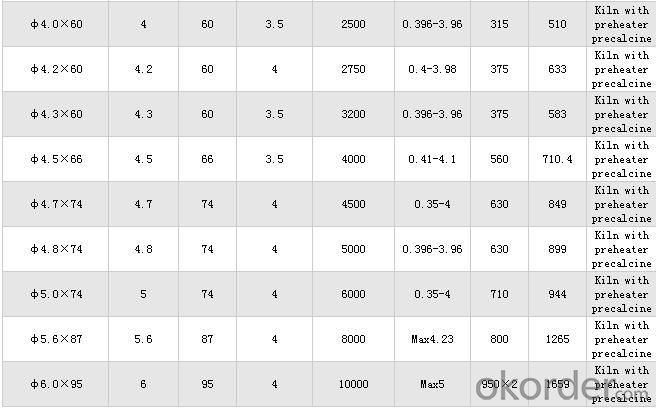

Technical parameters of calcination rotary kiln for bauxite

- Q: hat kind of fire retardant materials are there

- At present, there are mainly organic and inorganic flame retardant materials, halogen and non halogen. Organic flame retardant materials are represented by bromine, nitrogen and phosphorus and its compounds; Inorganic fire retardant materials include antimonous oxide, magnesium hydroxide, aluminum hydroxide, and silicon. Generally speaking, organic flame retardant materials have a good affinity, and can be added in the plastics. Brominated flame retardant agent occupy the absolute advantage among organic flame retardant system, though it’s “controversial” in terms of environmental protection, it has been difficult to have other flame retardant system replaced.

- Q: What are the electrical fire protection materials?

- Electrical fire protection materials are the following: 1, fire proof board It is the most commonly used materials in the market, which has the advantages of fire prevention, moisture, abrasion, oil, easiness to clean, and more varieties of colors. Installed in the building exit corridors, stairs and corridors, such as fire ceiling ceiling, it can ensure that people can be evacuated safely, and to protect people from the spread of the fire. 2, fire proof door, fire proof door is divided into wooden fire door, steel fire door and stainless steel fire door. Fire proof doors are usually used for the opening of the firewall, the entrance of the staircase, the evacuation of the aisle, the openings and other parts of the pipeline, the fire prevention, playing an important role in reducing the loss of fire. 3, fire shutter It can be set in the location where it is not convient to install a fire proof wall, fire shutter generally has functions such as good fire resistance, heat insulation, smoke, compression, anti aging, wear and corrosion. 4, fireproof and mothproof wood fire wood moth is made by putting ordinary wood into the solution containing calcium and aluminum, and then into the solution containing phosphate and silicate. In this way, two ion will be undergong chemical reaction in the wood, forming materials similar to the ceramic, and filling the gap of cells and tissues, so that allowing it to have fireproof and mothproof performance.

- Q: Can quantitative feeder be used in refractory plant? Thank you

- Feeder experts, justice and analysis, quantitative feeder, of course, can be used in refractory plants

- Q: How to distinguish the fire resistant level of the rubber and plastic thermal insulation material?

- It is divided into level A, B1, B2 and B3. According to the current "burning behavior of building materials classification method", Level A insulation material is a non-combustible material, which belongs to YT. However, from the point of view of the current market , level A insulation material are very few, only glass wool, rock wool board, foam glass and vitrified micro bead. However, compared with level A insulation material, the more welcomed by the market is the organic insulation material. This is characterized as thermal insulation material, which is divided into three levels: level B1 is flame retardant, level B2 is flammable and level B3 is flammable. The level B1 nonflammable thermal insulation material is determined according to the fire endurance of the material. And different parts of the material are divided differently! Such as the common EPS / XPS insulation boards through special treatment of adding flame retardant. . Level B2 combustible insulation material is commonly the EPS expanded polystyrene foam insulation board and XPS board, that is, the ordinary plate. This material has low ignition point, and releases large amounts of harmful gases in the combustion process . Level B3 flammable insulation material is commonly the thermal insulation material taking polystyrene foam as the main material. Since this material is highly flammable, it has been out of the external wall thermal insulation materials. As for the civil construction insulation materials, China's current popular building insulation materials in the market are mainly made of three organic foams: EPS (molded polystyrene board), XPS (extruded polystyrene board) and PU (polyurethane).

- Q: Refractory materials are needed for casting metallurgy.

- High quality refractory materials can not be separated from the process of smelting metal and casting moulding, because the quality of melting furnace, iron / steel ladle directly affect the chemical composition of the metal liquid, and exert irretrievable influence on comprehensive quality of castings. Classification of refractory materials used in foundry smelting process: refractory brick, siliceous brick, high alumina brick, corundum brick, magnesia brick, magnesia brick, magnesia carbon brick. Unshaped refractory materials: ramming material, castable, refractory cement, silica, magnesia, coating material and light insulation material etc.

- Q: Who knows how to divide the building fire grade and fire resistance grade?

- I hope to help you building fireproof rank division is one of the most basic measure in building fire safety technical measures, Building's fireproof rank is divided into class one, two, three, four according to China's architectural design specification. Fire-resistant capability of the highest level is the strongest; Fire resistance of four level of the weakest. The fire resistance level of a building depends on the combustion performance and fire resistance of the building components that comprise the building. The so-called building component refers to a series of basic components, such as wall, foundation, beam, column, floor, stair, ceiling and so on. The judgment condition of the fire resistance There are three conditions for components' fire resistance limit to be reached, namely, the fire resistance limit of the building component: Loss of support and integrity; loss of time to fire the role of the time; as long as any of these three conditions is met, it will reach its limit of fire. Hope my answer will help you.

- Q: The development prospect of fire-resistant material

- Exported bulk material amounts to exported raw material/ To protect domestic resources, many countries have set linitations on the magnesium content in shapeless refractory material and lisences.

- Q: Which kind of refractory floor is easy to use? ?

- Recommend: Yong Wei fireproof board Henan Yong Wei Anfang Co., Ltd., located in Qinbei industrial agglomeration area, Qinyang City, Henan Province, was founded in 1995. It strated from the initial one fire decorative plate production line. After years of development, it has become the biggest fireproof decorative board production base with 25 fireproof board production lines.

- Q: What parts of cement kilns are refractories used on?

- In kilns.

- Q: what's the requirements of refractory for forge furnace?

- . . . . . . . .

Send your message to us

Raw Materials for Refractory Calcination Rotary Kiln for Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords